2 月 . 17, 2025 18:25

Back to list

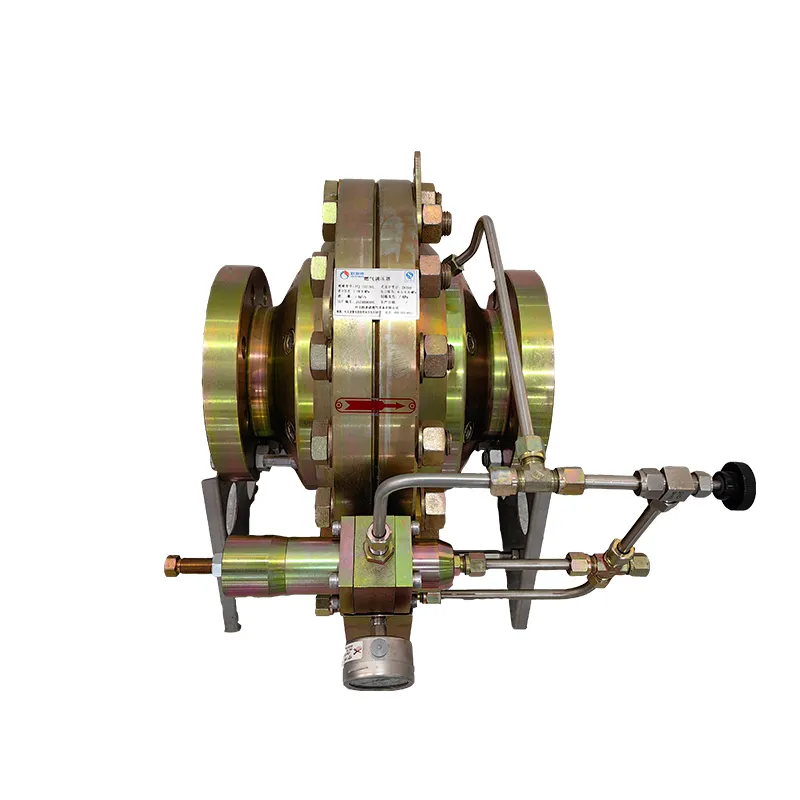

فلتر الغاز الغازي الغازي

In the vast world of natural gas exploration and extraction, one component stands out for its pivotal role in ensuring efficient and safe operations the gas filter. Known in Arabic as فلتر الغاز الغازي الغازي, this essential piece of equipment is critical for maintaining the purity and performance of gas systems, particularly in sectors demanding the highest standards of safety and efficiency such as the energy, industrial, and automotive industries.

The importance of gas filters is well-recognized by authoritative bodies across the globe, with standards and regulations set to ensure their optimal functioning. Compliance with these standards is non-negotiable, as it guarantees the safety of operations and the reliability of outcomes. Companies specializing in gas filtration systems continually invest in research and development to align with these standards, providing products that meet international guidelines and certifications. Trust is paramount in industries reliant on gas filtration systems. A dependable gas filter not only secures the confidence of operation managers but also safeguards the reputation of companies involved in the supply chain of natural gas. As such, manufacturers of gas filters often provide detailed specifications and testing results to verify their claims about filter efficiency and lifespan. Customers are encouraged to seek out brands that have a proven track record of dependability and robust customer support, which are critical indicators of trustworthiness. To sum up, the use of high-quality gas filters is indispensable in maintaining the integrity and efficiency of gas systems. Emphasizing expertise, manufacturers design these filters to endure the harshest conditions while delivering peak performance. With a strong foundation in field experience, a commitment to authoritative standards, and a reputation for trustworthiness, gas filters remain a cornerstone of the natural gas industry’s effort to provide cleaner, safer, and more efficient energy solutions to the world. Selecting the right gas filter is, therefore, a decision that carries significant implications for operational success and sustainability.

The importance of gas filters is well-recognized by authoritative bodies across the globe, with standards and regulations set to ensure their optimal functioning. Compliance with these standards is non-negotiable, as it guarantees the safety of operations and the reliability of outcomes. Companies specializing in gas filtration systems continually invest in research and development to align with these standards, providing products that meet international guidelines and certifications. Trust is paramount in industries reliant on gas filtration systems. A dependable gas filter not only secures the confidence of operation managers but also safeguards the reputation of companies involved in the supply chain of natural gas. As such, manufacturers of gas filters often provide detailed specifications and testing results to verify their claims about filter efficiency and lifespan. Customers are encouraged to seek out brands that have a proven track record of dependability and robust customer support, which are critical indicators of trustworthiness. To sum up, the use of high-quality gas filters is indispensable in maintaining the integrity and efficiency of gas systems. Emphasizing expertise, manufacturers design these filters to endure the harshest conditions while delivering peak performance. With a strong foundation in field experience, a commitment to authoritative standards, and a reputation for trustworthiness, gas filters remain a cornerstone of the natural gas industry’s effort to provide cleaner, safer, and more efficient energy solutions to the world. Selecting the right gas filter is, therefore, a decision that carries significant implications for operational success and sustainability.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024