2 月 . 11, 2025 16:14

Back to list

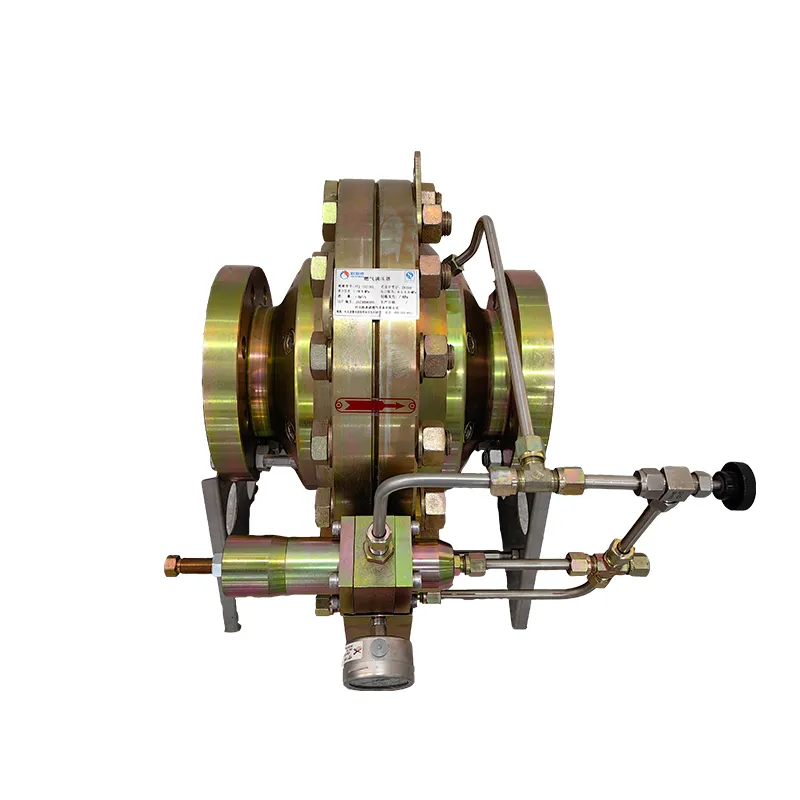

cyclone separator

Cyclone separators are essential components in various industrial applications, particularly when it comes to removing particulates from air and liquid streams without the use of filters or screens. These devices harness the power of centrifugal force to separate dust, dirt, and other particulates from fluids, making them invaluable in industries such as agriculture, manufacturing, and environmental management.

Experience shared by industry experts highlights that while cyclone separators are generally effective for particles larger than 10 micrometers, their performance can be enhanced with the addition of secondary measures for finer particulates. For example, pairing a cyclone separator with a bag filter or an electrostatic precipitator can achieve even higher levels of air or fluid purity, ensuring compliance with stringent environmental regulations. Trustworthiness in the use of cyclone separators is reinforced by their widespread adoption and success stories across various sectors. For instance, many agricultural facilities have reported drastic improvements in air quality by integrating cyclone separators into their systems to manage dust particles generated during grain processing. Similarly, wood processing plants find cyclone separators indispensable not just for managing sawdust and chips but also for minimizing fire hazards. For those considering the implementation of cyclone separators, working with reputable manufacturers who offer customization options based on specific operational needs is critical. These manufacturers often have a proven track record of delivering systems that balance efficiency, durability, and cost-effectiveness, ensuring that the investment translates into tangible operational improvements. In conclusion, cyclone separators represent a combination of simplicity and efficiency in handling large streams of particulate-laden fluids. Their role in improving air and fluid quality, safeguarding machinery, and reducing maintenance costs underscores their importance across multiple industries. Trust in their performance stems from a solid foundation of expertise and real-world application success, making them a reliable choice for companies looking to optimize their particulate management processes.

Experience shared by industry experts highlights that while cyclone separators are generally effective for particles larger than 10 micrometers, their performance can be enhanced with the addition of secondary measures for finer particulates. For example, pairing a cyclone separator with a bag filter or an electrostatic precipitator can achieve even higher levels of air or fluid purity, ensuring compliance with stringent environmental regulations. Trustworthiness in the use of cyclone separators is reinforced by their widespread adoption and success stories across various sectors. For instance, many agricultural facilities have reported drastic improvements in air quality by integrating cyclone separators into their systems to manage dust particles generated during grain processing. Similarly, wood processing plants find cyclone separators indispensable not just for managing sawdust and chips but also for minimizing fire hazards. For those considering the implementation of cyclone separators, working with reputable manufacturers who offer customization options based on specific operational needs is critical. These manufacturers often have a proven track record of delivering systems that balance efficiency, durability, and cost-effectiveness, ensuring that the investment translates into tangible operational improvements. In conclusion, cyclone separators represent a combination of simplicity and efficiency in handling large streams of particulate-laden fluids. Their role in improving air and fluid quality, safeguarding machinery, and reducing maintenance costs underscores their importance across multiple industries. Trust in their performance stems from a solid foundation of expertise and real-world application success, making them a reliable choice for companies looking to optimize their particulate management processes.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024