2 月 . 17, 2025 16:01

Back to list

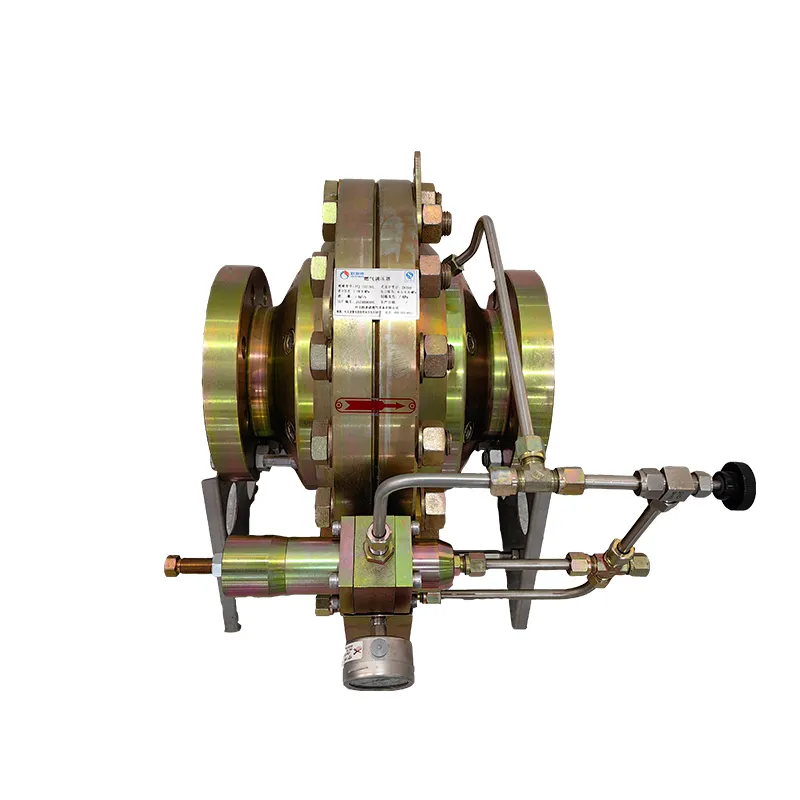

المبادل الحراري للغاز الطبيعي

Natural gas heat exchangers play a pivotal role in the energy sector, providing efficient heat transfer solutions crucial for various industrial applications. As someone deeply versed in the intricacies of heat transfer technologies, I understand their immense value in optimizing operational processes and improving energy efficiency.

The integration of modern technologies in the design and monitoring of heat exchangers has revolutionized the field. Advanced computational tools allow for precise simulations of heat transfer processes, helping engineers optimize designs before they are even constructed. Moreover, the advent of IoT technology has facilitated real-time monitoring of heat exchanger performance, allowing for proactive maintenance and minimizing downtime. Trust in these systems is built over time through consistent performance and reliability. With advanced engineering techniques and quality assurance protocols, manufacturers ensure that these heat exchangers meet rigorous industry standards. This commitment to excellence has positioned natural gas heat exchangers as a trusted component within industrial processes worldwide. In terms of authority, leading manufacturers and experts in the field of heat transfer provide a wealth of knowledge and innovation. Engagement in continuous research and development has driven advancements in this domain, ensuring that new designs are consistently more efficient than their predecessors. This authority is further solidified by compliance with international standards and certifications that guarantee product quality and performance. The experience of industries deploying these heat exchangers speaks volumes about their transformative potential. Industries ranging from petrochemicals to HVAC systems have reported significant enhancements in efficiency and cost savings. Furthermore, the adaptability of these exchangers to various processes without compromising on efficiency is a testament to their robust design and utility. In conclusion, natural gas heat exchangers are a critical component in the quest for energy efficiency and sustainability in industrial operations. Their expertly engineered designs, high-quality materials, and integration of modern technology make them indispensable in today's energy landscape. For industries aiming to optimize their processes and reduce their carbon footprint, investing in state-of-the-art natural gas heat exchangers is a strategic move backed by expertise and proven success stories.

The integration of modern technologies in the design and monitoring of heat exchangers has revolutionized the field. Advanced computational tools allow for precise simulations of heat transfer processes, helping engineers optimize designs before they are even constructed. Moreover, the advent of IoT technology has facilitated real-time monitoring of heat exchanger performance, allowing for proactive maintenance and minimizing downtime. Trust in these systems is built over time through consistent performance and reliability. With advanced engineering techniques and quality assurance protocols, manufacturers ensure that these heat exchangers meet rigorous industry standards. This commitment to excellence has positioned natural gas heat exchangers as a trusted component within industrial processes worldwide. In terms of authority, leading manufacturers and experts in the field of heat transfer provide a wealth of knowledge and innovation. Engagement in continuous research and development has driven advancements in this domain, ensuring that new designs are consistently more efficient than their predecessors. This authority is further solidified by compliance with international standards and certifications that guarantee product quality and performance. The experience of industries deploying these heat exchangers speaks volumes about their transformative potential. Industries ranging from petrochemicals to HVAC systems have reported significant enhancements in efficiency and cost savings. Furthermore, the adaptability of these exchangers to various processes without compromising on efficiency is a testament to their robust design and utility. In conclusion, natural gas heat exchangers are a critical component in the quest for energy efficiency and sustainability in industrial operations. Their expertly engineered designs, high-quality materials, and integration of modern technology make them indispensable in today's energy landscape. For industries aiming to optimize their processes and reduce their carbon footprint, investing in state-of-the-art natural gas heat exchangers is a strategic move backed by expertise and proven success stories.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024