2 月 . 14, 2025 17:44

Back to list

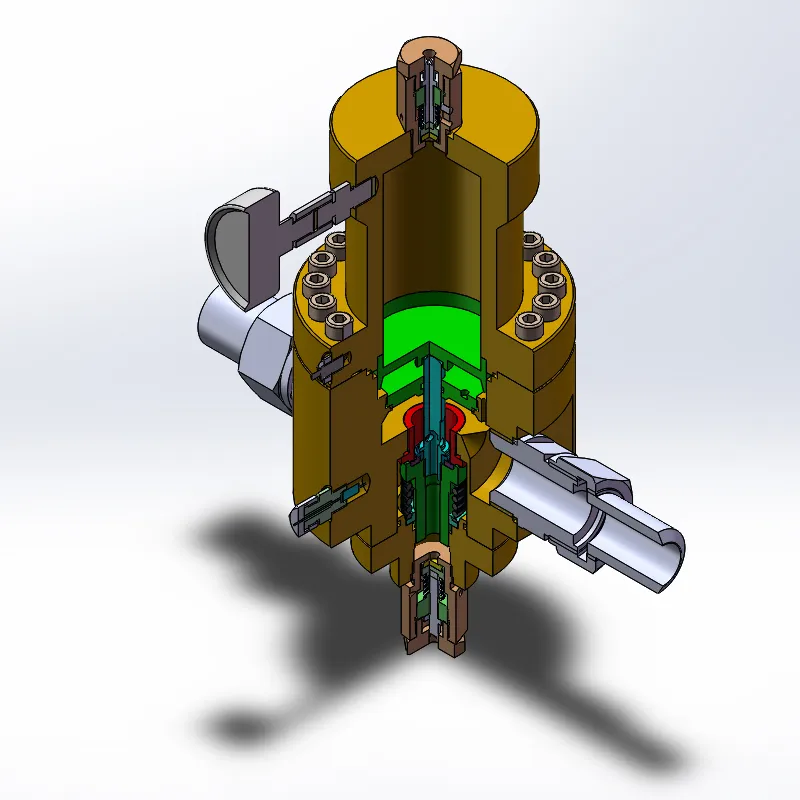

Gas Pretreatment Equipment-Cyclone Purifier

In the realm of industrial applications, a reliable pressure reducing valve (PRV) is essential for maintaining optimal operational efficiency and safety. The Arabic term مزلقة تخفيض الضغط directly refers to the critical function these devices perform. These valves mitigate the risks associated with overpressure situations by reducing the fluid pressure to a safe level, ensuring seamless operation across various systems. This article delves into the significance, functionality, and expert recommendations related to pressure reducing valves, offering insights grounded in real-world experience and authoritative expertise.

Innovations in valve technology continue to improve the reliability and functionality of pressure reducing valves. Advanced materials, smart technology integrations, and enhanced design have led to modern PRVs being more resilient and efficient than their predecessors. Such technological advancements support the overarching goal of reducing maintenance needs while optimizing performance. Incorporating IoT technology, for instance, allows for real-time monitoring and control, which can be pivotal in predictive maintenance strategies. From an authoritative standpoint, numerous industry bodies and standards govern the production and usage of PRVs, ensuring that they meet safety and performance benchmarks necessary for industrial applications. Compliance with these standards is non-negotiable; it assures users of the PRV’s credibility and reliability. International standards such as those from the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines that underpin best practices in PRV application and maintenance. Trustworthiness in the context of PRVs is predominantly rooted in the reputation of manufacturers and suppliers. Industry leaders attain this status through years of producing dependable products and providing unmatched customer service. They offer comprehensive warranties and dedicated after-sales support, underscoring their commitment to quality assurance. In conclusion, pressure reducing valves are crucial for the safe and efficient operation of various industrial systems. Their importance cannot be understated, and understanding their functionality, coupled with expertise in their application, ensures their optimal performance. As the industry progresses, staying abreast of technological advancements and abiding by established standards will continue to play an essential role in leveraging PRVs for maximum benefit. Prioritizing these aspects not only improves system reliability but also enhances safety and extends the lifespan of industrial equipment.

Innovations in valve technology continue to improve the reliability and functionality of pressure reducing valves. Advanced materials, smart technology integrations, and enhanced design have led to modern PRVs being more resilient and efficient than their predecessors. Such technological advancements support the overarching goal of reducing maintenance needs while optimizing performance. Incorporating IoT technology, for instance, allows for real-time monitoring and control, which can be pivotal in predictive maintenance strategies. From an authoritative standpoint, numerous industry bodies and standards govern the production and usage of PRVs, ensuring that they meet safety and performance benchmarks necessary for industrial applications. Compliance with these standards is non-negotiable; it assures users of the PRV’s credibility and reliability. International standards such as those from the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines that underpin best practices in PRV application and maintenance. Trustworthiness in the context of PRVs is predominantly rooted in the reputation of manufacturers and suppliers. Industry leaders attain this status through years of producing dependable products and providing unmatched customer service. They offer comprehensive warranties and dedicated after-sales support, underscoring their commitment to quality assurance. In conclusion, pressure reducing valves are crucial for the safe and efficient operation of various industrial systems. Their importance cannot be understated, and understanding their functionality, coupled with expertise in their application, ensures their optimal performance. As the industry progresses, staying abreast of technological advancements and abiding by established standards will continue to play an essential role in leveraging PRVs for maximum benefit. Prioritizing these aspects not only improves system reliability but also enhances safety and extends the lifespan of industrial equipment.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024