2 月 . 08, 2025 05:20

Back to list

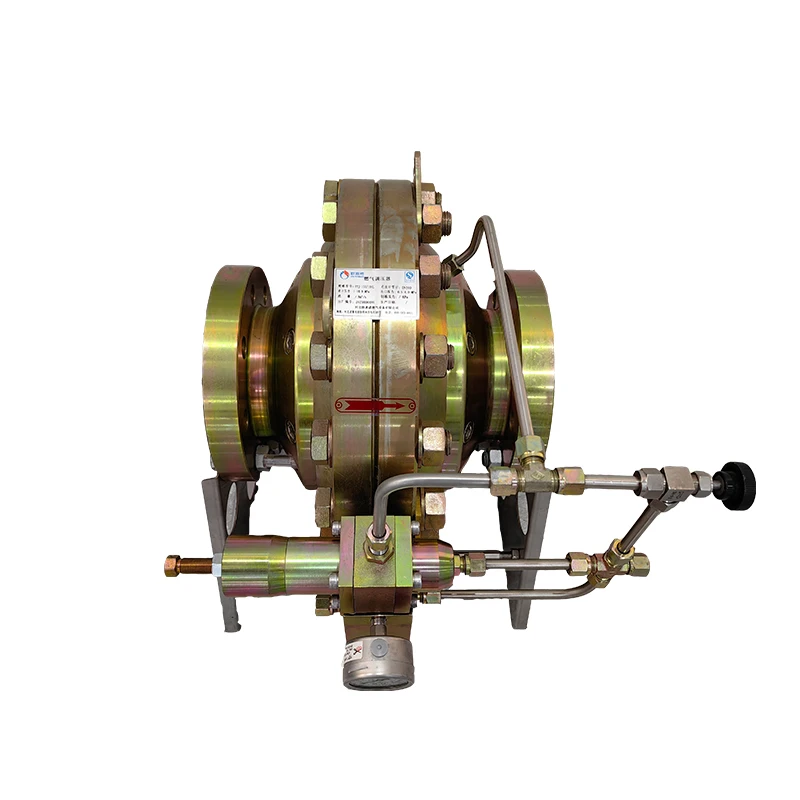

منظم ضغط الغاز

Understanding the importance of a gas pressure regulator is crucial for anyone dealing with gas systems, whether it's for domestic, industrial, or commercial use. A gas pressure regulator ensures that the gas coming from high-pressure containers is reduced to a predetermined and safe level necessary for downstream equipment, maintaining efficiency and safety across various applications.

From an authoritative perspective, industry standards and regulations play a pivotal role in determining the benchmarks for gas pressure regulators. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) have established guidelines that dictate the safety and performance requirements for these devices. Regulator manufacturers that adhere to these standards are more likely to produce reliable products, thereby enhancing credibility and trust in their offerings. Trustworthiness is particularly important in the realm of gas equipment. Customers and businesses must put their faith in these devices, as they can have significant safety implications. Several factors contribute to the perceived trustworthiness of a gas pressure regulator. These include the reputation of the manufacturer, the transparency of information regarding the product, and the availability of customer support and after-sales service. Moreover, testimonials and reviews from other users provide valuable insights into the product's real-world performance and reliability. In conclusion, gas pressure regulators are essential components that contribute to the safe and efficient operation of gas-powered systems. Their design and manufacturing must meet the highest standards of performance and safety. By aligning with established guidelines and standards, emphasizing expert opinions, and building trust through transparency and reliable customer service, manufacturers and suppliers can ensure that their customers experience the best in gas pressure management. When investing in a gas pressure regulator, considering these elements ensures not only the safety and efficiency of your operations but also the longevity and effectiveness of your equipment.

From an authoritative perspective, industry standards and regulations play a pivotal role in determining the benchmarks for gas pressure regulators. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) have established guidelines that dictate the safety and performance requirements for these devices. Regulator manufacturers that adhere to these standards are more likely to produce reliable products, thereby enhancing credibility and trust in their offerings. Trustworthiness is particularly important in the realm of gas equipment. Customers and businesses must put their faith in these devices, as they can have significant safety implications. Several factors contribute to the perceived trustworthiness of a gas pressure regulator. These include the reputation of the manufacturer, the transparency of information regarding the product, and the availability of customer support and after-sales service. Moreover, testimonials and reviews from other users provide valuable insights into the product's real-world performance and reliability. In conclusion, gas pressure regulators are essential components that contribute to the safe and efficient operation of gas-powered systems. Their design and manufacturing must meet the highest standards of performance and safety. By aligning with established guidelines and standards, emphasizing expert opinions, and building trust through transparency and reliable customer service, manufacturers and suppliers can ensure that their customers experience the best in gas pressure management. When investing in a gas pressure regulator, considering these elements ensures not only the safety and efficiency of your operations but also the longevity and effectiveness of your equipment.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024