2 月 . 16, 2025 11:00

Back to list

Gas Pretreatment Equipment-Units of Pig Launcher and Receiver

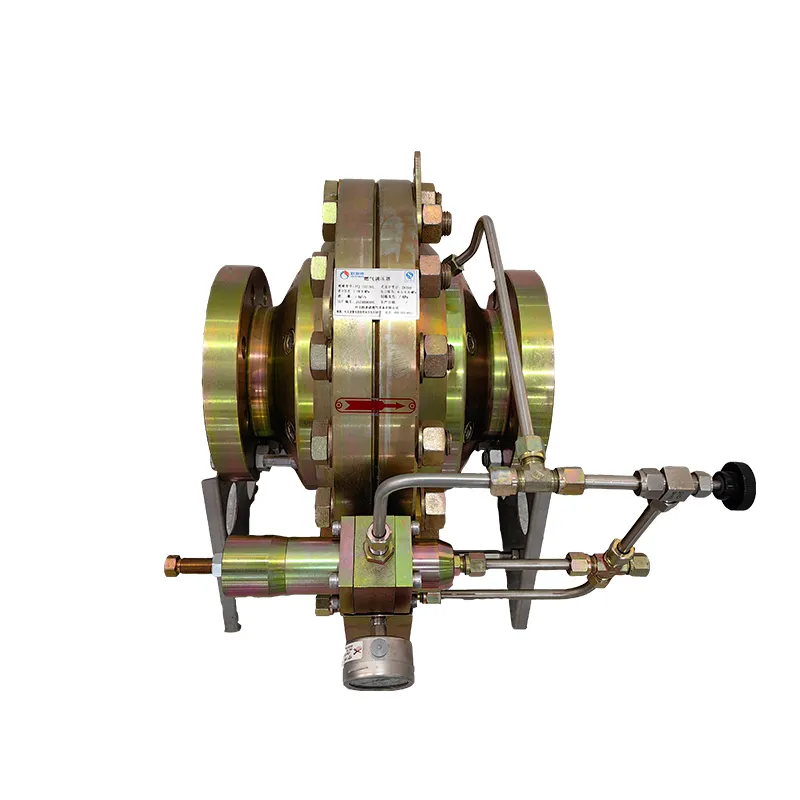

Understanding the Intricacies of Electric Valves A Comprehensive Guide

Safety is another fundamental aspect of electric valves. The implementation of advanced safety features, such as fail-safe mechanisms and manual overrides, ensures that the system remains secure even in the event of power failures or system malfunctions. This failsafe design not only protects the integrity of the process but also safeguards human operators and the environment from potential hazards. Despite their numerous advantages, the selection and implementation of electric valves require thorough consideration of various factors. Engineers must assess parameters such as pressure ratings, temperature ranges, and flow characteristics to ensure optimal performance. Furthermore, understanding the operational environment and maintenance requirements is crucial to prolong the lifespan of the valve and minimize operational downtime. In terms of maintenance, electric valves offer significant advantages over their mechanical counterparts. Their design allows for reduced wear and tear, resulting in lower maintenance costs and extended service life. Routine checks, including inspections of seals and actuators, combined with state-of-the-art diagnostic tools, can effectively preempt issues before they escalate, ensuring uninterrupted operation. Electric valves represent a paradigm shift in fluid and gas management, embodying efficiency, precision, and control. Their evolution reflects the advancements in industrial automation, moving towards more intelligent and interconnected systems. As technology progresses, the capabilities of electric valves will inevitably expand, offering even more specialized and efficient solutions. For professionals considering the integration of electric valves into their operations, choosing a reputable manufacturer is of paramount importance. A manufacturer with a proven track record and expertise can offer not only high-quality products but also invaluable support and advice tailored to specific needs. Collaborations with industry experts provide additional layers of insight and assurance, addressing the unique challenges posed by different applications. In conclusion, electric valves are a cornerstone of modern industrial systems, offering unparalleled control and efficiency. The continuous innovation and adaptability of these devices underscore their importance across diverse sectors. With a keen focus on expertise, authoritativeness, and trustworthiness, the adoption of electric valves ensures robust, reliable, and forward-thinking process management solutions.

Safety is another fundamental aspect of electric valves. The implementation of advanced safety features, such as fail-safe mechanisms and manual overrides, ensures that the system remains secure even in the event of power failures or system malfunctions. This failsafe design not only protects the integrity of the process but also safeguards human operators and the environment from potential hazards. Despite their numerous advantages, the selection and implementation of electric valves require thorough consideration of various factors. Engineers must assess parameters such as pressure ratings, temperature ranges, and flow characteristics to ensure optimal performance. Furthermore, understanding the operational environment and maintenance requirements is crucial to prolong the lifespan of the valve and minimize operational downtime. In terms of maintenance, electric valves offer significant advantages over their mechanical counterparts. Their design allows for reduced wear and tear, resulting in lower maintenance costs and extended service life. Routine checks, including inspections of seals and actuators, combined with state-of-the-art diagnostic tools, can effectively preempt issues before they escalate, ensuring uninterrupted operation. Electric valves represent a paradigm shift in fluid and gas management, embodying efficiency, precision, and control. Their evolution reflects the advancements in industrial automation, moving towards more intelligent and interconnected systems. As technology progresses, the capabilities of electric valves will inevitably expand, offering even more specialized and efficient solutions. For professionals considering the integration of electric valves into their operations, choosing a reputable manufacturer is of paramount importance. A manufacturer with a proven track record and expertise can offer not only high-quality products but also invaluable support and advice tailored to specific needs. Collaborations with industry experts provide additional layers of insight and assurance, addressing the unique challenges posed by different applications. In conclusion, electric valves are a cornerstone of modern industrial systems, offering unparalleled control and efficiency. The continuous innovation and adaptability of these devices underscore their importance across diverse sectors. With a keen focus on expertise, authoritativeness, and trustworthiness, the adoption of electric valves ensures robust, reliable, and forward-thinking process management solutions.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024