2 月 . 16, 2025 13:09

Back to list

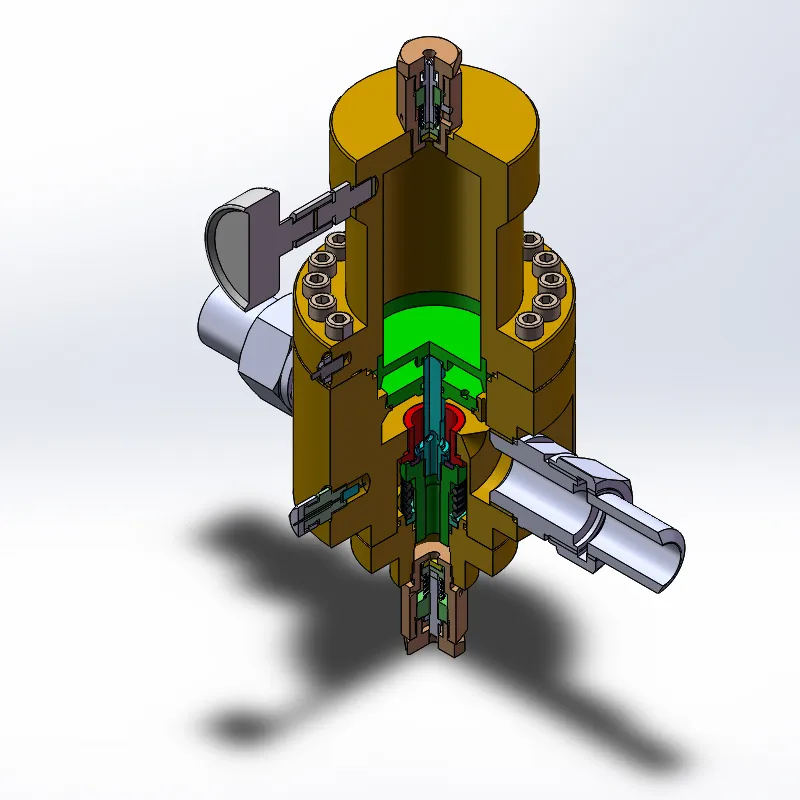

مرشح الغاز الطبيعي

Natural gas scrubbers are integral components in the energy and industrial sectors, fulfilling a critical role in ensuring efficient and reliable operations. With a focus on experience, expertise, authoritativeness, and trustworthiness (E-E-A-T), this article provides an in-depth exploration of natural gas scrubbers to highlight their significance in contemporary applications.

The authoritativeness of natural gas scrubber technology is evidenced by its adoption across a wide range of industries, including petrochemical, oil and gas, power generation, and manufacturing. Leading experts and industry standards emphasize the importance of regular maintenance and upgrades to meet evolving regulatory requirements. Certifications from recognized bodies such as the American Society of Mechanical Engineers (ASME) and compliance with international standards underscore the reliability and credibility of these technologies. Trustworthiness in the context of natural gas scrubbing is critical, not only from a safety and operational standpoint but also concerning environmental impact. As global attention turns toward reducing carbon footprints and minimizing environmental harm, scrubbers play a vital role in controlling emissions and ensuring that natural gas remains a cleaner alternative to other fossil fuels. Companies committed to sustainability invest in scrubber technologies that not only meet but exceed environmental standards, embodying corporate responsibility and public trust. In conclusion, natural gas scrubbers represent a convergence of experience, expertise, authoritativeness, and trustworthiness. Their application is not only technical but profoundly affects the operational excellence and environmental stewardship of industries worldwide. As technology evolves, so does the potential of natural gas scrubbers to facilitate more efficient, cleaner, and safer energy solutions, embodying the future of responsible industrial practices.

The authoritativeness of natural gas scrubber technology is evidenced by its adoption across a wide range of industries, including petrochemical, oil and gas, power generation, and manufacturing. Leading experts and industry standards emphasize the importance of regular maintenance and upgrades to meet evolving regulatory requirements. Certifications from recognized bodies such as the American Society of Mechanical Engineers (ASME) and compliance with international standards underscore the reliability and credibility of these technologies. Trustworthiness in the context of natural gas scrubbing is critical, not only from a safety and operational standpoint but also concerning environmental impact. As global attention turns toward reducing carbon footprints and minimizing environmental harm, scrubbers play a vital role in controlling emissions and ensuring that natural gas remains a cleaner alternative to other fossil fuels. Companies committed to sustainability invest in scrubber technologies that not only meet but exceed environmental standards, embodying corporate responsibility and public trust. In conclusion, natural gas scrubbers represent a convergence of experience, expertise, authoritativeness, and trustworthiness. Their application is not only technical but profoundly affects the operational excellence and environmental stewardship of industries worldwide. As technology evolves, so does the potential of natural gas scrubbers to facilitate more efficient, cleaner, and safer energy solutions, embodying the future of responsible industrial practices.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024