1 月 . 20, 2025 09:08

Back to list

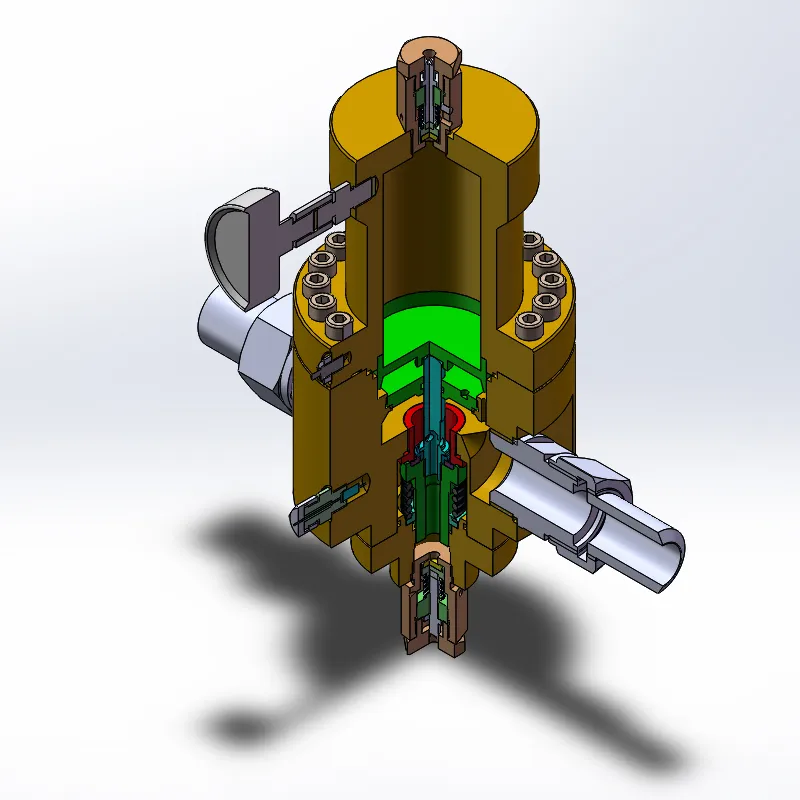

صمام منظم ضغط الغاز

Gas pressure regulators are essential components in ensuring the safe and efficient operation of gas systems in both residential and industrial settings. When discussing gas pressure regulators, particularly those that involve the phrase صمام منظم ضغط الغاز — or gas pressure regulating valve — we enter a domain that combines engineering precision, safety protocols, and user-friendly design.

Professionals engaged in manufacturing or selecting gas pressure regulators often emphasize the need for customization in design. This customization ensures compatibility with various gas types, such as natural gas, propane, or specialized industrial gases. Specialists utilize computational fluid dynamics (CFD) simulations during the design phase to optimize the flow paths within a regulator, allowing for greater accuracy and less pressure drop. Authoritativeness in choosing a gas pressure regulator is best demonstrated by adhering to international standards and certifications. Organizations such as the American National Standards Institute (ANSI) or the European Committee for Standardization (CEN) provide guidelines that ensure safety and performance benchmarks are achieved. A regulator meeting such standards is not only a testament to its quality but also a critical factor in risk management for businesses, protecting them from potential liabilities associated with equipment failure. Trustworthiness in the context of gas pressure regulators can be built through transparent transactions and reliable after-sales service. Manufacturers that provide detailed documentation, technical support, and accessible customer service often earn the trust of their consumers. Additionally, building trust is reinforced by offering warranties and maintenance services that assure clients of long-term support and reliability. In conclusion, the domain of gas pressure regulators, particularly under the key term صمام منظم ضغط الغاز, showcases a complex interplay of engineering and user-centric design. It draws on real-world experiences to highlight practical effectiveness, relies on expert knowledge to navigate the intricacies of gas flow management, upholds authoritative standards to ensure safety and reliability, and fosters trust through comprehensive service and support. As technology advances, so does the potential for smarter, more resilient gas pressure regulators, continuing the trend toward greater safety and efficiency in gas systems worldwide. By understanding these elements, both users and suppliers can make informed decisions that optimize performance and safety in their applications.

Professionals engaged in manufacturing or selecting gas pressure regulators often emphasize the need for customization in design. This customization ensures compatibility with various gas types, such as natural gas, propane, or specialized industrial gases. Specialists utilize computational fluid dynamics (CFD) simulations during the design phase to optimize the flow paths within a regulator, allowing for greater accuracy and less pressure drop. Authoritativeness in choosing a gas pressure regulator is best demonstrated by adhering to international standards and certifications. Organizations such as the American National Standards Institute (ANSI) or the European Committee for Standardization (CEN) provide guidelines that ensure safety and performance benchmarks are achieved. A regulator meeting such standards is not only a testament to its quality but also a critical factor in risk management for businesses, protecting them from potential liabilities associated with equipment failure. Trustworthiness in the context of gas pressure regulators can be built through transparent transactions and reliable after-sales service. Manufacturers that provide detailed documentation, technical support, and accessible customer service often earn the trust of their consumers. Additionally, building trust is reinforced by offering warranties and maintenance services that assure clients of long-term support and reliability. In conclusion, the domain of gas pressure regulators, particularly under the key term صمام منظم ضغط الغاز, showcases a complex interplay of engineering and user-centric design. It draws on real-world experiences to highlight practical effectiveness, relies on expert knowledge to navigate the intricacies of gas flow management, upholds authoritative standards to ensure safety and reliability, and fosters trust through comprehensive service and support. As technology advances, so does the potential for smarter, more resilient gas pressure regulators, continuing the trend toward greater safety and efficiency in gas systems worldwide. By understanding these elements, both users and suppliers can make informed decisions that optimize performance and safety in their applications.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024