1 月 . 20, 2025 00:27

Back to list

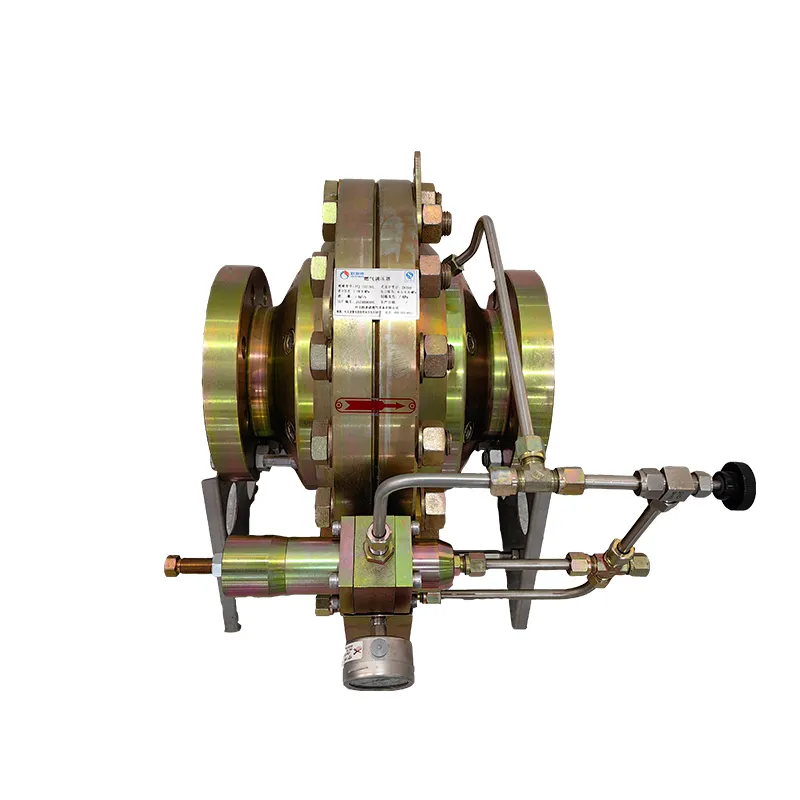

منظم الضغط

Organizing pressure in hydraulic or pneumatic systems is critical in ensuring safe and efficient operations, whether it's in industrial machinery, automotive systems, or home appliances. The component tasked with this vital function is known as a pressure regulator. Recognized for its significance across various sectors, a pressure regulator acts as an essential device that maintains the appropriate pressure levels within a system, thus optimizing performance and preventing malfunctions.

From an authoritative perspective, it's essential to reference credible sources and comply with industry standards when choosing and installing pressure regulators. Regulatory bodies often provide guidelines and certifications to ensure the regulators are suitable for their intended applications. Consulting technical datasheets and manufacturer manuals offers valuable insights and helps maintain compliance with safety standards. Trustworthiness in pressure regulation is non-negotiable. Reliable manufacturers undergo rigorous testing and quality assurance processes to guarantee their products meet high performance and safety standards. Customer reviews and testimonials can also provide an added layer of trust, as they often reflect user satisfaction and product reliability over extended periods. In conclusion, the effective organization of pressure within a system is a multi-faceted endeavor that blends experience, expertise, authoritative compliance, and trust. By focusing on these key aspects, industries can achieve optimal system performance, enhance safety, and improve operational efficiencies. Whether it's for industrial applications or everyday use, pressure regulators remain an indispensable tool in managing pressure effectively, ensuring seamless and trouble-free operation. For anyone involved in selecting and maintaining pressure regulators, staying informed with the latest technologies and best practices is vital for achieving sustainable and top-tier results.

From an authoritative perspective, it's essential to reference credible sources and comply with industry standards when choosing and installing pressure regulators. Regulatory bodies often provide guidelines and certifications to ensure the regulators are suitable for their intended applications. Consulting technical datasheets and manufacturer manuals offers valuable insights and helps maintain compliance with safety standards. Trustworthiness in pressure regulation is non-negotiable. Reliable manufacturers undergo rigorous testing and quality assurance processes to guarantee their products meet high performance and safety standards. Customer reviews and testimonials can also provide an added layer of trust, as they often reflect user satisfaction and product reliability over extended periods. In conclusion, the effective organization of pressure within a system is a multi-faceted endeavor that blends experience, expertise, authoritative compliance, and trust. By focusing on these key aspects, industries can achieve optimal system performance, enhance safety, and improve operational efficiencies. Whether it's for industrial applications or everyday use, pressure regulators remain an indispensable tool in managing pressure effectively, ensuring seamless and trouble-free operation. For anyone involved in selecting and maintaining pressure regulators, staying informed with the latest technologies and best practices is vital for achieving sustainable and top-tier results.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024