2 月 . 14, 2025 13:52

Back to list

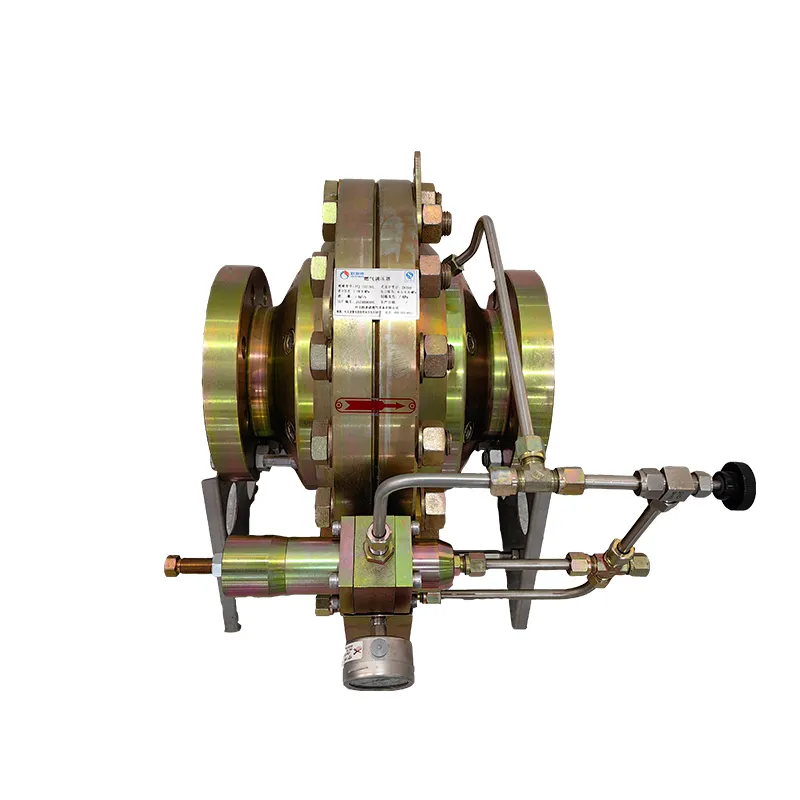

صمام تنفيس أمان الغاز

Gas Safety Relief Valves An Expert Review

Selecting the right gas safety relief valve requires a blend of technical knowledge and understanding of the application needs. Below are essential factors to consider 1. Pressure Rating It’s essential to choose a valve that matches or exceeds the maximum expected pressure of the system. This ensures that the valve will perform effectively during emergency conditions. 2. Flow Capacity The valve must be capable of handling the maximum flow that might be present in a fault condition. It’s crucial to perform detailed calculations based on the system's capacity and the nature of the gas to ensure proper sizing. 3. Material Durability Depending on the operational environment, the construction material can make a significant difference. For corrosive or high-temperature applications, valves made from stainless steel or other robust alloys are recommended. 4. Compliance and Standards Ensure that the chosen valve complies with local and international safety standards, such as ASME or ISO norms. This compliance not only guarantees safety but also ensures legal operation. Building Trust through Expertise Understanding the intricate details of gas safety relief valves demands comprehensive industry knowledge and professional expertise. As someone deeply entrenched in this field, I can affirm that the correct implementation of safety devices like these is non-negotiable. Operational efficiency, user safety, and legal compliance hinge on the right choice and maintenance of these valves. Implementing best practices, conducting regular maintenance checks, and keeping abreast of technological advancements form the cornerstone of a reliable safety system. Additionally, consulting with recognized professionals or engineers when designing or modifying systems can prevent costly mistakes. In conclusion, gas safety relief valves are pivotal components within any gas handling system. By recognizing their importance and understanding the factors that influence their selection and operation, businesses can ensure safer and more reliable operations. Recognizing the nuanced requirements of each application can help identify the most appropriate solution, ensuring that these vital components perform as expected when they're needed the most. In the realm of industrial safety, the value of expert advice and high-quality equipment cannot be overstated.

Selecting the right gas safety relief valve requires a blend of technical knowledge and understanding of the application needs. Below are essential factors to consider 1. Pressure Rating It’s essential to choose a valve that matches or exceeds the maximum expected pressure of the system. This ensures that the valve will perform effectively during emergency conditions. 2. Flow Capacity The valve must be capable of handling the maximum flow that might be present in a fault condition. It’s crucial to perform detailed calculations based on the system's capacity and the nature of the gas to ensure proper sizing. 3. Material Durability Depending on the operational environment, the construction material can make a significant difference. For corrosive or high-temperature applications, valves made from stainless steel or other robust alloys are recommended. 4. Compliance and Standards Ensure that the chosen valve complies with local and international safety standards, such as ASME or ISO norms. This compliance not only guarantees safety but also ensures legal operation. Building Trust through Expertise Understanding the intricate details of gas safety relief valves demands comprehensive industry knowledge and professional expertise. As someone deeply entrenched in this field, I can affirm that the correct implementation of safety devices like these is non-negotiable. Operational efficiency, user safety, and legal compliance hinge on the right choice and maintenance of these valves. Implementing best practices, conducting regular maintenance checks, and keeping abreast of technological advancements form the cornerstone of a reliable safety system. Additionally, consulting with recognized professionals or engineers when designing or modifying systems can prevent costly mistakes. In conclusion, gas safety relief valves are pivotal components within any gas handling system. By recognizing their importance and understanding the factors that influence their selection and operation, businesses can ensure safer and more reliable operations. Recognizing the nuanced requirements of each application can help identify the most appropriate solution, ensuring that these vital components perform as expected when they're needed the most. In the realm of industrial safety, the value of expert advice and high-quality equipment cannot be overstated.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024