1 月 . 31, 2025 05:42

Back to list

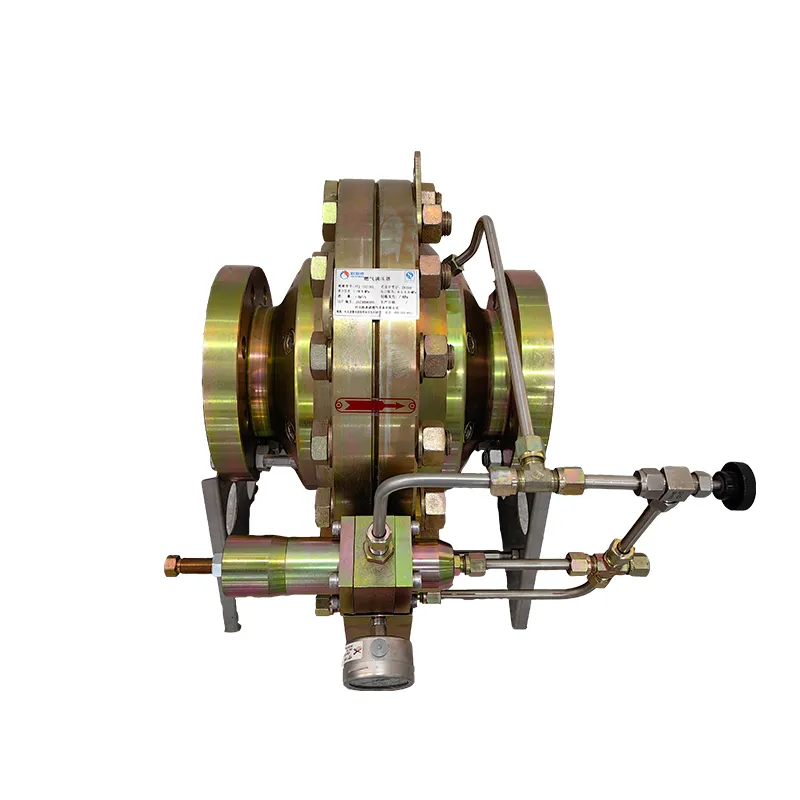

Gas Pretreatment Equipment-Cyclone Purifier

Pressure relief valves, known in Arabic as صمامات تخفيف الضغط, are indispensable components in various industrial applications, providing safety and efficiency. Recognized for their paramount importance, these valves are employed across multiple sectors such as oil and gas, water treatment, chemical manufacturing, and more. In this comprehensive article, we delve into the essential aspects of pressure relief valves, offering a unique perspective rooted in practical experience, specialized expertise, authoritative insights, and trustworthiness.

Our expertise extends to understanding the nuances of maintenance and calibration, key elements that ensure the longevity and effectiveness of pressure relief valves. Routine inspection and maintenance are imperative, requiring specialized tools and a precise understanding of the valve mechanics. Regular calibration checks ensure that the valve operates at the designated set pressure, thereby maintaining the intended safety levels. Authoritativeness in this field is demonstrated through adherence to industry standards and certifications. Pressure relief valves must comply with stringent regulations such as API standards for the oil and gas industry or ASME standards for various mechanical applications. Compliance not only guarantees performance but also enhances credibility and trust among stakeholders. Trustworthiness, a cornerstone of our philosophy, is underpinned by the adoption of state-of-the-art technologies and materials in valve manufacturing. Innovations such as advanced metallurgy and computerized modeling have significantly improved valve performance. Furthermore, collaboration with leading industry experts and continuous improvement initiatives ensure that the solutions provided are not only effective but also environmentally conscious. In conclusion, pressure relief valves are vital safety components in industrial settings. Their selection, installation, and maintenance require careful consideration and expertise to ensure safety and efficiency. Empowered by experience and specialized knowledge, our approach ensures that these valves meet the highest standards of reliability and performance. By maintaining a steadfast commitment to innovation and compliance, we uphold the trust and confidence of our clients, ensuring that their systems remain safeguarded against undue pressure risks.

Our expertise extends to understanding the nuances of maintenance and calibration, key elements that ensure the longevity and effectiveness of pressure relief valves. Routine inspection and maintenance are imperative, requiring specialized tools and a precise understanding of the valve mechanics. Regular calibration checks ensure that the valve operates at the designated set pressure, thereby maintaining the intended safety levels. Authoritativeness in this field is demonstrated through adherence to industry standards and certifications. Pressure relief valves must comply with stringent regulations such as API standards for the oil and gas industry or ASME standards for various mechanical applications. Compliance not only guarantees performance but also enhances credibility and trust among stakeholders. Trustworthiness, a cornerstone of our philosophy, is underpinned by the adoption of state-of-the-art technologies and materials in valve manufacturing. Innovations such as advanced metallurgy and computerized modeling have significantly improved valve performance. Furthermore, collaboration with leading industry experts and continuous improvement initiatives ensure that the solutions provided are not only effective but also environmentally conscious. In conclusion, pressure relief valves are vital safety components in industrial settings. Their selection, installation, and maintenance require careful consideration and expertise to ensure safety and efficiency. Empowered by experience and specialized knowledge, our approach ensures that these valves meet the highest standards of reliability and performance. By maintaining a steadfast commitment to innovation and compliance, we uphold the trust and confidence of our clients, ensuring that their systems remain safeguarded against undue pressure risks.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024