3 月 . 04, 2025 08:56

Back to list

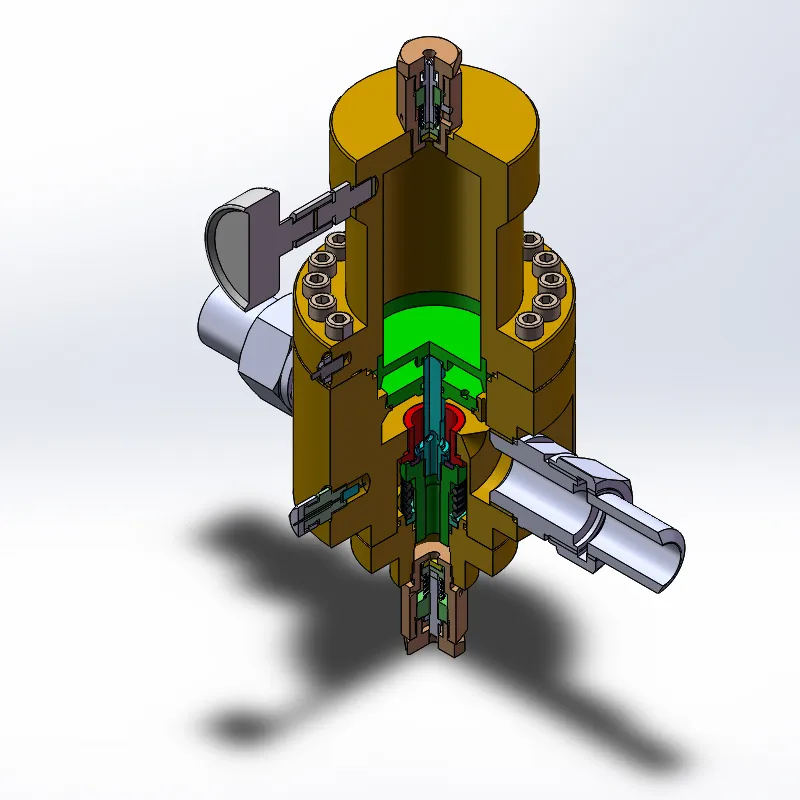

معدات التغويز

Gasification equipment, a revolutionary advancement in the field of energy conversion, stands as a testament to human ingenuity in addressing modern energy needs. By turning carbonaceous materials into synthetic gas (syngas), gasification systems offer unparalleled efficiency and sustainability. As an industry player with firsthand experience and deep expertise, understanding the multifaceted benefits and intricate technology behind gasification can position professionals as both authoritative and trustworthy voices in the energy sector.

Furthermore, gasification systems have been enhanced through continuous innovations, particularly in reactor design and material engineering, ensuring they remain at the forefront of modern energy solutions. The development of more robust and efficient catalysts, for instance, has enhanced the conversion rates and syngas purity, underscoring the importance of ongoing research and expertise in maintaining a competitive edge. For industry leaders, having a deep-rooted understanding of gasification extends beyond the technical aspects to include a strong grasp of market dynamics, regulatory landscapes, and sustainability goals. By fostering partnerships with leading research institutions and participating in international forums, these leaders solidify their status as authoritative voices capable of steering the sector towards broader adoption of gasification technologies. Prospective investors and stakeholders often view the credibility of a gasification project through the lens of past successes and expert endorsements. Trust is built not only on proven performance metrics but also on the transparent communication of potential risks and the strategies employed to mitigate them. Establishing robust safety protocols and maintaining compliance with global standards further reinforces the reliability and trustworthiness of gasification initiatives. In conclusion, gasification equipment represents a confluence of innovative technology, environmental stewardship, and economic opportunity. Mastery of this field entails a commitment to continuous learning, adaptation, and partnership with key industry players. By leading with experience, expertise, authority, and trust, stakeholders can effectively champion gasification technology as a cornerstone of the sustainable energy transition.

Furthermore, gasification systems have been enhanced through continuous innovations, particularly in reactor design and material engineering, ensuring they remain at the forefront of modern energy solutions. The development of more robust and efficient catalysts, for instance, has enhanced the conversion rates and syngas purity, underscoring the importance of ongoing research and expertise in maintaining a competitive edge. For industry leaders, having a deep-rooted understanding of gasification extends beyond the technical aspects to include a strong grasp of market dynamics, regulatory landscapes, and sustainability goals. By fostering partnerships with leading research institutions and participating in international forums, these leaders solidify their status as authoritative voices capable of steering the sector towards broader adoption of gasification technologies. Prospective investors and stakeholders often view the credibility of a gasification project through the lens of past successes and expert endorsements. Trust is built not only on proven performance metrics but also on the transparent communication of potential risks and the strategies employed to mitigate them. Establishing robust safety protocols and maintaining compliance with global standards further reinforces the reliability and trustworthiness of gasification initiatives. In conclusion, gasification equipment represents a confluence of innovative technology, environmental stewardship, and economic opportunity. Mastery of this field entails a commitment to continuous learning, adaptation, and partnership with key industry players. By leading with experience, expertise, authority, and trust, stakeholders can effectively champion gasification technology as a cornerstone of the sustainable energy transition.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024