2 月 . 13, 2025 19:39

Back to list

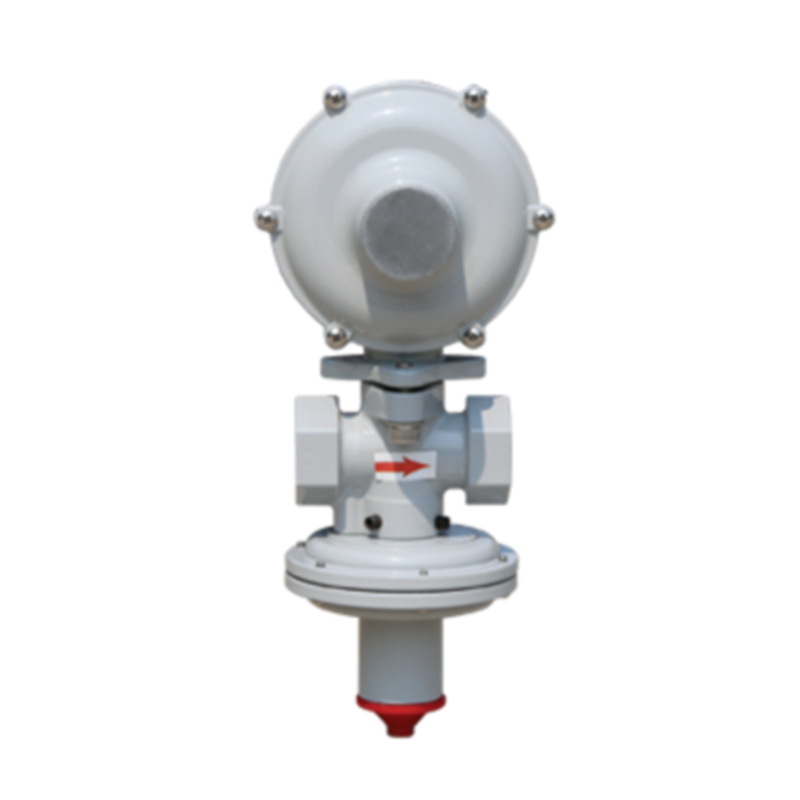

RTZB-15/0.2Medium Pressure Into Account Pressure Regulator

In industrial settings, the safety relief valve, commonly known as صمام تنفيس الأمان in Arabic, is indispensable for ensuring operational safety and efficiency. Engineered to maintain preset pressure levels by releasing excess pressure, these valves are crucial in preventing catastrophic equipment failures. The pivotal role they play makes it imperative to comprehend their functionality, application, and the nuances involved in their selection and maintenance, which aligns with Google's focus on Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

Maintenance and regular testing are critical components in establishing the trustworthiness of safety relief valves. Industry best practices recommend periodic inspections and testing to assess valve performance, ensuring they operate within their designed parameters. This includes checking for signs of wear, corrosion, or mechanical damage and calibrating the set pressure to avoid ‘nuisance trips’ where the valve opens unnecessarily, disrupting operations and potentially masking genuine pressure fluctuations. Furthermore, digital transformation has brought intelligent diagnostic tools into play, which enhance the trustworthiness of safety relief valves. These tools use sensors and IoT technology to monitor valve performance in real-time, predicting maintenance needs and potential failures before they occur, reducing downtime, and extending valve life. The E-E-A-T principle also suggests that sharing real-world case studies enhances understanding and promotes best practices. Take, for instance, the example of an oil refinery that incorporated cutting-edge safety relief valves equipped with smart sensors. By continuously monitoring real-time data and performing predictive analyses, the refinery reduced unscheduled downtimes by 20% and achieved substantial savings on maintenance costs. This exemplifies how hands-on experiences and technological advancements come together to improve safety and operational efficiency. In conclusion, the engineering marvel known as the safety relief valve is not merely a component but a vital guardian of industrial safety and efficiency. With increasing complexities in industrial processes, safety relief valves have risen to meet high expectations for performance and reliability. By prioritizing experience, expertise, and authoritative standards, coupled with maintaining trust through rigorous testing and real-time monitoring, industries can ensure that this critical equipment continues to safeguard lives and assets against unforeseen calamities.

Maintenance and regular testing are critical components in establishing the trustworthiness of safety relief valves. Industry best practices recommend periodic inspections and testing to assess valve performance, ensuring they operate within their designed parameters. This includes checking for signs of wear, corrosion, or mechanical damage and calibrating the set pressure to avoid ‘nuisance trips’ where the valve opens unnecessarily, disrupting operations and potentially masking genuine pressure fluctuations. Furthermore, digital transformation has brought intelligent diagnostic tools into play, which enhance the trustworthiness of safety relief valves. These tools use sensors and IoT technology to monitor valve performance in real-time, predicting maintenance needs and potential failures before they occur, reducing downtime, and extending valve life. The E-E-A-T principle also suggests that sharing real-world case studies enhances understanding and promotes best practices. Take, for instance, the example of an oil refinery that incorporated cutting-edge safety relief valves equipped with smart sensors. By continuously monitoring real-time data and performing predictive analyses, the refinery reduced unscheduled downtimes by 20% and achieved substantial savings on maintenance costs. This exemplifies how hands-on experiences and technological advancements come together to improve safety and operational efficiency. In conclusion, the engineering marvel known as the safety relief valve is not merely a component but a vital guardian of industrial safety and efficiency. With increasing complexities in industrial processes, safety relief valves have risen to meet high expectations for performance and reliability. By prioritizing experience, expertise, and authoritative standards, coupled with maintaining trust through rigorous testing and real-time monitoring, industries can ensure that this critical equipment continues to safeguard lives and assets against unforeseen calamities.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024