12 月 . 04, 2024 09:27

Back to list

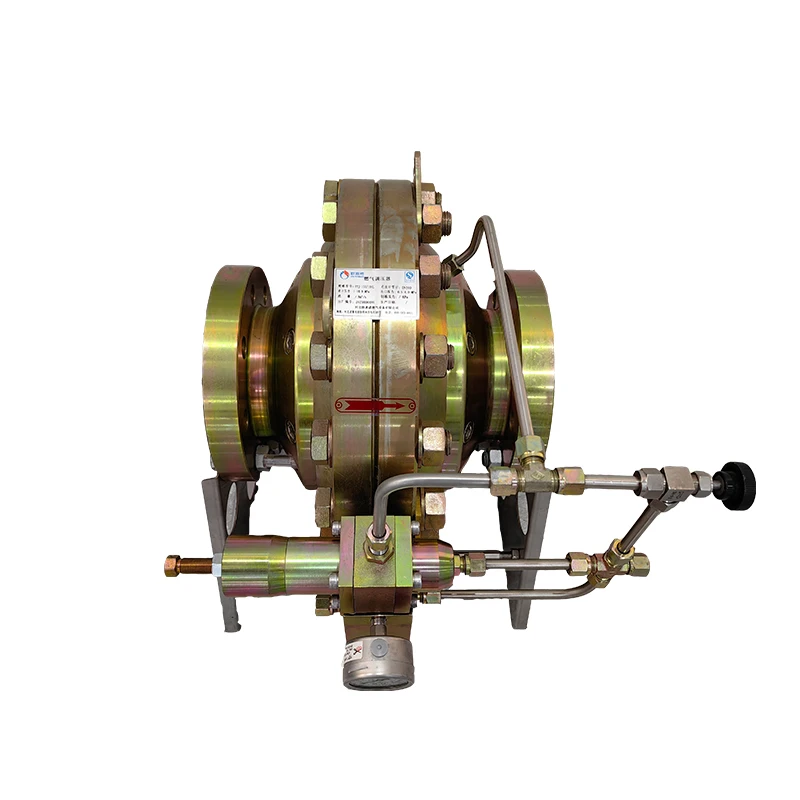

صمام الإغلاق

The Importance of Shut-off Valves in Industrial Applications

Shut-off valves play a critical role in various industrial applications, ensuring safety and efficiency in systems where fluid control is essential. These valves are designed to either completely stop or allow the flow of liquids or gases through a pipeline. Their importance cannot be overstated, as they are pivotal in managing processes across different sectors, including oil and gas, water treatment, chemical manufacturing, and more.

What are Shut-off Valves?

Shut-off valves are mechanical devices that regulate the flow of fluids in a piping system. They come in various designs, including ball valves, gate valves, globe valves, and butterfly valves, each serving different purposes based on the specific requirements of the system. The primary function of these valves is to either isolate a section of the piping system for maintenance or to control the flow of substances, ensuring that operations can be conducted safely and effectively.

Key Functions and Benefits

.

2. Flow Control Shut-off valves are essential for controlling the flow of fluids in a system. By adjusting the valve, operators can regulate pressure, temperature, and volume, ensuring that processes operate within optimal parameters. This is particularly crucial in industries like chemical manufacturing, where precise control can significantly impact product quality.

صمام الإغلاق

3. Maintenance and Repair Regular maintenance is essential for any industrial system, and shut-off valves facilitate this by allowing sections of the system to be isolated without shutting down the entire operation. This feature saves time and reduces downtime, enabling continuous production and minimizing financial losses.

4. System Efficiency Efficient operations are paramount in competitive industries, and shut-off valves contribute to this efficiency. By minimizing leaks and optimizing flow control, these valves help achieve energy savings and reduce operational costs.

Applications of Shut-off Valves

Shut-off valves are utilized in numerous industries. In the oil and gas sector, they are used to isolate sections of pipelines, particularly in emergency shutdown situations. In water treatment facilities, they manage water flow through various stages of the treatment process. Chemical manufacturing relies on these valves for controlling reactions and preventing the unintentional release of hazardous materials.

In addition, shut-off valves are essential in HVAC systems, where they regulate airflow and temperature in buildings, and in food and beverage processing, where they ensure hygiene and quality control.

Conclusion

In summary, shut-off valves are indispensable components in a wide range of industrial applications. Their ability to ensure safety, control flow, and facilitate maintenance makes them a crucial part of any piping system. As industries continue to evolve and face new challenges, the role of shut-off valves will only become more significant. Investing in high-quality shut-off valves and ensuring their proper maintenance is essential for enhancing operational efficiency, maximizing safety, and ensuring compliance with industry regulations. Thus, understanding and implementing effective shut-off valve solutions is vital for the sustainability and success of industrial processes.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024