1 月 . 15, 2025 09:16

Back to list

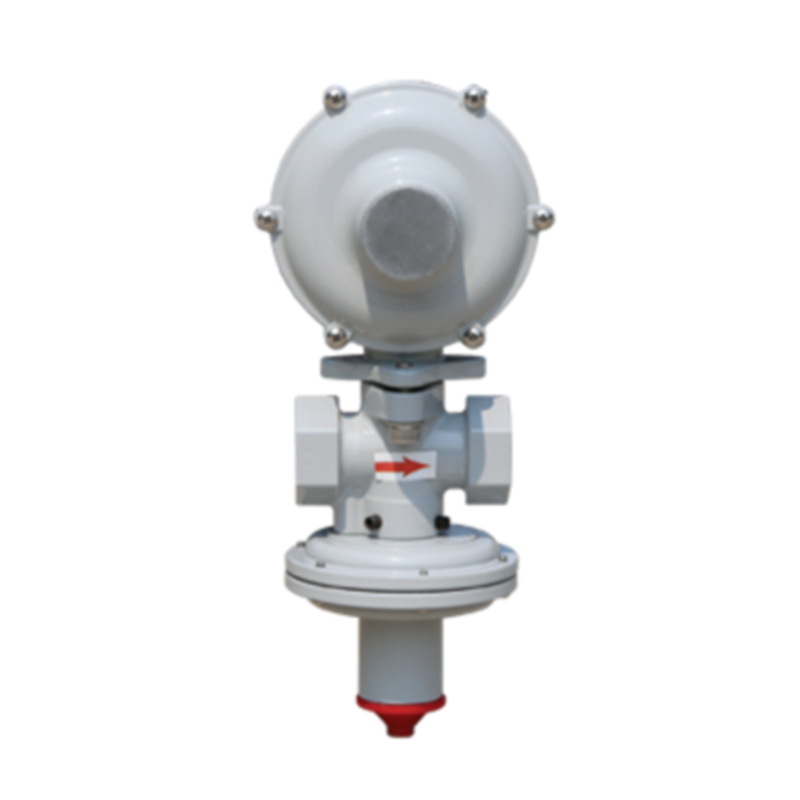

pressure vessel

Pressure vessels play a critical role in various industries, such as chemical processing, energy, oil and gas, and pharmaceuticals. Understanding the complexities involved in their design, operation, and maintenance is essential for ensuring safety and optimizing performance.

Trust in pressure vessel systems is reinforced through rigorous testing protocols. Hydrostatic testing is one such method where the vessel is filled with water and pressurized to check its ability to hold the intended pressures without leaking or rupturing. Regular inspections and maintenance routines are critical to identifying potential issues before they escalate, thereby ensuring the vessel’s operation remains safe and reliable. Moreover, leveraging real-world experience in pressure vessel management provides invaluable insights. Companies that have a proven track record in safely managing these vessels under various challenging conditions offer case studies that can guide new users in implementing best practices. These experiences not only build trust but also help in recognizing early signs of wear and stress, enabling proactive measures. Ultimately, the combination of expertise, adherence to established standards, collaboration with authoritative partners, and reliance on real-world experiences culminates in pressure vessel solutions that are not only effective but also engender trust and confidence across industries.

Trust in pressure vessel systems is reinforced through rigorous testing protocols. Hydrostatic testing is one such method where the vessel is filled with water and pressurized to check its ability to hold the intended pressures without leaking or rupturing. Regular inspections and maintenance routines are critical to identifying potential issues before they escalate, thereby ensuring the vessel’s operation remains safe and reliable. Moreover, leveraging real-world experience in pressure vessel management provides invaluable insights. Companies that have a proven track record in safely managing these vessels under various challenging conditions offer case studies that can guide new users in implementing best practices. These experiences not only build trust but also help in recognizing early signs of wear and stress, enabling proactive measures. Ultimately, the combination of expertise, adherence to established standards, collaboration with authoritative partners, and reliance on real-world experiences culminates in pressure vessel solutions that are not only effective but also engender trust and confidence across industries.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024