2 月 . 15, 2025 11:07

Back to list

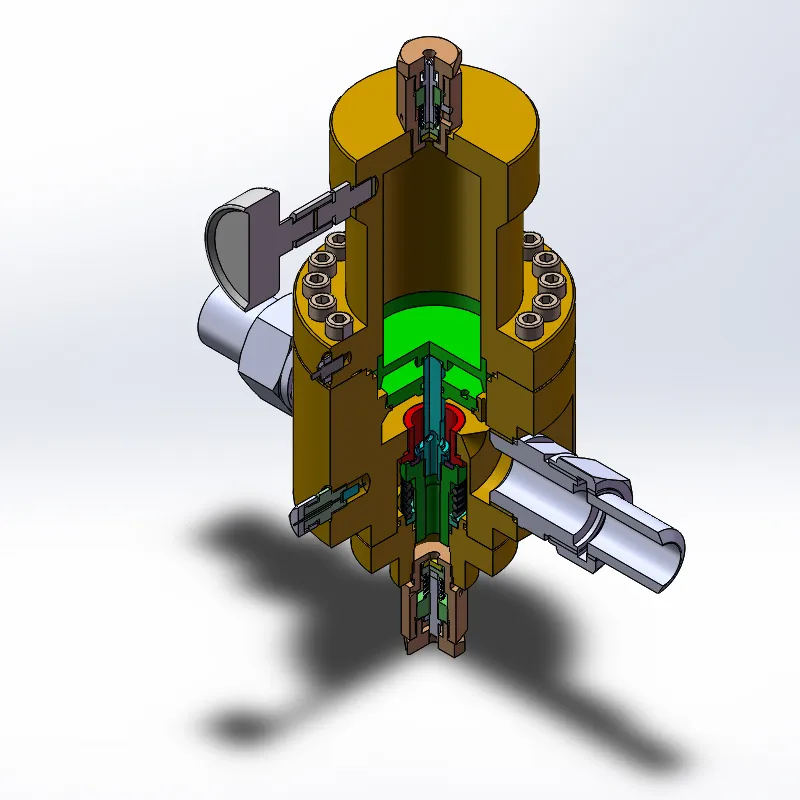

gas pressure reducer

Gas pressure reducers play a pivotal role in various industries, ensuring the safe and efficient operation of gas-driven systems. These devices, though often overlooked, are fundamental to maintaining optimal gas pressure levels, preventing potential system malfunctions, and guaranteeing safety. As the demand for energy-efficient solutions rises, understanding the intricacies of gas pressure reducers is more critical than ever.

From a technological innovation standpoint, modern gas pressure reducers are becoming increasingly sophisticated. Incorporating digital monitoring capabilities, these devices now offer real-time data analytics, allowing operators to predict maintenance requirements and optimize performance efficiently. Such advancements not only enhance the efficacy of pressure reducers but also contribute to a greener, more sustainable industrial environment. The authority of reliable manufacturers is crucial when choosing a gas pressure reducer. Reputable manufacturers comply with stringent international standards and regulatory requirements, ensuring product reliability and safety. They often provide comprehensive support services, including installation guidance, customization options, and ongoing technical assistance, which solidifies their reputation as leaders in the field. In this era of rapid technological advancement, the trustworthiness of gas pressure reducers is reinforced through rigorous testing and certification processes. Products that undergo extensive quality assurance protocols are more likely to withstand operational stress and deliver consistent performance over their lifecycle. Furthermore, transparent communication from manufacturers regarding material composition, operational limits, and care instructions enhances trust among users. In conclusion, the role of gas pressure reducers in modern industrial applications cannot be overstated. Their ability to ensure safety, operational efficiency, and system longevity makes them indispensable in various sectors. By leveraging cutting-edge technology, adhering to industry standards, and utilizing professional insights, gas pressure reducers continue to evolve, meeting the complex demands of contemporary gas systems. As stakeholders prioritize operational excellence and sustainability, gas pressure reducers stand at the forefront of energy innovation, symbolizing both a cornerstone of industrial safety and a beacon of progress in the energy sector.

From a technological innovation standpoint, modern gas pressure reducers are becoming increasingly sophisticated. Incorporating digital monitoring capabilities, these devices now offer real-time data analytics, allowing operators to predict maintenance requirements and optimize performance efficiently. Such advancements not only enhance the efficacy of pressure reducers but also contribute to a greener, more sustainable industrial environment. The authority of reliable manufacturers is crucial when choosing a gas pressure reducer. Reputable manufacturers comply with stringent international standards and regulatory requirements, ensuring product reliability and safety. They often provide comprehensive support services, including installation guidance, customization options, and ongoing technical assistance, which solidifies their reputation as leaders in the field. In this era of rapid technological advancement, the trustworthiness of gas pressure reducers is reinforced through rigorous testing and certification processes. Products that undergo extensive quality assurance protocols are more likely to withstand operational stress and deliver consistent performance over their lifecycle. Furthermore, transparent communication from manufacturers regarding material composition, operational limits, and care instructions enhances trust among users. In conclusion, the role of gas pressure reducers in modern industrial applications cannot be overstated. Their ability to ensure safety, operational efficiency, and system longevity makes them indispensable in various sectors. By leveraging cutting-edge technology, adhering to industry standards, and utilizing professional insights, gas pressure reducers continue to evolve, meeting the complex demands of contemporary gas systems. As stakeholders prioritize operational excellence and sustainability, gas pressure reducers stand at the forefront of energy innovation, symbolizing both a cornerstone of industrial safety and a beacon of progress in the energy sector.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024