1 月 . 19, 2025 23:42

Back to list

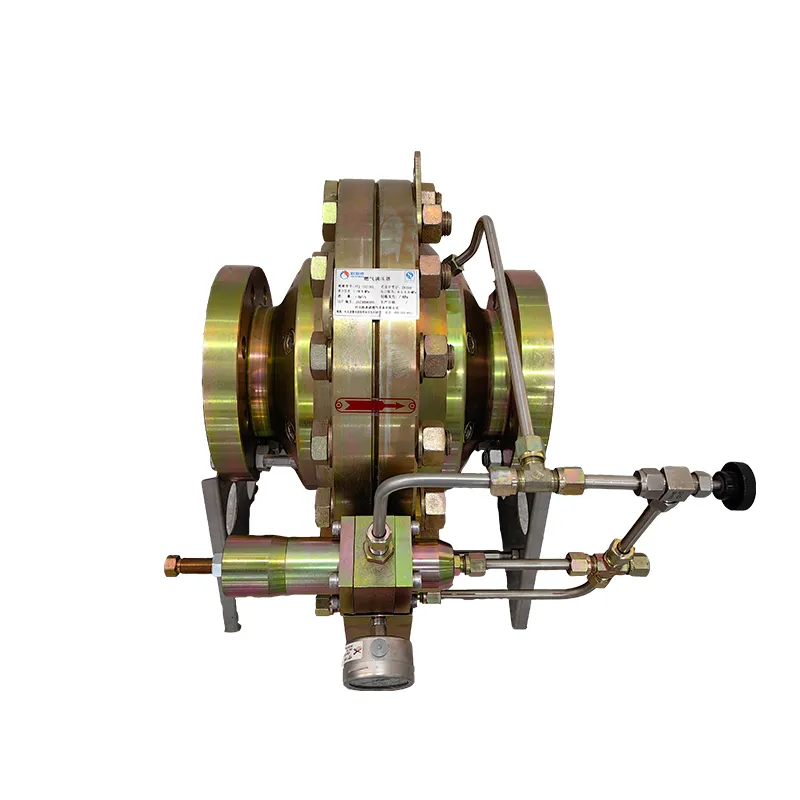

صمام تخفيض الضغط

Pressure reducing valves, known as صمام تخفيض الضغط in Arabic, are critical components in numerous industrial and residential applications. Their primary function is to reduce the input pressure of a fluid or gas to a manageable level, ensuring safety and efficiency in various systems. This article delves into their importance, specific applications, and what to consider when choosing the right valve for a specific need.

A visit to modern manufacturing plants reveals that pressure reducing valves today incorporate cutting-edge technology, offering adjustable settings that provide flexibility and adaptability. This level of precision ensures that no matter the fluctuations in input pressure, the desired output pressure remains constant, thereby streamlining operations and enhancing productivity. Safety features in contemporary valves are also worth noting. Many now come with built-in pressure gauges for real-time monitoring and automatic shut-off capabilities to avert any potential disasters due to pressure anomalies. This focus on enhanced safety aligns with industry standards and regulatory requirements, making them indispensable in risk management. The authority imbued in leading valve manufacturers stems from years of experience and rigorous testing that adheres to international quality certifications. Their dedication to creating reliable, durable products fosters trust among industries reliant on seamless operational processes. It's not simply about offering a product; it’s about providing assurances of performance excellence and reliability, which are cornerstones of their reputation. Conducting a thorough assessment before procuring a pressure reducing valve is imperative. Consulting specialists or engineers to evaluate system requirements and forecast future demand ensures the chosen valve not only meets current needs but is also scalable if system demands grow. In conclusion, pressure reducing valves are indispensable in both industrial and residential applications, serving as a critical control measure against the adverse effects of pressure discrepancies. Their contributions towards operational safety, system efficiency, and equipment longevity underscore their value. Investing in the right pressure reducing valve, backed by expert advice and manufactured by a reputable company, ensures maintenance of high industry standards, safety protocols, and ultimately, peace of mind for users.

A visit to modern manufacturing plants reveals that pressure reducing valves today incorporate cutting-edge technology, offering adjustable settings that provide flexibility and adaptability. This level of precision ensures that no matter the fluctuations in input pressure, the desired output pressure remains constant, thereby streamlining operations and enhancing productivity. Safety features in contemporary valves are also worth noting. Many now come with built-in pressure gauges for real-time monitoring and automatic shut-off capabilities to avert any potential disasters due to pressure anomalies. This focus on enhanced safety aligns with industry standards and regulatory requirements, making them indispensable in risk management. The authority imbued in leading valve manufacturers stems from years of experience and rigorous testing that adheres to international quality certifications. Their dedication to creating reliable, durable products fosters trust among industries reliant on seamless operational processes. It's not simply about offering a product; it’s about providing assurances of performance excellence and reliability, which are cornerstones of their reputation. Conducting a thorough assessment before procuring a pressure reducing valve is imperative. Consulting specialists or engineers to evaluate system requirements and forecast future demand ensures the chosen valve not only meets current needs but is also scalable if system demands grow. In conclusion, pressure reducing valves are indispensable in both industrial and residential applications, serving as a critical control measure against the adverse effects of pressure discrepancies. Their contributions towards operational safety, system efficiency, and equipment longevity underscore their value. Investing in the right pressure reducing valve, backed by expert advice and manufactured by a reputable company, ensures maintenance of high industry standards, safety protocols, and ultimately, peace of mind for users.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024