5 月 . 29, 2025 10:19

Back to list

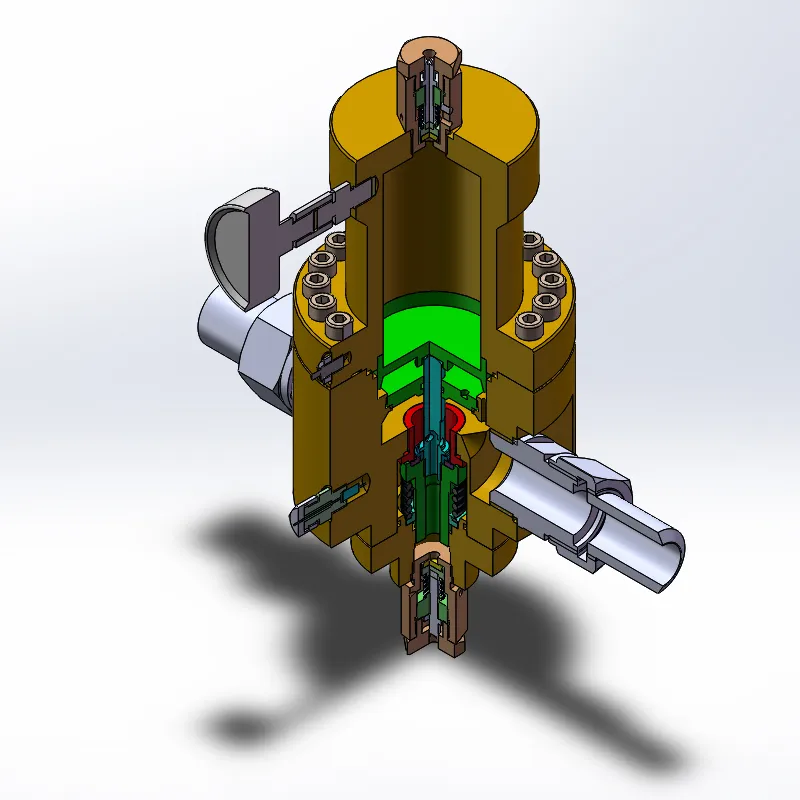

Cyclone Separator (فاصل الأعاصير) High-Efficiency Gas Filtration Solutions

- Introduction to Advanced Separation Technology in Gas Processing

- Technical Advantages of Modern Cyclonic Separators

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Diverse Industrial Requirements

- Case Study: Efficiency Improvement in Natural Gas Facilities

- Future Trends in Gas-Liquid Separation Systems

- Why فاصل الأعاصير

Remains Critical for Operational Excellence

(فاصل الأعاصير)

Introduction to Advanced Separation Technology in Gas Processing

In industrial gas processing, فاصل الأعاصير (cyclonic separators) and فاصل المرشح (filter separators) play a pivotal role in maintaining system integrity. These devices remove particulate matter and liquids from gas streams, ensuring operational efficiency. With the natural gas sector projected to grow at 4.2% CAGR through 2030, optimizing separation systems like فاصل مرشح الغاز الطبيعي (natural gas filter separators) has become a strategic priority for operators.

Technical Advantages of Modern Cyclonic Separators

Contemporary cyclonic separators achieve 99.8% efficiency in particle removal for particles ≥5μm, outperforming traditional filtration methods. Advanced computational fluid dynamics (CFD) designs enable 15-20% higher throughput while maintaining 0.05psi pressure drop specifications. Dual-stage systems combining centrifugal and gravitational separation demonstrate 40% longer maintenance intervals compared to single-stage units.

Performance Comparison: Leading Manufacturers in the Market

| Vendor | Efficiency (%) | Max Pressure (Bar) | Customization | MTBF (Hours) |

|---|---|---|---|---|

| Vendor A | 99.7 | 86 | Limited | 35,000 |

| Vendor B | 99.9 | 103 | Full | 42,500 |

| Vendor C | 99.5 | 64 | Modular | 28,000 |

Custom Solutions for Diverse Industrial Requirements

Modular separator configurations now support flow rates from 5,000 to 250,000 m³/h. Recent projects have implemented titanium-coated internals for sour gas applications, extending component lifespan by 300% in high-H₂S environments. Smart separators with IoT-enabled monitoring reduce unplanned downtime by 22% through predictive maintenance algorithms.

Case Study: Efficiency Improvement in Natural Gas Facilities

A Middle Eastern processing plant achieved 18% energy savings after upgrading to high-efficiency فاصل الأعاصير units. The installation of 12×40" cyclonic separators reduced particulate carryover to <0.01ppm, enabling compliance with ISO 13686:2020 gas quality standards. Operational data showed ROI within 14 months due to reduced filter replacement costs.

Future Trends in Gas-Liquid Separation Systems

Emerging technologies integrate nanotechnology membranes with cyclonic separation, demonstrating 99.95% efficiency in pilot tests. The market sees increasing adoption of composite materials that withstand temperatures up to 650°C, critical for LNG applications. Automated self-cleaning mechanisms are reducing manual intervention by 85% in offshore installations.

Why فاصل الأعاصير Remains Critical for Operational Excellence

As processing facilities face stricter environmental regulations, advanced فاصل مرشح الغاز الطبيعي systems provide both compliance and economic benefits. Operators report 30% reduction in emissions and 25% lower operating costs when implementing next-generation separation technologies. Continuous innovation ensures فاصل الأعاصیر solutions remain at the forefront of gas processing efficiency.

(فاصل الأعاصير)

FAQS on فاصل الأعاصير

Q: What is a Cyclone Separator and how does it work?

A: A cyclone separator uses centrifugal force to separate particles from gas or air. It’s commonly used in industries like mining and cement production. The design allows heavier particles to fall into a collection chamber while cleaner gas exits.

Q: What distinguishes a Cyclone Separator from a Filter Separator?

A: A cyclone separator relies on centrifugal force for separation, ideal for high particulate loads. A filter separator uses physical barriers like mesh or membranes for finer filtration. Both serve distinct roles in industrial processes.

Q: How often should a Natural Gas Filter Separator be maintained?

A: Maintenance depends on usage, but inspections every 3-6 months are typical. Check for clogs, corrosion, or pressure drops. Proper upkeep ensures efficient removal of contaminants from natural gas streams.

Q: Why is a Natural Gas Filter Separator critical in gas processing?

A: It removes impurities like dust, liquids, and solids from natural gas. This protects downstream equipment and ensures compliance with safety standards. Failure to filter can lead to pipeline damage or operational hazards.

Q: Can Cyclone Separators handle high-temperature applications?

A: Yes, cyclone separators are robust and can operate in high-temperature environments. They’re often used in power plants and refineries. Material choices like stainless steel enhance durability under extreme conditions.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024