2 月 . 08, 2025 00:49

Back to list

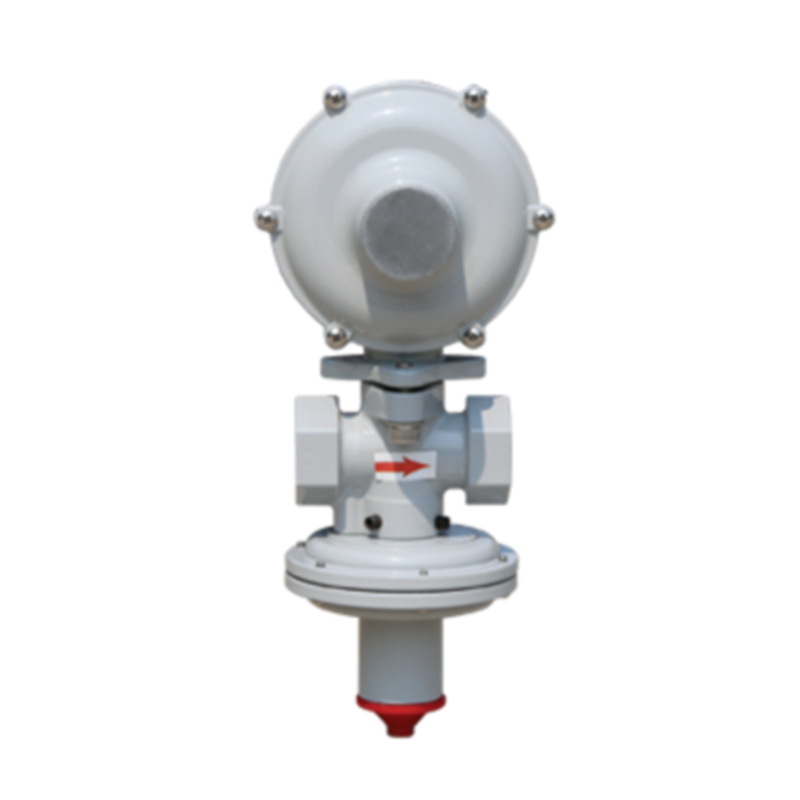

صمام التنفيس

In the ever-evolving world of industrial applications, the role of a pressure relief valve, known in Arabic as صمام التنفيس, is critical. These seemingly simple devices ensure the safety and efficiency of systems across numerous industries. Through decades of development and innovation, they have become indispensable components in environments where pressure control is paramount.

In HVAC systems, pressure relief valves manage the dynamic requirements of heating and cooling cycles. Here, they maintain refrigerant pressure within optimal limits, preventing system overloads that could lead to malfunctions or energy inefficiency. Consequently, these valves contribute significantly to the sustainability and environmental compliance of commercial and residential HVAC systems. When discussing صمام التنفيس, attention must also be directed toward their design innovations. Recent advancements have introduced smart valve systems that integrate with digital monitoring platforms. These smart systems utilize sensors and software to provide real-time data and predictive analytics, allowing for preventive maintenance and enhanced operational insights. Such innovations not only improve reliability and efficiency but also extend the lifespan of equipment through optimized performance. The authoritative role of organizations and standards bodies cannot be overlooked in the pressure relief valve domain. Standards such as those set by the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) guide the design, manufacturing, and testing of pressure relief valves. Compliance with these standards is a testament to a product's trustworthiness and quality, ensuring that it meets specific safety, reliability, and performance criteria. Choosing the right pressure relief valve is a decision that combines experience, expertise, and trustworthiness. It is crucial to assess the application requirements comprehensively, considering factors such as operating pressures, temperatures, flow rates, and media types. Consulting with industry experts and leveraging authoritative resources can lead to an informed choice, ensuring that the selected valve not only meets but exceeds safety and performance expectations. In conclusion, the pressure relief valve, or صمام التنفيس, remains a pillar of safety and efficiency across multiple industries. Its role in preserving the dynamic balance of pressure in complex systems is indispensable. As technology advances, the fusion of experience, expertise, authority, and trust will continue to drive innovations in pressure relief solutions, reinforcing their status as essential components in industrial applications worldwide.

In HVAC systems, pressure relief valves manage the dynamic requirements of heating and cooling cycles. Here, they maintain refrigerant pressure within optimal limits, preventing system overloads that could lead to malfunctions or energy inefficiency. Consequently, these valves contribute significantly to the sustainability and environmental compliance of commercial and residential HVAC systems. When discussing صمام التنفيس, attention must also be directed toward their design innovations. Recent advancements have introduced smart valve systems that integrate with digital monitoring platforms. These smart systems utilize sensors and software to provide real-time data and predictive analytics, allowing for preventive maintenance and enhanced operational insights. Such innovations not only improve reliability and efficiency but also extend the lifespan of equipment through optimized performance. The authoritative role of organizations and standards bodies cannot be overlooked in the pressure relief valve domain. Standards such as those set by the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) guide the design, manufacturing, and testing of pressure relief valves. Compliance with these standards is a testament to a product's trustworthiness and quality, ensuring that it meets specific safety, reliability, and performance criteria. Choosing the right pressure relief valve is a decision that combines experience, expertise, and trustworthiness. It is crucial to assess the application requirements comprehensively, considering factors such as operating pressures, temperatures, flow rates, and media types. Consulting with industry experts and leveraging authoritative resources can lead to an informed choice, ensuring that the selected valve not only meets but exceeds safety and performance expectations. In conclusion, the pressure relief valve, or صمام التنفيس, remains a pillar of safety and efficiency across multiple industries. Its role in preserving the dynamic balance of pressure in complex systems is indispensable. As technology advances, the fusion of experience, expertise, authority, and trust will continue to drive innovations in pressure relief solutions, reinforcing their status as essential components in industrial applications worldwide.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024