2 月 . 19, 2025 01:44

Back to list

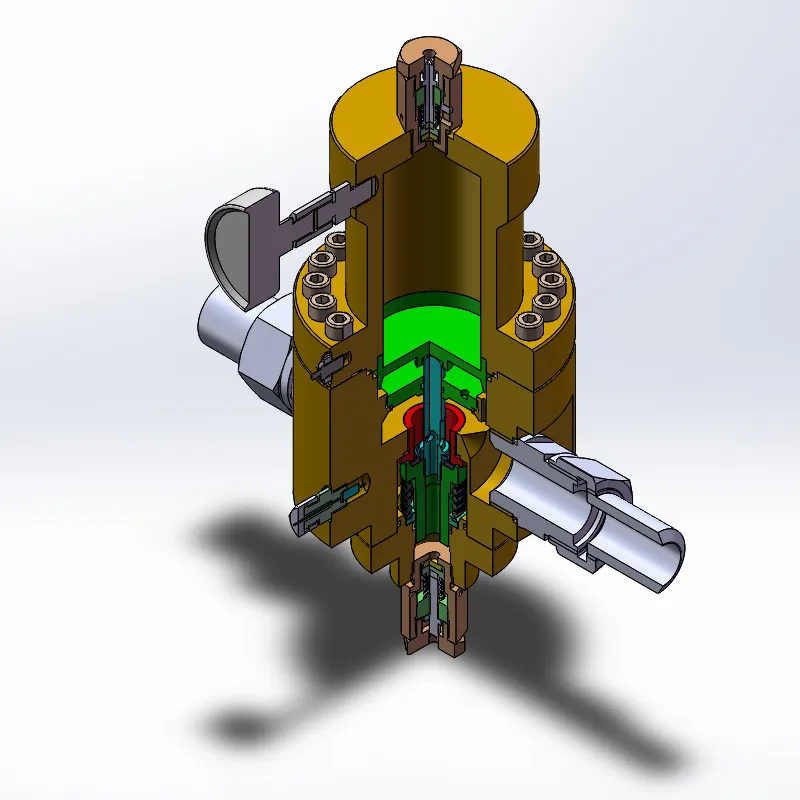

relief valves

Relief valves play a crucial role in ensuring the safety and efficiency of numerous industrial systems. From preventing catastrophic failures in pipelines to maintaining optimal pressure levels in heating systems, these devices are indispensable in various applications.

It is also crucial to keep up with regular maintenance and inspection schedules. Relief valves should be tested periodically to ensure they open at the correct set pressure and reseat properly after activation. Neglecting this can result in valve malfunction, leaving the system vulnerable to overpressure incidents. Implementing a robust maintenance strategy not only extends the life of a relief valve but enhances the overall reliability of the system it protects. Industry standards and certifications form the backbone of trustworthiness in relief valve applications. Valves conforming to standards such as API, ASME, or ISO assure users of their quality and reliability. Manufacturers who invest in these certifications demonstrate their commitment to safety, engineering excellence, and customer trust, establishing themselves as authorities in the field. For industries utilizing highly specialized equipment, partnering with a reliable relief valve supplier provides unparalleled expertise. These suppliers offer valuable insights into product innovations and practical applications, ensuring that clients are equipped with the most effective solutions for their unique operational challenges. Moreover, a reputable supplier provides adequate support in product selection, installation guidance, and aftermarket services, reinforcing the client’s confidence in the product’s performance. In conclusion, the role of relief valves in industrial systems is fundamental not just for safety, but for maintaining uninterrupted productivity. Through careful selection, rigorous maintenance, and reliance on expert guidance, businesses can harness the full potential of their pressure systems while safeguarding their operations. As industries continue to evolve, relief valves remain essential components, underscoring the importance of meticulous planning and execution in pressure management.

It is also crucial to keep up with regular maintenance and inspection schedules. Relief valves should be tested periodically to ensure they open at the correct set pressure and reseat properly after activation. Neglecting this can result in valve malfunction, leaving the system vulnerable to overpressure incidents. Implementing a robust maintenance strategy not only extends the life of a relief valve but enhances the overall reliability of the system it protects. Industry standards and certifications form the backbone of trustworthiness in relief valve applications. Valves conforming to standards such as API, ASME, or ISO assure users of their quality and reliability. Manufacturers who invest in these certifications demonstrate their commitment to safety, engineering excellence, and customer trust, establishing themselves as authorities in the field. For industries utilizing highly specialized equipment, partnering with a reliable relief valve supplier provides unparalleled expertise. These suppliers offer valuable insights into product innovations and practical applications, ensuring that clients are equipped with the most effective solutions for their unique operational challenges. Moreover, a reputable supplier provides adequate support in product selection, installation guidance, and aftermarket services, reinforcing the client’s confidence in the product’s performance. In conclusion, the role of relief valves in industrial systems is fundamental not just for safety, but for maintaining uninterrupted productivity. Through careful selection, rigorous maintenance, and reliance on expert guidance, businesses can harness the full potential of their pressure systems while safeguarding their operations. As industries continue to evolve, relief valves remain essential components, underscoring the importance of meticulous planning and execution in pressure management.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024