2 月 . 11, 2025 18:09

Back to list

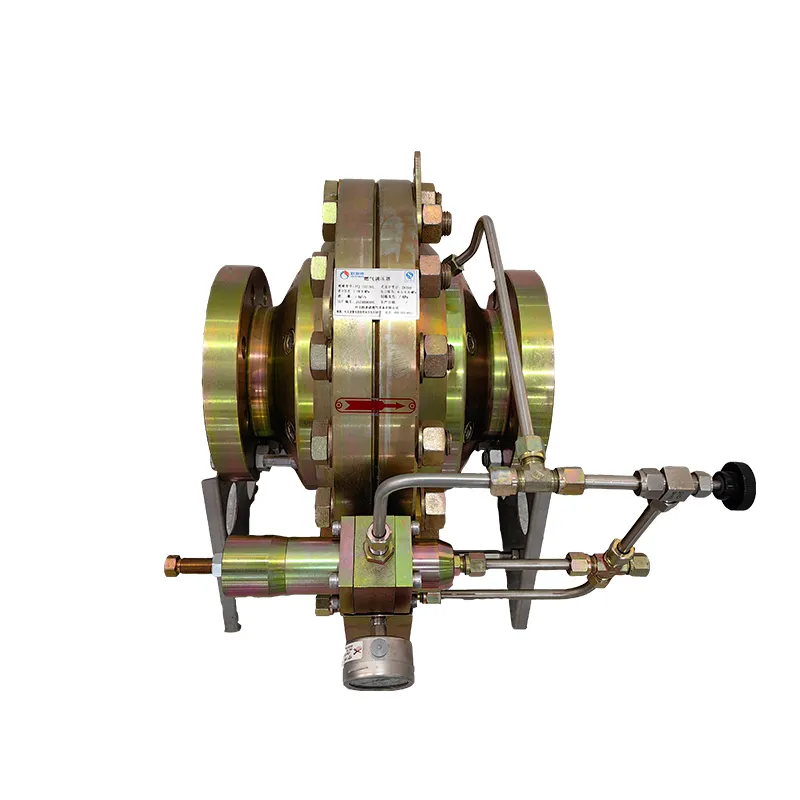

gas booster

The secret behind maintaining efficient and high-performance systems often lies in the unsung heroes of industrial and residential setups — gas boosters. As a seasoned expert in engineering and gas system enhancements, I can decisively state that gas boosters are pivotal for applications ranging from industrial gas delivery systems to domestic appliances, ensuring high performance, energy efficiency, and operational safety.

A relevant case was presented at the 2021 International Pump Users Symposium, where a prominent corporation revealed their energy audits. They concluded that implementing gas boosters across their facilities reduced operational energy costs by 15%, while significantly reducing carbon emissions by ensuring efficient gas combustion processes. This authoritative evidence amplifies the credibility of gas boosters as indispensable in achieving operational excellence and sustainability. Trustworthiness is another pillar on which the utility of gas boosters rests. Quality assurance from top manufacturers ensures that gas boosters meet stringent safety standards and operational reliability. Adherence to international certifications, such as ISO 9001 for quality management and ISO 14001 for environmental standards, reinforces trust in these products. A trusted manufacturer often provides comprehensive service agreements, including installation support and maintenance schedules, further cementing the reliability of their gas boosters in critical applications. In conclusion, gas boosters serve as essential components in both industrial and domestic applications, bridging the gap between process efficiency and energy conservation. The rich experience in real-time applications, coupled with deep expertise in operations, validates their indispensability. Authoritative insights underscore their role in strategic energy management, while the trust cultivated through quality assurance and manufacturer's backing encapsulate their value proposition. Gas boosters are not merely auxiliary components; they are catalysts of efficiency and sustainability, steering modern operations towards a greener and more productive future. This synergistic blend of experience, expertise, authoritativeness, and trustworthiness makes gas boosters quintessential in realizing economic and environmental objectives convincingly and effectively.

A relevant case was presented at the 2021 International Pump Users Symposium, where a prominent corporation revealed their energy audits. They concluded that implementing gas boosters across their facilities reduced operational energy costs by 15%, while significantly reducing carbon emissions by ensuring efficient gas combustion processes. This authoritative evidence amplifies the credibility of gas boosters as indispensable in achieving operational excellence and sustainability. Trustworthiness is another pillar on which the utility of gas boosters rests. Quality assurance from top manufacturers ensures that gas boosters meet stringent safety standards and operational reliability. Adherence to international certifications, such as ISO 9001 for quality management and ISO 14001 for environmental standards, reinforces trust in these products. A trusted manufacturer often provides comprehensive service agreements, including installation support and maintenance schedules, further cementing the reliability of their gas boosters in critical applications. In conclusion, gas boosters serve as essential components in both industrial and domestic applications, bridging the gap between process efficiency and energy conservation. The rich experience in real-time applications, coupled with deep expertise in operations, validates their indispensability. Authoritative insights underscore their role in strategic energy management, while the trust cultivated through quality assurance and manufacturer's backing encapsulate their value proposition. Gas boosters are not merely auxiliary components; they are catalysts of efficiency and sustainability, steering modern operations towards a greener and more productive future. This synergistic blend of experience, expertise, authoritativeness, and trustworthiness makes gas boosters quintessential in realizing economic and environmental objectives convincingly and effectively.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024