2 月 . 13, 2025 13:30

Back to list

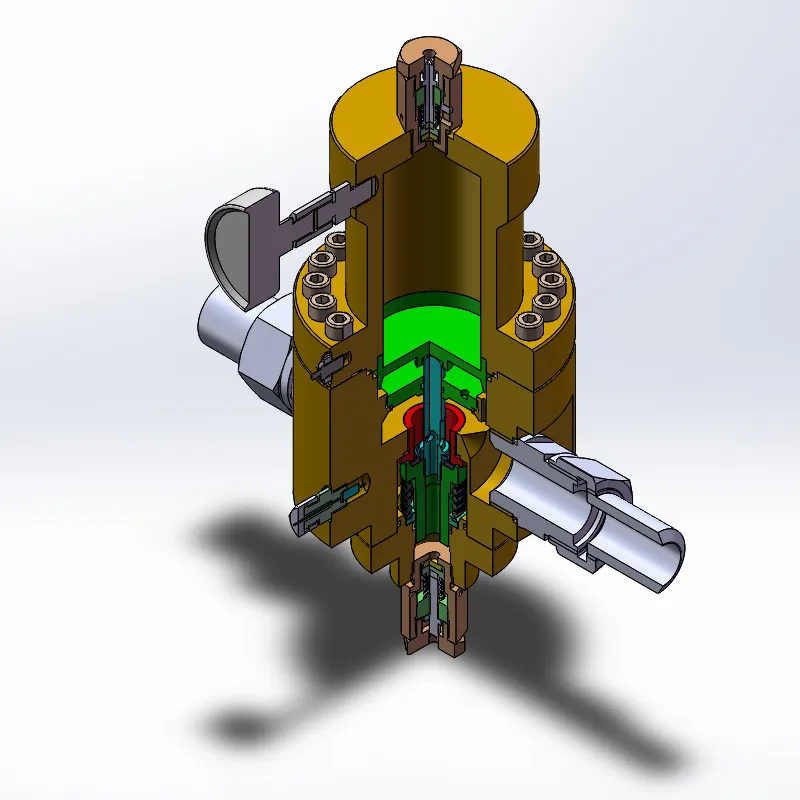

صمام هوائي

In the world of industrial automation and control systems, pneumatic valves, known in Arabic as [صمام هوائي], are indispensable components. These devices are critical for regulating the flow and pressure of gases and liquids in countless applications, reflecting both their expertise-driven design and authoritative presence across varied industries.

Trustworthiness in pneumatic valves is not just about performance reliability but also about safety. These valves are designed with fail-safes and precision controls to prevent undesirable incidents, securing operations in sensitive areas like pharmaceuticals and petrochemicals. This reputation for safety and reliability builds trust with consumers and stakeholders alike, who depend on these valves for uninterrupted and safe operations. In practice, maintaining pneumatic valves involves routine inspections and maintenance to ensure they function optimally. Experienced technicians focus on checking for wear and tear, ensuring air supply is clear of contaminants, and verifying that actuators and seals are in perfect condition. Such meticulous care prolongs the valve's life, minimizes downtime, and ensures continued compliance with industrial safety standards. By integrating these strategic insights and comprehensive checks, businesses not only optimize their operations but also achieve a significant competitive advantage. This demonstrates the critical role of pneumatic valves as both a product of high engineering expertise and a cornerstone of industrial trust. Overall, pneumatic valves [صمام هوائي] epitomize a blend of experience, expertise, authority, and trustworthiness, making them an essential component in efficient industrial systems. Their proven track record, empowered by technological advancements and stringent quality controls, continues to make them an unrivaled choice for industries worldwide, ensuring consistency and reliability in an ever-evolving industrial landscape.

Trustworthiness in pneumatic valves is not just about performance reliability but also about safety. These valves are designed with fail-safes and precision controls to prevent undesirable incidents, securing operations in sensitive areas like pharmaceuticals and petrochemicals. This reputation for safety and reliability builds trust with consumers and stakeholders alike, who depend on these valves for uninterrupted and safe operations. In practice, maintaining pneumatic valves involves routine inspections and maintenance to ensure they function optimally. Experienced technicians focus on checking for wear and tear, ensuring air supply is clear of contaminants, and verifying that actuators and seals are in perfect condition. Such meticulous care prolongs the valve's life, minimizes downtime, and ensures continued compliance with industrial safety standards. By integrating these strategic insights and comprehensive checks, businesses not only optimize their operations but also achieve a significant competitive advantage. This demonstrates the critical role of pneumatic valves as both a product of high engineering expertise and a cornerstone of industrial trust. Overall, pneumatic valves [صمام هوائي] epitomize a blend of experience, expertise, authority, and trustworthiness, making them an essential component in efficient industrial systems. Their proven track record, empowered by technological advancements and stringent quality controls, continues to make them an unrivaled choice for industries worldwide, ensuring consistency and reliability in an ever-evolving industrial landscape.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024