2 月 . 16, 2025 00:46

Back to list

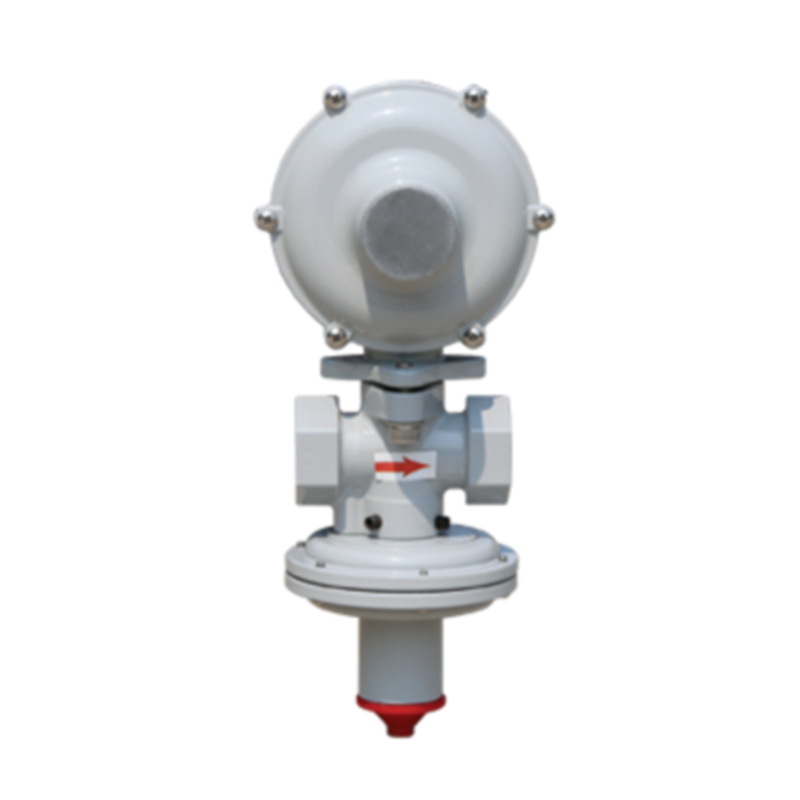

Gas Pressure Regulator Box/Cabinet

The gas coalescer filter is an essential component for any facility dealing with the purification and separation of gaseous mixtures. Its burgeoning importance in industries such as petrochemical, oil and gas, and manufacturing cannot be understated. Understanding its function, benefits, and applications can significantly enhance operational efficiency and ensure compliance with environmental and safety regulations, thus consolidating its position as an indispensable tool in modern engineering processes.

From a manufacturer's perspective, the authoritativeness of a gas coalescer filter is bolstered by adherence to quality assurance protocols and receiving endorsements from relevant industry bodies. Producers invest in Research and Development (R&D) to continuously refine filter material composition, increase durability, and improve overall filtration capability. This ongoing innovation ensures that their technology remains at the forefront of industry practices, capable of addressing evolving challenges in gas purification, and complies with escalating environmental demands. In applications such as the reduction of sulfur emissions or the prevention of corrosion in metal components, the trustworthiness of gas coalescer filters is a critical factor. Industries hold these filters to high standards, expecting them to perform under pressure while delivering consistent results. Extensive customer feedback and case studies highlight the filters' reliability, solidifying their reputation as a trusted solution for air quality control and operational efficiency. Furthermore, the gas coalescer filter’s relevance extends into sustainability frameworks adopted by industries globally. By reducing pollutants and focusing on eco-friendly operations, these filters contribute significantly to corporate social responsibility goals and the wider community’s environmental health. Their role in ensuring that gas emissions are thoroughly processed before release exemplifies a commitment to sustainable practices vital for long-term societal benefit. In summation, the proliferation of gas coalescer filters across numerous sectors underscores their critical role in industrial filtration applications. Their design, functionality, and effectiveness in maintaining purity and safety standards define their necessity. For entities seeking to enhance operational practices while adhering to robust environmental and safety protocols, investing in high-quality gas coalescer filters offers tangible benefits aligned with strategic industrial objectives, furthering the pursuit of excellence in manufacturing and process industries. As these technologies continue to evolve, their integration into standard practice not only promises operational improvements but also solidifies their standing in the realm of essential industrial solutions.

From a manufacturer's perspective, the authoritativeness of a gas coalescer filter is bolstered by adherence to quality assurance protocols and receiving endorsements from relevant industry bodies. Producers invest in Research and Development (R&D) to continuously refine filter material composition, increase durability, and improve overall filtration capability. This ongoing innovation ensures that their technology remains at the forefront of industry practices, capable of addressing evolving challenges in gas purification, and complies with escalating environmental demands. In applications such as the reduction of sulfur emissions or the prevention of corrosion in metal components, the trustworthiness of gas coalescer filters is a critical factor. Industries hold these filters to high standards, expecting them to perform under pressure while delivering consistent results. Extensive customer feedback and case studies highlight the filters' reliability, solidifying their reputation as a trusted solution for air quality control and operational efficiency. Furthermore, the gas coalescer filter’s relevance extends into sustainability frameworks adopted by industries globally. By reducing pollutants and focusing on eco-friendly operations, these filters contribute significantly to corporate social responsibility goals and the wider community’s environmental health. Their role in ensuring that gas emissions are thoroughly processed before release exemplifies a commitment to sustainable practices vital for long-term societal benefit. In summation, the proliferation of gas coalescer filters across numerous sectors underscores their critical role in industrial filtration applications. Their design, functionality, and effectiveness in maintaining purity and safety standards define their necessity. For entities seeking to enhance operational practices while adhering to robust environmental and safety protocols, investing in high-quality gas coalescer filters offers tangible benefits aligned with strategic industrial objectives, furthering the pursuit of excellence in manufacturing and process industries. As these technologies continue to evolve, their integration into standard practice not only promises operational improvements but also solidifies their standing in the realm of essential industrial solutions.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024