2 月 . 16, 2025 02:21

Back to list

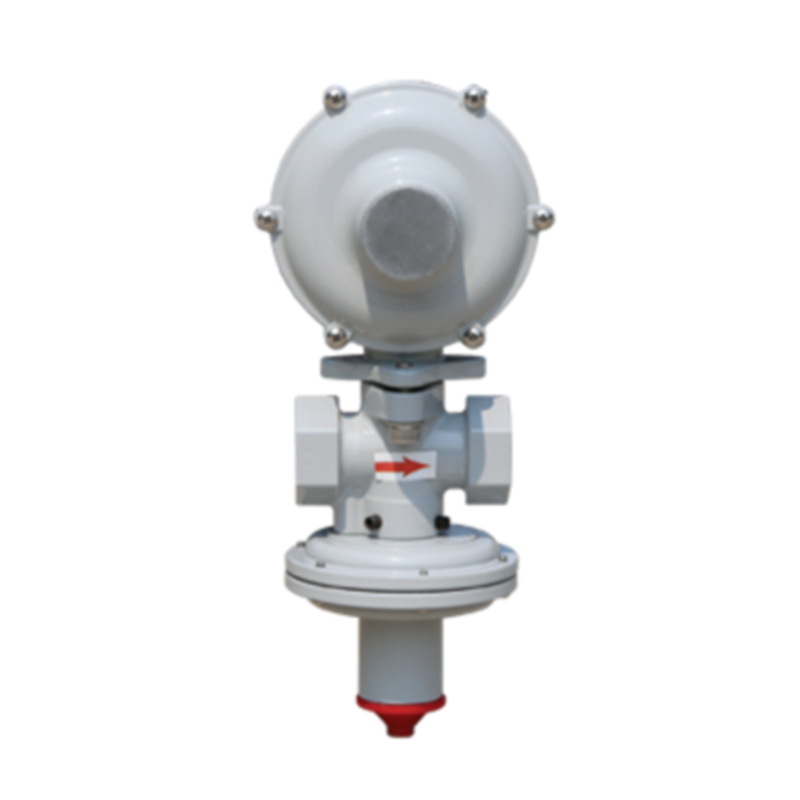

Gas Filter

Reducing stations play a crucial role in various industrial applications, serving as pivotal components in the regulation of pressure for different types of systems. The complexity and efficiency of these stations are paramount to ensure both safety and the optimal performance of machinery and processes across industries such as gas distribution, chemical manufacturing, and even in residential areas.

The industry reveres manufacturers who deliver reliable and innovative reducing station solutions. Companies known for their authoritative stance in equipment supply often have a proven track record of quality assurance. Their product lines are typically subjected to rigorous testing and certification processes to verify their integrity and reliability under various conditions. Such practices build trust, reassuring clients of both safety and efficiency. Experience and collaboration with industrial leaders also highlight the growing trend towards more sustainable and energy-efficient reducing stations. As industries increasingly focus on reducing their carbon footprint, integrating eco-friendly technologies into reducing stations has become a priority. Leveraging advanced materials and design improvements, some manufacturers now offer solutions that reduce emissions and improve energy conversion efficiency, aligning with global sustainability goals. For businesses looking to install or upgrade their pressure control systems, understanding the nuances and expertise required in the selection, use, and maintenance of reducing stations is paramount. Engaging with reputable suppliers who offer not just products but also comprehensive support and expert advice ensures the longevity and efficacy of the system. Properly understood and applied, reducing stations bolster not only individual systems but the broader operational strategies aiming for excellence and safety in various industries. In conclusion, reducing stations are indispensable components characterized by their critical role in pressure management across numerous applications. With expertise in their design, authoritative technology integration, and a growing emphasis on sustainability, these systems exemplify the fusion of reliability, efficiency, and safety. Trust in their capabilities is reinforced through industry standards and the ongoing innovation led by reputable manufacturers, ensuring they remain foundational to industrial success and safety.

The industry reveres manufacturers who deliver reliable and innovative reducing station solutions. Companies known for their authoritative stance in equipment supply often have a proven track record of quality assurance. Their product lines are typically subjected to rigorous testing and certification processes to verify their integrity and reliability under various conditions. Such practices build trust, reassuring clients of both safety and efficiency. Experience and collaboration with industrial leaders also highlight the growing trend towards more sustainable and energy-efficient reducing stations. As industries increasingly focus on reducing their carbon footprint, integrating eco-friendly technologies into reducing stations has become a priority. Leveraging advanced materials and design improvements, some manufacturers now offer solutions that reduce emissions and improve energy conversion efficiency, aligning with global sustainability goals. For businesses looking to install or upgrade their pressure control systems, understanding the nuances and expertise required in the selection, use, and maintenance of reducing stations is paramount. Engaging with reputable suppliers who offer not just products but also comprehensive support and expert advice ensures the longevity and efficacy of the system. Properly understood and applied, reducing stations bolster not only individual systems but the broader operational strategies aiming for excellence and safety in various industries. In conclusion, reducing stations are indispensable components characterized by their critical role in pressure management across numerous applications. With expertise in their design, authoritative technology integration, and a growing emphasis on sustainability, these systems exemplify the fusion of reliability, efficiency, and safety. Trust in their capabilities is reinforced through industry standards and the ongoing innovation led by reputable manufacturers, ensuring they remain foundational to industrial success and safety.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024