2 月 . 16, 2025 14:20

Back to list

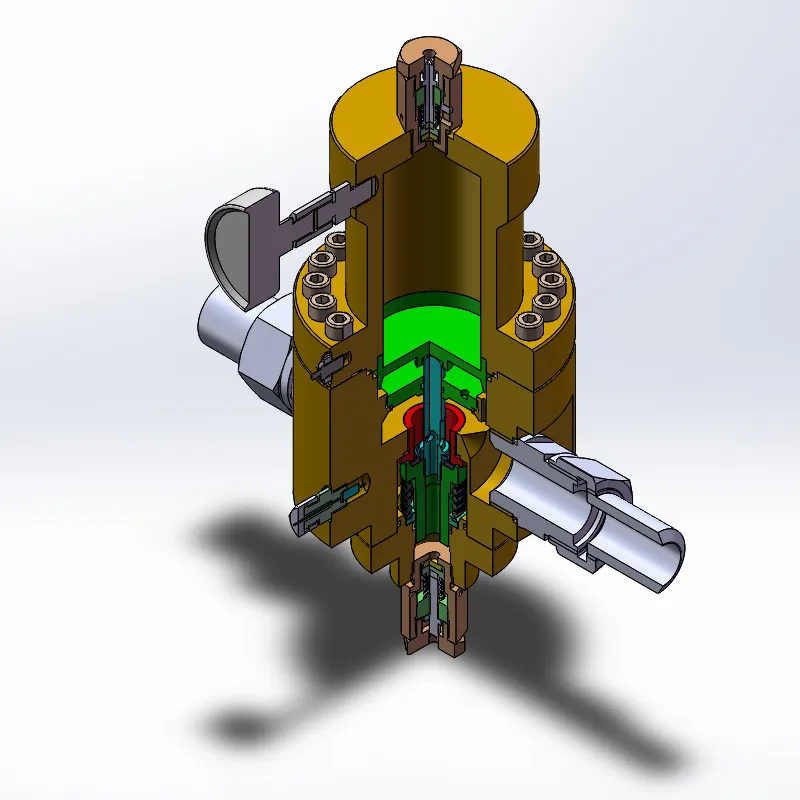

صمام تخفيض ضغط الغاز الطبيعي

Natural gas is an essential energy source that powers industries, homes, and vehicles around the world. However, the management of its pressure is a critical aspect to ensure safety and efficiency in its use and distribution. A natural gas pressure reduction valve (صمام تخفيض ضغط الغاز الطبيعي) plays a crucial role in this system by controlling the pressure levels and maintaining stability throughout the delivery network.

Authoritativeness in this field is evident through the endorsements and adoption of these valves by major industrial players. Renowned organizations rely on pressure reduction valves certified by international standards to ensure compliance with safety and environmental regulations. These certifications are a testament to the valve's capability in delivering consistent performance under various conditions, reinforcing their importance in maintaining operational integrity. Trustworthiness is enhanced through regular maintenance and expert handling of these valves. Routine inspections by certified professionals ensure that the valves operate within their designated parameters, averting potential system failures. Additionally, many manufacturers offer extensive warranty periods and customer support, assuring users of reliability and assistance when required. In product circles, technological advancements have facilitated the development of smart pressure reduction valves featuring real-time monitoring capabilities. Integrated with IoT technology, these valves provide live data and analytics to operators, allowing for predictive maintenance and immediate troubleshooting. This innovation not only improves operational efficiency but also enhances safety by preemptively identifying anomalies in the gas pressure network. In conclusion, natural gas pressure reduction valves are indispensable components that dictate the safety and efficiency of gas distribution networks. The combination of authentic user experience, specialized expertise, authoritative certifications, and robust trust mechanisms underscores the importance of investing in high-quality valves. These components safeguard the integrity of the natural gas infrastructure, ensuring that industries and households reap the benefits of this vital energy resource without compromising safety and operational performance. As technology progresses, the integration of intelligent systems into these valves offers an exciting prospect for further enhancing the reliability and efficiency of natural gas management.

Authoritativeness in this field is evident through the endorsements and adoption of these valves by major industrial players. Renowned organizations rely on pressure reduction valves certified by international standards to ensure compliance with safety and environmental regulations. These certifications are a testament to the valve's capability in delivering consistent performance under various conditions, reinforcing their importance in maintaining operational integrity. Trustworthiness is enhanced through regular maintenance and expert handling of these valves. Routine inspections by certified professionals ensure that the valves operate within their designated parameters, averting potential system failures. Additionally, many manufacturers offer extensive warranty periods and customer support, assuring users of reliability and assistance when required. In product circles, technological advancements have facilitated the development of smart pressure reduction valves featuring real-time monitoring capabilities. Integrated with IoT technology, these valves provide live data and analytics to operators, allowing for predictive maintenance and immediate troubleshooting. This innovation not only improves operational efficiency but also enhances safety by preemptively identifying anomalies in the gas pressure network. In conclusion, natural gas pressure reduction valves are indispensable components that dictate the safety and efficiency of gas distribution networks. The combination of authentic user experience, specialized expertise, authoritative certifications, and robust trust mechanisms underscores the importance of investing in high-quality valves. These components safeguard the integrity of the natural gas infrastructure, ensuring that industries and households reap the benefits of this vital energy resource without compromising safety and operational performance. As technology progresses, the integration of intelligent systems into these valves offers an exciting prospect for further enhancing the reliability and efficiency of natural gas management.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024