12 月 . 06, 2024 03:12

Back to list

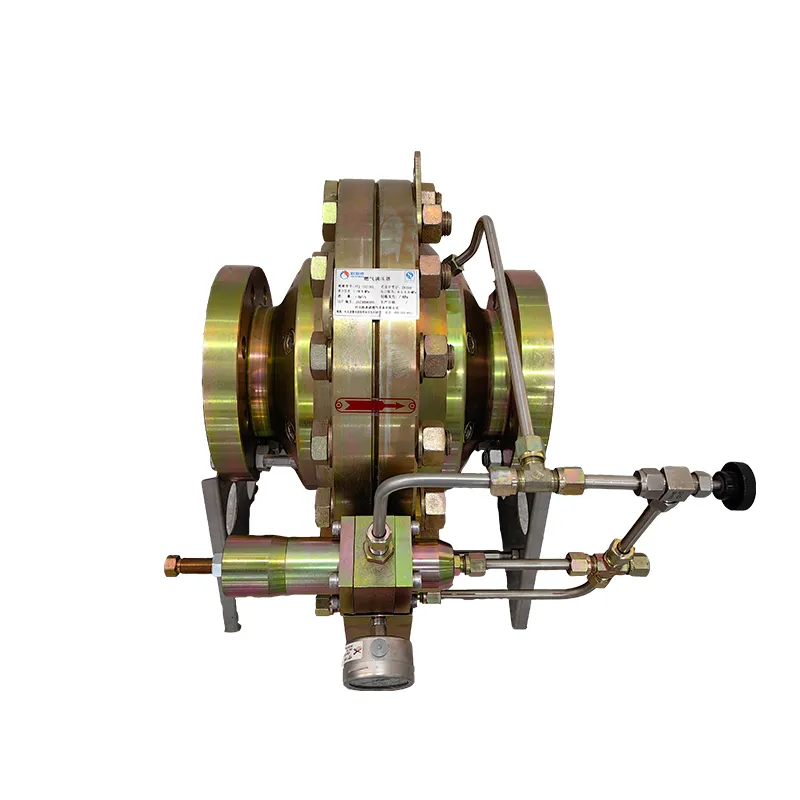

صمام التحكم الهوائي

The Pneumatic Control Valve An Essential Component in Modern Automation

Pneumatic control valves are critical devices in various industrial applications, playing a pivotal role in the management and regulation of pneumatic systems. These valves control the flow and pressure of compressed air or gas, making them indispensable in sectors such as manufacturing, automotive, and food processing. This article delves into the functionality, types, applications, and advantages of pneumatic control valves, emphasizing their importance in modern automation.

Understanding Pneumatic Control Valves

At its core, a pneumatic control valve is designed to modulate airflow, directing it to specific machinery or processes. These valves are operated through pneumatic signals, which means they respond to changes in pressure to open, close, or regulate flow. The primary components of a pneumatic control valve include the actuator, the control element (valve body), and the feedback mechanism. The actuator translates pneumatic signals into mechanical movement, while the valve body facilitates airflow. The feedback mechanism ensures precision by transmitting information about the valve position back to the control system.

Types of Pneumatic Control Valves

Pneumatic control valves come in various types, each suited to different applications

1. On/Off Valves These are the simplest form of control valves, either fully opened or closed. They are commonly used in systems requiring a binary action, such as starting or stopping the flow of air.

2. Flow Control Valves These valves enable precise regulation of airflow. They can be manually adjusted or automatically controlled via sensors, allowing for optimal system performance.

3. Pressure Control Valves These valves maintain a specified pressure level within the system. They are vital in applications where consistent pressure is crucial for operation, such as in hydraulic systems.

4. Solenoid Valves Utilizing electromagnetic coils to open or close the valve, solenoid valves are widely used for rapid operation and automation in pneumatic circuits.

.

Applications of Pneumatic Control Valves

صمام التحكم الهوائي

The versatility of pneumatic control valves enables their use across diverse industries. In manufacturing, these valves control the operation of machinery and assembly lines, enhancing efficiency and productivity. In the automotive sector, they manage the functions of pneumatic tools and systems, optimizing performance.

Moreover, in the food processing industry, pneumatic control valves regulate the flow of air or gas in packaging and production lines, ensuring the safety and quality of food products. Additionally, they are crucial in the pharmaceutical industry, where precise control of airflow is necessary to maintain sterile environments.

Advantages of Pneumatic Control Valves

Pneumatic control valves offer numerous advantages, making them invaluable in industrial applications

1. Efficiency By providing precise control over airflow and pressure, pneumatic control valves enhance the efficiency of processes, reducing waste and energy consumption.

2. Speed These valves can operate quickly, allowing for rapid changes in airflow which is essential in dynamic industrial environments.

3. Durability Designed to withstand harsh conditions, pneumatic control valves are often robust and reliable, ensuring long-term operation with minimal maintenance.

4. Safety Pneumatic systems can be inherently safer than hydraulic systems due to the lower risk of leaks and spills associated with compressed air compared to hydraulic fluids.

5. Cost-Effectiveness While initial investment may vary, the long-term savings in energy efficiency, reduced maintenance, and increased productivity make pneumatic control valves a cost-effective choice.

Conclusion

In conclusion, pneumatic control valves are integral to the functioning of modern automation systems. Their ability to control airflow with precision offers significant benefits in efficiency, speed, durability, safety, and cost-effectiveness. As industries continue to embrace automation and advanced manufacturing processes, the importance of pneumatic control valves is poised to grow even further, driving innovation and enhancing productivity across diverse sectors. Understanding and leveraging these devices will be crucial for businesses looking to optimize their operations and maintain a competitive edge in the marketplace.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024