2 月 . 05, 2025 00:33

Back to list

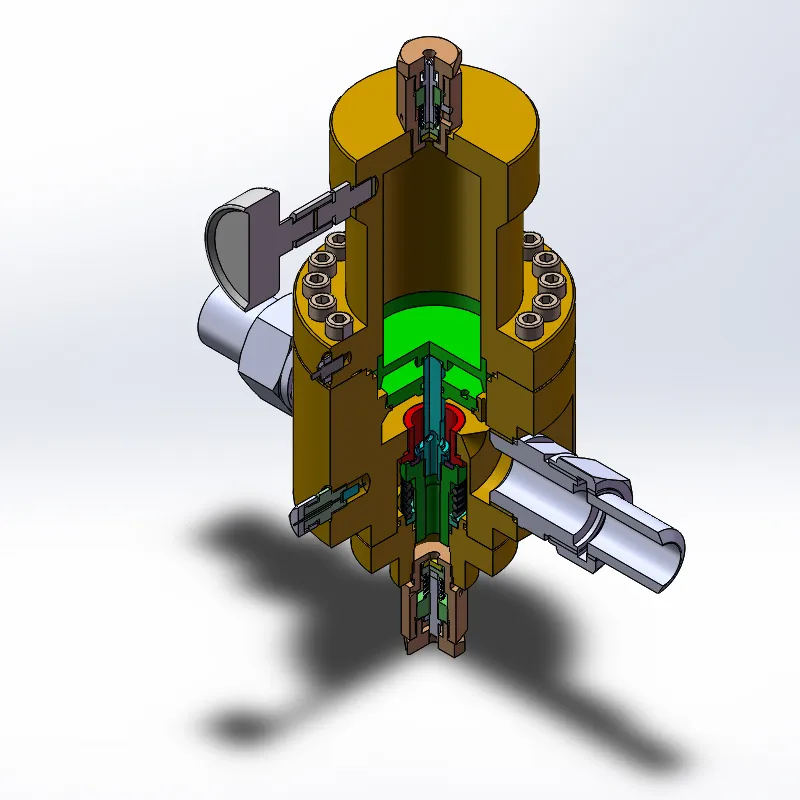

pressure reducing device

Pressure reducing devices, commonly referred to as pressure regulators, play a pivotal role in maintaining optimal performance across various industries. These devices are essential in ensuring the safe and efficient management of pressure levels in systems, preventing damage, leaks, and enhancing operational longevity. In this comprehensive guide, we delve into the workings, applications, and advantages of pressure reducing devices, shedding light on why they are indispensable in modern technology and industry.

From an authoritative standpoint, pressure regulators must comply with industry standards and certifications, such as those from the American Society of Mechanical Engineers (ASME) or International Organization for Standardization (ISO). These certifications guarantee that the devices can handle designated pressures and applications, adding a layer of trustworthiness vital for stakeholders and engineers alike. In terms of expertise, understanding the nuanced mechanisms within pressure reducing devices is essential for optimal performance. Advanced models offer features such as tamper-proof settings, built-in gauges, and automatic shutdown in the event of system failure. These features not only enhance functionality but also provide additional indicators for maintenance, thereby preventing potential issues before they manifest. Real-world experience shows that integrating pressure reducing devices into existing systems often results in increased system uptime and resilience. Stories from field operators highlight cases where minor adjustments in pressure regulation have led to significant improvements in service delivery and efficiency. This experiential knowledge underscores the importance of regular training and system audits, ensuring that personnel are well-versed in the operation and maintenance of these devices. In conclusion, pressure reducing devices are a cornerstone of effective pressure management. Their strategic use leads to enhanced safety, increased cost efficiency, and improved equipment longevity. As industries evolve and demand higher standards of operation and safety, the role of precision-engineered pressure regulators becomes increasingly crucial. Stakeholders must continue to invest in accurate and reliable pressure reducing solutions to uphold the integrity and performance of their operations. Through expert application and adherence to industry standards, these devices ensure systems operate smoothly, safely, and economically.

From an authoritative standpoint, pressure regulators must comply with industry standards and certifications, such as those from the American Society of Mechanical Engineers (ASME) or International Organization for Standardization (ISO). These certifications guarantee that the devices can handle designated pressures and applications, adding a layer of trustworthiness vital for stakeholders and engineers alike. In terms of expertise, understanding the nuanced mechanisms within pressure reducing devices is essential for optimal performance. Advanced models offer features such as tamper-proof settings, built-in gauges, and automatic shutdown in the event of system failure. These features not only enhance functionality but also provide additional indicators for maintenance, thereby preventing potential issues before they manifest. Real-world experience shows that integrating pressure reducing devices into existing systems often results in increased system uptime and resilience. Stories from field operators highlight cases where minor adjustments in pressure regulation have led to significant improvements in service delivery and efficiency. This experiential knowledge underscores the importance of regular training and system audits, ensuring that personnel are well-versed in the operation and maintenance of these devices. In conclusion, pressure reducing devices are a cornerstone of effective pressure management. Their strategic use leads to enhanced safety, increased cost efficiency, and improved equipment longevity. As industries evolve and demand higher standards of operation and safety, the role of precision-engineered pressure regulators becomes increasingly crucial. Stakeholders must continue to invest in accurate and reliable pressure reducing solutions to uphold the integrity and performance of their operations. Through expert application and adherence to industry standards, these devices ensure systems operate smoothly, safely, and economically.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024