2 月 . 13, 2025 11:47

Back to list

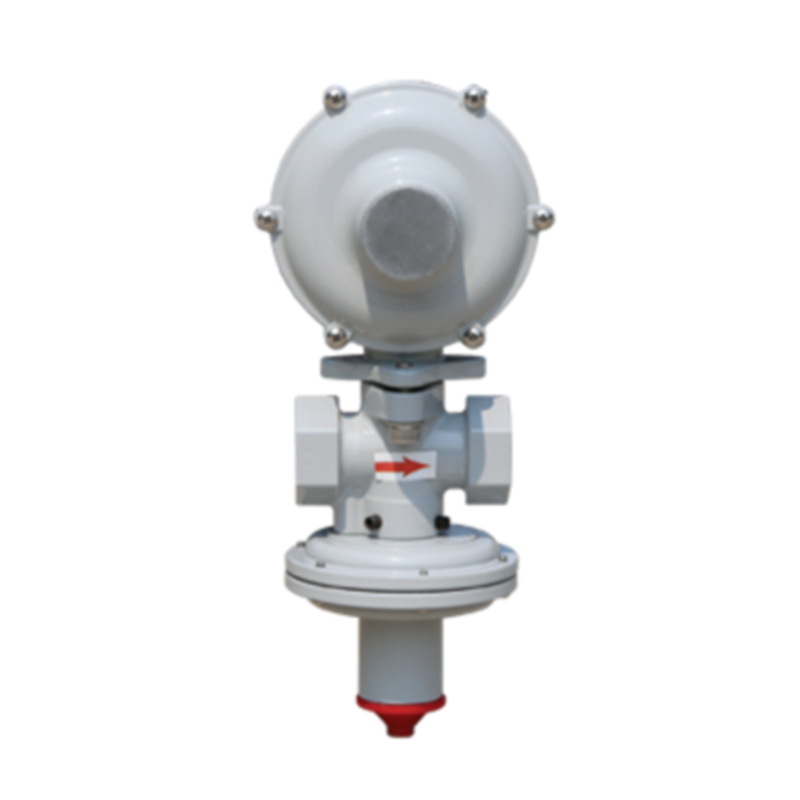

منظم الغاز

The gas regulator, often hailed as one of the unsung heroes in gas-utilizing environments, is quintessential for ensuring the safe and efficient use of propane or natural gas in various applications. Understanding its importance and functionality is vital for both domestic users and industrial personnel who prioritize safety and efficiency.

Consumers can benefit significantly from understanding the diversity within gas regulators. Adjustable versus preset regulators, single-stage versus two-stage models, and specific considerations for different types of gases all play roles in the selection of the appropriate regulator for any given situation. Adjustable models offer flexibility in scenarios where gas demand varies, while preset regulators provide simplicity and reliability for constant flow requirements. Prioritizing trust, reputable brands in the gas regulator market proactively seek certifications from recognized safety and compliance bodies. This not only verifies their product’s credibility but also demonstrates a commitment to consumer safety and satisfaction. Ensuring these certifications exist is a crucial step for buyers looking to invest in quality gas equipment. Finally, user experience is a crucial aspect of any product. Feedback loops between end-users and manufacturers are essential for continuous improvement. As users share their experiences with installations, issues, and performance, manufacturers can adapt designs to meet evolving needs. Open communication channels also promote transparency, fostering a broader understanding of gas regulator functionality among consumers, thereby enhancing their authoritative knowledge on the subject. In conclusion, gas regulators, while intricate, are foundational components in the safe utilization of gas systems. Their role in converting and stabilizing gas pressure is crucial across both domestic and industrial settings. By understanding their functionality and the expertise required in their utilization, consumers and professionals alike can appreciate the value these devices bring in fostering safe, efficient, and reliable environments.

Consumers can benefit significantly from understanding the diversity within gas regulators. Adjustable versus preset regulators, single-stage versus two-stage models, and specific considerations for different types of gases all play roles in the selection of the appropriate regulator for any given situation. Adjustable models offer flexibility in scenarios where gas demand varies, while preset regulators provide simplicity and reliability for constant flow requirements. Prioritizing trust, reputable brands in the gas regulator market proactively seek certifications from recognized safety and compliance bodies. This not only verifies their product’s credibility but also demonstrates a commitment to consumer safety and satisfaction. Ensuring these certifications exist is a crucial step for buyers looking to invest in quality gas equipment. Finally, user experience is a crucial aspect of any product. Feedback loops between end-users and manufacturers are essential for continuous improvement. As users share their experiences with installations, issues, and performance, manufacturers can adapt designs to meet evolving needs. Open communication channels also promote transparency, fostering a broader understanding of gas regulator functionality among consumers, thereby enhancing their authoritative knowledge on the subject. In conclusion, gas regulators, while intricate, are foundational components in the safe utilization of gas systems. Their role in converting and stabilizing gas pressure is crucial across both domestic and industrial settings. By understanding their functionality and the expertise required in their utilization, consumers and professionals alike can appreciate the value these devices bring in fostering safe, efficient, and reliable environments.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024