2 月 . 11, 2025 09:44

Back to list

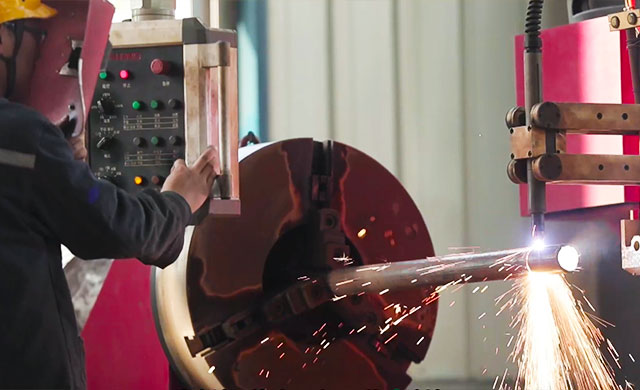

pressure vessel

Pressure vessels are integral components in various industries, renowned for their ability to hold gases or liquids at a pressure substantially different from the ambient pressure. They are ubiquitous in fields such as petrochemicals, pharmaceuticals, power generation, and food processing. A deep dive into their construction, usage, and safety protocols underscores their critical role and unveils insights into enhancing operational efficiency and safety standards.

Moreover, the expertise in designing pressure vessels extends beyond mere construction. Engineers must also consider the fluid dynamics within the vessel, ensuring optimal flow and minimal pressure drop, which can significantly affect operational efficiency. Baffles and other internal structures might be used to regulate the flow, aiding in even distribution of pressure and temperature, and enhancing the efficiency of the heat exchange processes. The authority in the field of pressure vessels also rests significantly on adherence to global standards and regulations. ASME standards are internationally recognized, ensuring that vessels constructed under these guidelines are of the highest quality. Compliance is not just about meeting legal obligations but is a testament to the manufacturer's commitment to quality and safety, instilling trust among clients and stakeholders. Trustworthiness in pressure vessel providers can further be ensured by scrutinizing their track record and certifications. A well-regarded pressure vessel manufacturer will have a history of successful projects and client testimonials, bolstering their reputation. Certifications from recognized bodies provide assurance of their capabilities and dedication to maintaining high safety and quality standards. In conclusion, pressure vessels are sophisticated engineering marvels critical to diverse industries. Their design, fabrication, and maintenance require a harmonious blend of experience, expertise, authority, and trustworthiness. As industries evolve and technology advances, pressure vessels will undoubtedly continue to see innovations that not only enhance their efficiency and safety but also contribute significantly to the sustainability and productivity of industrial operations worldwide.

Moreover, the expertise in designing pressure vessels extends beyond mere construction. Engineers must also consider the fluid dynamics within the vessel, ensuring optimal flow and minimal pressure drop, which can significantly affect operational efficiency. Baffles and other internal structures might be used to regulate the flow, aiding in even distribution of pressure and temperature, and enhancing the efficiency of the heat exchange processes. The authority in the field of pressure vessels also rests significantly on adherence to global standards and regulations. ASME standards are internationally recognized, ensuring that vessels constructed under these guidelines are of the highest quality. Compliance is not just about meeting legal obligations but is a testament to the manufacturer's commitment to quality and safety, instilling trust among clients and stakeholders. Trustworthiness in pressure vessel providers can further be ensured by scrutinizing their track record and certifications. A well-regarded pressure vessel manufacturer will have a history of successful projects and client testimonials, bolstering their reputation. Certifications from recognized bodies provide assurance of their capabilities and dedication to maintaining high safety and quality standards. In conclusion, pressure vessels are sophisticated engineering marvels critical to diverse industries. Their design, fabrication, and maintenance require a harmonious blend of experience, expertise, authority, and trustworthiness. As industries evolve and technology advances, pressure vessels will undoubtedly continue to see innovations that not only enhance their efficiency and safety but also contribute significantly to the sustainability and productivity of industrial operations worldwide.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024