1 月 . 26, 2025 03:58

Back to list

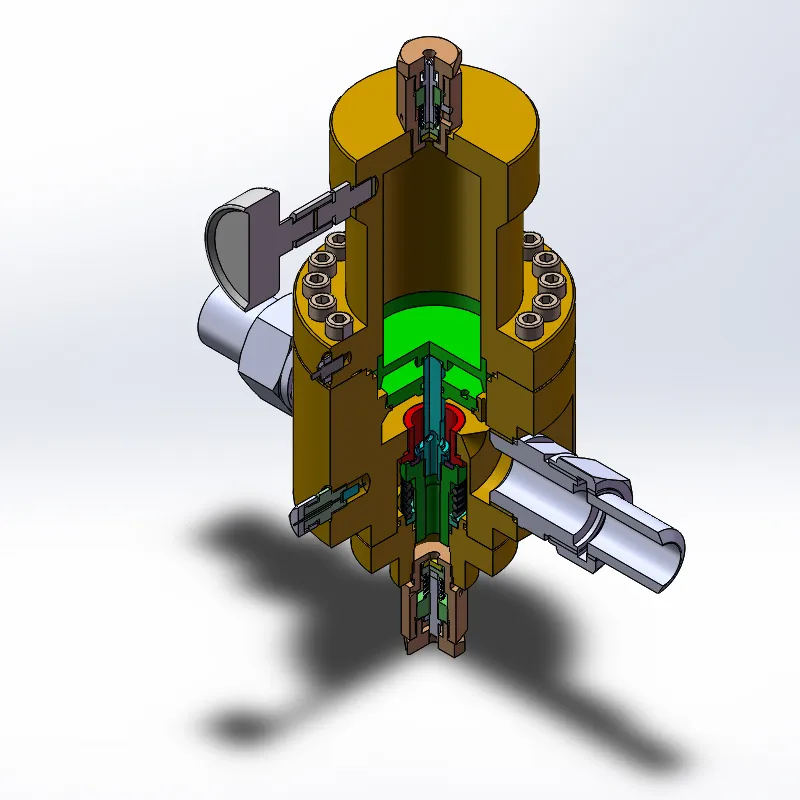

electric regulating valve

Electric regulating valves are pivotal in modern fluid control systems across various industries. These devices are integral for precision control, enabling efficient management of fluid flow, pressure, and temperature across complex systems. With unparalleled precision, electric regulating valves provide enhancements in operational efficiency and energy savings, making them indispensable for industries like chemical processing, HVAC systems, power generation, and more.

The authoritative nature of electric regulating valves is evidenced by their crucial role in critical applications. In the power generation sector, for instance, the ability of these valves to regulate steam flow precisely ensures that turbines operate at optimal efficiency, directly affecting power output and plant reliability. The precision and reliability of electric regulating valves also make them central to the pharmaceutical industry, where maintaining precise environmental conditions and process parameters is vital for product efficacy and safety. Trustworthiness in electric regulating valve performance is reinforced by comprehensive industry standards and rigorous testing protocols. Leading manufacturers adhere to ISO and ASME standards, ensuring that their products meet stringent quality and safety criteria. This compliance not only enhances the reliability and safety of these devices but also builds confidence among users who rely on them for critical operations. Additionally, customer testimonials often highlight the dependability of these valves, further solidifying their reputation as trustworthy components in fluid control systems. To sum up, electric regulating valves are essential tools that combine experience, expertise, authority, and trust, making them reliable components in various industrial applications. Their ability to deliver precision, durability, and efficiency positions them as strategic assets in optimizing modern fluid management systems. Facing ever-evolving industrial challenges, electric regulating valves will continue to adapt and provide innovative solutions to meet the demands of tomorrow's fluid control systems.

The authoritative nature of electric regulating valves is evidenced by their crucial role in critical applications. In the power generation sector, for instance, the ability of these valves to regulate steam flow precisely ensures that turbines operate at optimal efficiency, directly affecting power output and plant reliability. The precision and reliability of electric regulating valves also make them central to the pharmaceutical industry, where maintaining precise environmental conditions and process parameters is vital for product efficacy and safety. Trustworthiness in electric regulating valve performance is reinforced by comprehensive industry standards and rigorous testing protocols. Leading manufacturers adhere to ISO and ASME standards, ensuring that their products meet stringent quality and safety criteria. This compliance not only enhances the reliability and safety of these devices but also builds confidence among users who rely on them for critical operations. Additionally, customer testimonials often highlight the dependability of these valves, further solidifying their reputation as trustworthy components in fluid control systems. To sum up, electric regulating valves are essential tools that combine experience, expertise, authority, and trust, making them reliable components in various industrial applications. Their ability to deliver precision, durability, and efficiency positions them as strategic assets in optimizing modern fluid management systems. Facing ever-evolving industrial challenges, electric regulating valves will continue to adapt and provide innovative solutions to meet the demands of tomorrow's fluid control systems.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024