2 月 . 19, 2025 07:36

Back to list

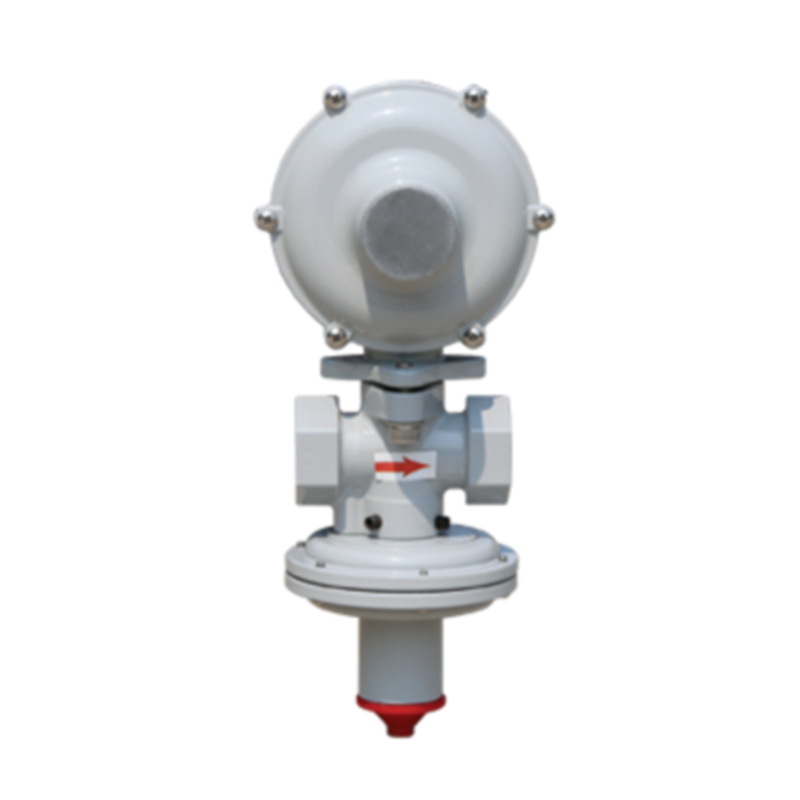

gas coalescer

Gas coalescers are essential components in various industrial applications where the purity of gas streams is crucial. Industries ranging from petrochemicals to natural gas processing rely on efficient coalescing technology to enhance product quality, ensure operational safety, and comply with environmental regulations. By capturing liquid droplets and particles, a gas coalescer increases system performance, prolongs equipment life, and minimizes maintenance downtime.

In navigating the complexities of gas coalescer integration, experience is indispensable. Field engineers who have spent years in the trenches provide valuable insights into troubleshooting and optimizing coalescer performance. Real-world scenarios often present unexpected challenges such as pressure drops and variable contaminant loads, where practical experience is critical for swift resolution. These seasoned professionals not only enhance operational reliability but also mentor less experienced colleagues, perpetuating a culture of excellence and safety. Another critical aspect of coalescer usage is maintenance. Scheduled upkeep and timely replacement are fundamental to sustaining performance over the unit's lifespan. Experts recommend regular inspection protocols and thorough cleaning procedures tailored to the specific coalescer type and application conditions. A well-maintained coalescer not only ensures gas purity but also prevents system failures and costly downtime. For businesses seeking to optimize their gas processing capabilities, partnering with knowledgeable coalescer manufacturers provides a competitive edge. Skilled product specialists collaborate closely with clients, offering technical support and strategic insights tailored to each application's unique needs. By fostering long-term relationships built on trust and performance, these partnerships drive innovation and success in the industry. In conclusion, gas coalescers stand as integral components in modern industrial processes, transforming gas streams into high-quality outputs. The synergy of experience, expertise, authority, and trustworthiness in coalescer technology drives efficiency and safety across sectors. As the industry evolves, the continuous pursuit of innovative solutions will sustain the essential balance between operational demands and environmental stewardship.

In navigating the complexities of gas coalescer integration, experience is indispensable. Field engineers who have spent years in the trenches provide valuable insights into troubleshooting and optimizing coalescer performance. Real-world scenarios often present unexpected challenges such as pressure drops and variable contaminant loads, where practical experience is critical for swift resolution. These seasoned professionals not only enhance operational reliability but also mentor less experienced colleagues, perpetuating a culture of excellence and safety. Another critical aspect of coalescer usage is maintenance. Scheduled upkeep and timely replacement are fundamental to sustaining performance over the unit's lifespan. Experts recommend regular inspection protocols and thorough cleaning procedures tailored to the specific coalescer type and application conditions. A well-maintained coalescer not only ensures gas purity but also prevents system failures and costly downtime. For businesses seeking to optimize their gas processing capabilities, partnering with knowledgeable coalescer manufacturers provides a competitive edge. Skilled product specialists collaborate closely with clients, offering technical support and strategic insights tailored to each application's unique needs. By fostering long-term relationships built on trust and performance, these partnerships drive innovation and success in the industry. In conclusion, gas coalescers stand as integral components in modern industrial processes, transforming gas streams into high-quality outputs. The synergy of experience, expertise, authority, and trustworthiness in coalescer technology drives efficiency and safety across sectors. As the industry evolves, the continuous pursuit of innovative solutions will sustain the essential balance between operational demands and environmental stewardship.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024