2 月 . 15, 2025 04:38

Back to list

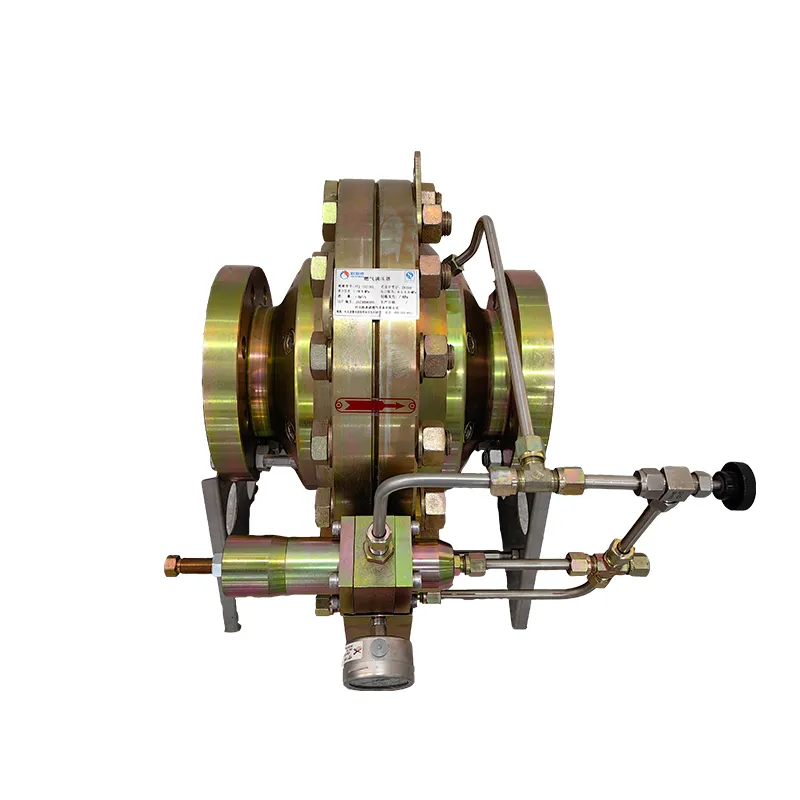

pneumatic valve

Choosing the Right Pneumatic Valve An Expert’s Perspective

The expertise in selecting the right pneumatic valve necessitates a deep understanding of the specific industrial application. Key considerations include the valve’s size, response time, pressure range, and material compatibility. For example, valves used in food and beverage industries often require compliance with stringent sanitary standards and are typically made from stainless steel. Material selection gains prominence in pneumatic valve applications subject to corrosive environments or extreme temperatures. Nitrile rubber seals may suffice for general use, but EPDM or Viton might be essential when confronting aggressive chemicals or higher temperatures. Fast response times are crucial in dynamic systems demanding quick adjustments, such as manufacturing systems requiring rapid changeovers to accommodate versatile product lines. Pneumatic systems often favor light, corrosion-resistant aluminum valves for these applications. Additionally, energy efficiency emerges as a modern consideration, given the rising costs of energy and the push for sustainable industrial practices. With energy consumption being a significant cost factor for pneumatic systems, selecting valves designed to minimize air leakage and enable precise flow control can substantially reduce operational costs. When integrating pneumatic valves, attention must be paid to the calibrations and specifications provided by reputable manufacturers. Vendors with strong track records in the industry, offering detailed product documentation and support, can significantly contribute to the effectiveness and reliability of your pneumatic systems. In leveraging pneumatic valves for automation, innovative trends such as the integration of smart valves capable of monitoring performance and self-diagnosing issues are gaining traction. These advanced pneumatic components enhance system efficiency and minimize downtime through predictive maintenance, reducing overall lifecycle costs. In conclusion, pneumatic valves are indispensable in achieving a seamless flow of operations across diverse industrial sectors. Selecting the right valve signifies more than just a purchase; it is a strategic decision requiring comprehensive knowledge and expert insight. For sustained operational success, partnering with experienced professionals and adhering to internationally recognized standards is essential. Thus, investing in reliable pneumatic solutions becomes a cornerstone of industrial efficacy and innovation.

The expertise in selecting the right pneumatic valve necessitates a deep understanding of the specific industrial application. Key considerations include the valve’s size, response time, pressure range, and material compatibility. For example, valves used in food and beverage industries often require compliance with stringent sanitary standards and are typically made from stainless steel. Material selection gains prominence in pneumatic valve applications subject to corrosive environments or extreme temperatures. Nitrile rubber seals may suffice for general use, but EPDM or Viton might be essential when confronting aggressive chemicals or higher temperatures. Fast response times are crucial in dynamic systems demanding quick adjustments, such as manufacturing systems requiring rapid changeovers to accommodate versatile product lines. Pneumatic systems often favor light, corrosion-resistant aluminum valves for these applications. Additionally, energy efficiency emerges as a modern consideration, given the rising costs of energy and the push for sustainable industrial practices. With energy consumption being a significant cost factor for pneumatic systems, selecting valves designed to minimize air leakage and enable precise flow control can substantially reduce operational costs. When integrating pneumatic valves, attention must be paid to the calibrations and specifications provided by reputable manufacturers. Vendors with strong track records in the industry, offering detailed product documentation and support, can significantly contribute to the effectiveness and reliability of your pneumatic systems. In leveraging pneumatic valves for automation, innovative trends such as the integration of smart valves capable of monitoring performance and self-diagnosing issues are gaining traction. These advanced pneumatic components enhance system efficiency and minimize downtime through predictive maintenance, reducing overall lifecycle costs. In conclusion, pneumatic valves are indispensable in achieving a seamless flow of operations across diverse industrial sectors. Selecting the right valve signifies more than just a purchase; it is a strategic decision requiring comprehensive knowledge and expert insight. For sustained operational success, partnering with experienced professionals and adhering to internationally recognized standards is essential. Thus, investing in reliable pneumatic solutions becomes a cornerstone of industrial efficacy and innovation.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024