2 月 . 19, 2025 10:46

Back to list

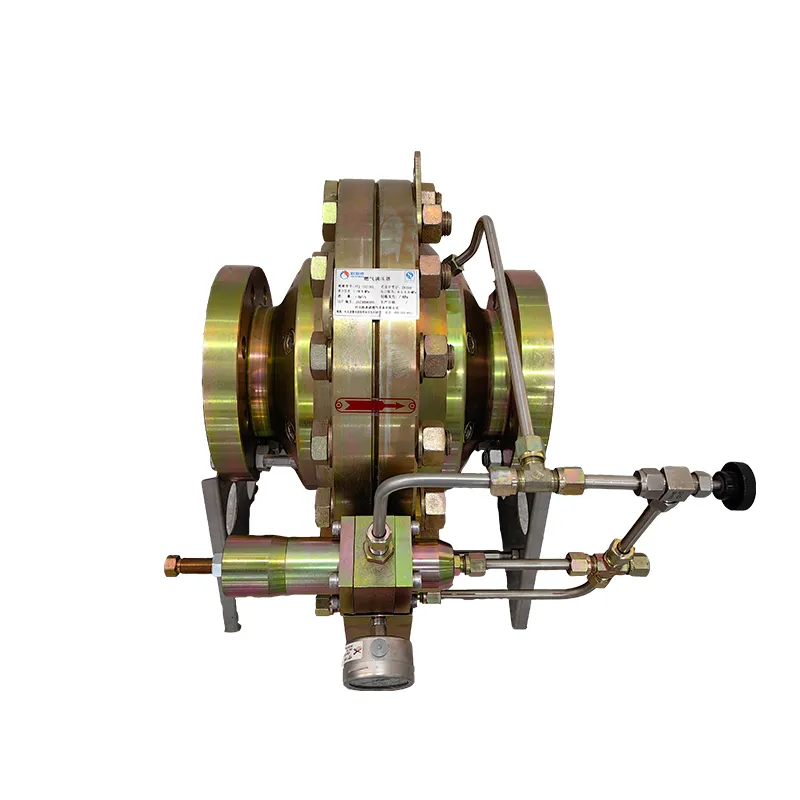

Gas Pretreatment Equipment - Filter Separators

A gas pressure reducing station (GPRS) plays a pivotal role in transforming high-pressure gas into the precise pressures required for safe transportation and end-user applications. As a linchpin in gas distribution networks, these stations maintain the efficacy, safety, and reliability expected in modern infrastructures, embodying years of engineering evolution and expertise.

Establishing authority in the field of gas pressure management is the result of documented performance evaluations, adherence to international standards such as ISO and API, and continuous innovation. Enterprises that design and implement GPRSs leverage cutting-edge technology, gaining insights from extensive field data to push the boundaries of what these stations can achieve. They are often at the forefront of integrating IoT solutions and AI predictive algorithms to anticipate maintenance needs, thus preemptively addressing potential operational disruptions. Reliability and trustworthiness in gas pressure reducing stations are built upon their track record of safety and efficiency over decades. These systems are not merely static installations but are subject to rigorous routine inspections, testing, and upgrades. A commitment to transparency in operational status and maintenance activities further solidifies trust among stakeholders, from regulatory bodies to end-users. Comprehensive training programs for operational staff ensure that the human element complements technological advancements, fostering a culture of safety and excellence. Incorporating sustainable practices within GPRS operations is gaining momentum, aligning with the global shift towards greener energy solutions. By utilizing materials and processes that minimize energy loss and environmental impact, these stations reduce carbon footprints while enhancing operational efficiency. The pursuit of sustainability extends to the implementation of renewable energy sources, such as solar panels, to power auxiliary systems, showcasing a commitment to ecological responsibility. A gas pressure reducing station is much more than a functional necessity; it represents the culmination of decades of technological evolution, expert collaboration, and a steadfast commitment to safety and reliability. In an era where precision and sustainability are paramount, these stations not only meet but redefine expectations, steadfastly securing their place within the backbone of modern gas distribution infrastructures.

Establishing authority in the field of gas pressure management is the result of documented performance evaluations, adherence to international standards such as ISO and API, and continuous innovation. Enterprises that design and implement GPRSs leverage cutting-edge technology, gaining insights from extensive field data to push the boundaries of what these stations can achieve. They are often at the forefront of integrating IoT solutions and AI predictive algorithms to anticipate maintenance needs, thus preemptively addressing potential operational disruptions. Reliability and trustworthiness in gas pressure reducing stations are built upon their track record of safety and efficiency over decades. These systems are not merely static installations but are subject to rigorous routine inspections, testing, and upgrades. A commitment to transparency in operational status and maintenance activities further solidifies trust among stakeholders, from regulatory bodies to end-users. Comprehensive training programs for operational staff ensure that the human element complements technological advancements, fostering a culture of safety and excellence. Incorporating sustainable practices within GPRS operations is gaining momentum, aligning with the global shift towards greener energy solutions. By utilizing materials and processes that minimize energy loss and environmental impact, these stations reduce carbon footprints while enhancing operational efficiency. The pursuit of sustainability extends to the implementation of renewable energy sources, such as solar panels, to power auxiliary systems, showcasing a commitment to ecological responsibility. A gas pressure reducing station is much more than a functional necessity; it represents the culmination of decades of technological evolution, expert collaboration, and a steadfast commitment to safety and reliability. In an era where precision and sustainability are paramount, these stations not only meet but redefine expectations, steadfastly securing their place within the backbone of modern gas distribution infrastructures.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024