3 月 . 06, 2025 14:10

Back to list

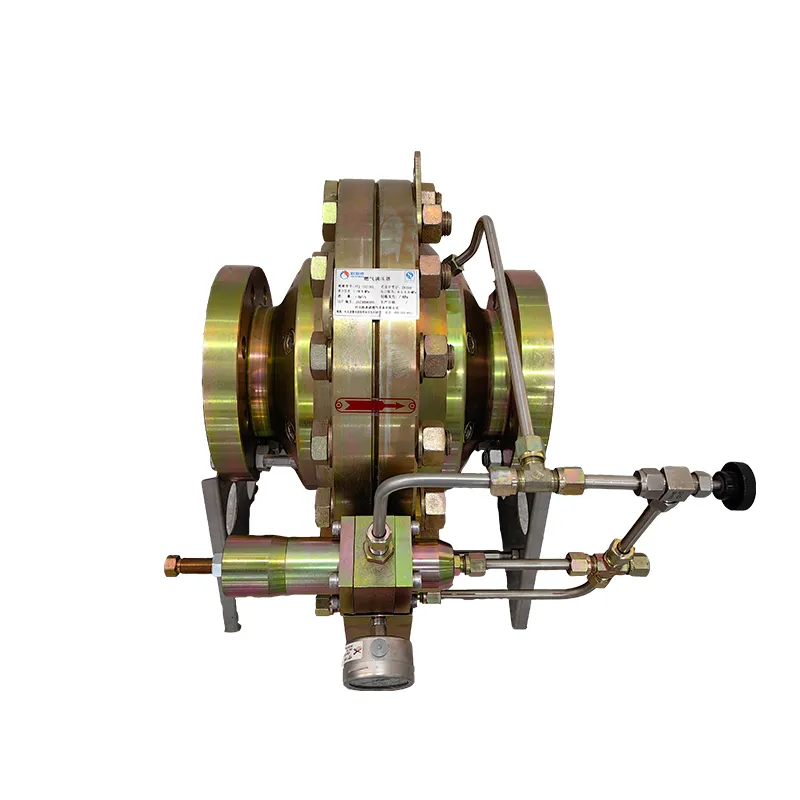

منظمات تخفيض الضغط

The necessity of pressure reducing valves in various industrial applications cannot be overstated. These devices, referred to in Arabic as منظمات تخفيض الضغط, are crucial in ensuring optimal performance and longevity of systems reliant on precise pressure management. Experience across multiple sectors has showcased the indispensable role these regulators play in streamlining operations.

Trustworthiness in valve performance is a vital criterion, and manufacturers often provide extensive testing records to affirm this. The tests simulate real-world conditions, ensuring that the valves are capable of withstanding extreme operational environments without fail. This level of trust is critical for industries seeking to maintain compliance with rigorous safety standards. Moreover, the discussion surrounding pressure reducing valves extends to innovations that enhance their efficiency. For instance, recent advancements have seen the integration of smart technology, enabling remote monitoring and adjustment. This not only improves the operators' capacity to manage pressure fluctuations efficiently but also enhances the safety and reliability of the entire system. As industries evolve, so too do the demands for more efficient, reliable, and durable pressure reducing valves. Awareness of these advancements and integrating them into existing systems can lead to significant improvements in energy savings and operational efficiencies. For industrial operators and engineers, staying abreast of these developments is crucial for maintaining competitiveness in the market. In conclusion, pressure reducing valves, or منظمات تخفيض الضغط, play a pivotal role in various industrial applications. Their ability to efficiently regulate pressure is a testament to the expertise and authority of the manufacturers. Ensuring trust in these devices through rigorous testing and quality assurance processes makes them an indispensable component in any industrial setting. With ongoing innovations and increasing reliance on smart technologies, the future of pressure reducing valves promises enhanced performance, safety, and reliability.

Trustworthiness in valve performance is a vital criterion, and manufacturers often provide extensive testing records to affirm this. The tests simulate real-world conditions, ensuring that the valves are capable of withstanding extreme operational environments without fail. This level of trust is critical for industries seeking to maintain compliance with rigorous safety standards. Moreover, the discussion surrounding pressure reducing valves extends to innovations that enhance their efficiency. For instance, recent advancements have seen the integration of smart technology, enabling remote monitoring and adjustment. This not only improves the operators' capacity to manage pressure fluctuations efficiently but also enhances the safety and reliability of the entire system. As industries evolve, so too do the demands for more efficient, reliable, and durable pressure reducing valves. Awareness of these advancements and integrating them into existing systems can lead to significant improvements in energy savings and operational efficiencies. For industrial operators and engineers, staying abreast of these developments is crucial for maintaining competitiveness in the market. In conclusion, pressure reducing valves, or منظمات تخفيض الضغط, play a pivotal role in various industrial applications. Their ability to efficiently regulate pressure is a testament to the expertise and authority of the manufacturers. Ensuring trust in these devices through rigorous testing and quality assurance processes makes them an indispensable component in any industrial setting. With ongoing innovations and increasing reliance on smart technologies, the future of pressure reducing valves promises enhanced performance, safety, and reliability.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024