2 月 . 03, 2025 04:20

Back to list

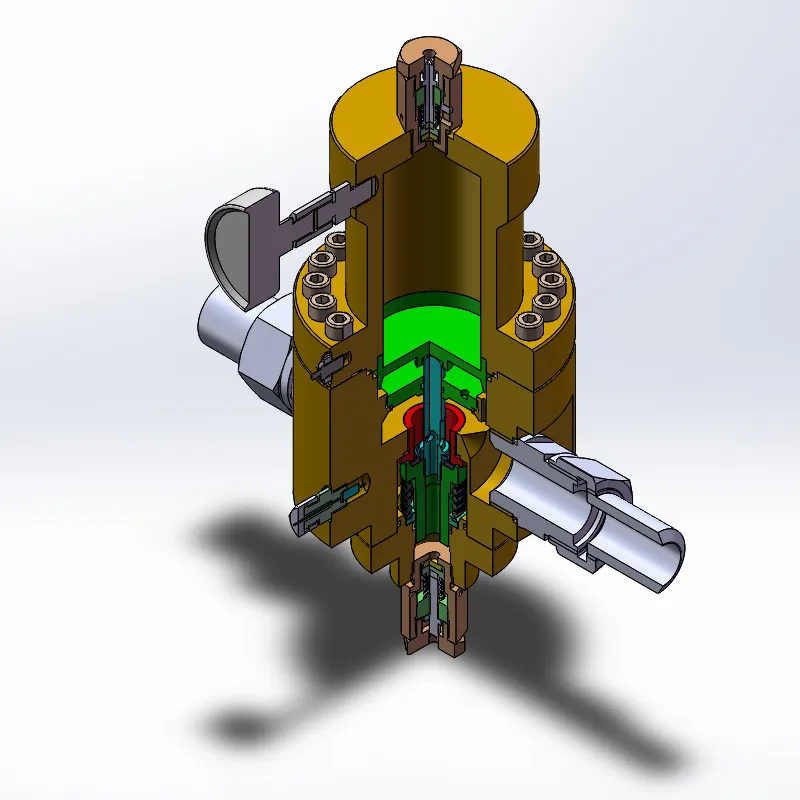

Gas Pretreatment Equipment - Filter Separators

Gas Pressure Regulator Valves Enhancing Efficiency and Safety in Gas Systems

Trustworthiness in the context of gas pressure regulator valves is linked to the transparency of information provided by manufacturers and suppliers. It is crucial for suppliers to offer comprehensive technical documentation, including maintenance manuals, installation guides, and troubleshooting tips. Detailed specifications and clear instructions foster confidence in product performance and long-term reliability. Additionally, manufacturers enhance trust through customer service excellence, offering prompt and supportive response to any inquiries or concerns. For those managing gas systems, selecting a reliable gas pressure regulator valve is a multifaceted decision. Consideration must be given to the type of gas being used, the required flow rate, and the pressure range. Expert advice from the manufacturer can guide this selection, ensuring compatibility and peak performance. Technological advancements continue to shape the landscape of gas pressure regulator valves. Modern designs incorporate smart technology for enhanced monitoring and control. Digital interfaces allow users to monitor pressure and flow rates in real time, adjusting settings remotely to accommodate different operational needs or respond to changes in the system. This integration of IoT capabilities not only boosts safety but also contributes to significant cost savings through predictive maintenance and reduced downtime. In conclusion, the world of gas pressure regulator valves is both complex and integral to many gas applications worldwide. The combination of user experience, technical expertise, and a commitment to quality and safety ensures these devices meet the rigorous demands of contemporary gas systems. By adhering to global standards and leveraging cutting-edge technology, manufacturers continue to innovate, offering solutions that enhance efficiency and safety across diverse industries. For stakeholders, partnering with reputable suppliers and staying informed on the latest developments is essential for ensuring the optimal functionality of their gas systems, ultimately leading to improved operational outcomes.

Trustworthiness in the context of gas pressure regulator valves is linked to the transparency of information provided by manufacturers and suppliers. It is crucial for suppliers to offer comprehensive technical documentation, including maintenance manuals, installation guides, and troubleshooting tips. Detailed specifications and clear instructions foster confidence in product performance and long-term reliability. Additionally, manufacturers enhance trust through customer service excellence, offering prompt and supportive response to any inquiries or concerns. For those managing gas systems, selecting a reliable gas pressure regulator valve is a multifaceted decision. Consideration must be given to the type of gas being used, the required flow rate, and the pressure range. Expert advice from the manufacturer can guide this selection, ensuring compatibility and peak performance. Technological advancements continue to shape the landscape of gas pressure regulator valves. Modern designs incorporate smart technology for enhanced monitoring and control. Digital interfaces allow users to monitor pressure and flow rates in real time, adjusting settings remotely to accommodate different operational needs or respond to changes in the system. This integration of IoT capabilities not only boosts safety but also contributes to significant cost savings through predictive maintenance and reduced downtime. In conclusion, the world of gas pressure regulator valves is both complex and integral to many gas applications worldwide. The combination of user experience, technical expertise, and a commitment to quality and safety ensures these devices meet the rigorous demands of contemporary gas systems. By adhering to global standards and leveraging cutting-edge technology, manufacturers continue to innovate, offering solutions that enhance efficiency and safety across diverse industries. For stakeholders, partnering with reputable suppliers and staying informed on the latest developments is essential for ensuring the optimal functionality of their gas systems, ultimately leading to improved operational outcomes.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024