1 月 . 15, 2025 09:23

Back to list

shut-off valve

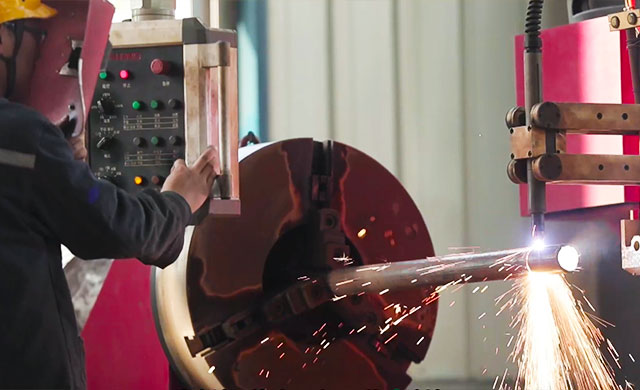

Shut-off valves play an essential role in any plumbing or industrial system, functioning as the gatekeepers of fluid flow. Designed to stop or regulate the passage of liquid or gas, these devices are integral in various applications, from household plumbing to large-scale industrial projects.

In terms of real-world applications, consider the testimony of seasoned industrial maintenance teams who often cite instances where high-quality shut-off valves have prevented costly downtime. For instance, during maintenance activities, being able to depend on the valve to securely stop fluid flow means that the team can work safely and efficiently. Such experiences reinforce the value of investing in premium shut-off valve solutions. Educational resources and training programs also play an essential role in fostering expertise and reliability in shut-off valve use. Workshops and certifications offer hands-on experience, teaching best practices in installation, maintenance, and trouble-shooting. Such programs increase the competence of operators, ensuring that they can handle various situations that may arise, thereby enhancing the overall trust in the system's reliability. In conclusion, shut-off valves are not just components, but vital elements that ensure the safety and efficiency of fluid systems. Their role transcends residential and industrial use, impacting the safety and operations significantly. Through a combination of expertise in material selection, trust in brand reliability, and firsthand experience in their practical application, shut-off valves continue to be indispensable in modern plumbing and industrial systems, underscoring their relevance in any pipeline infrastructure.

In terms of real-world applications, consider the testimony of seasoned industrial maintenance teams who often cite instances where high-quality shut-off valves have prevented costly downtime. For instance, during maintenance activities, being able to depend on the valve to securely stop fluid flow means that the team can work safely and efficiently. Such experiences reinforce the value of investing in premium shut-off valve solutions. Educational resources and training programs also play an essential role in fostering expertise and reliability in shut-off valve use. Workshops and certifications offer hands-on experience, teaching best practices in installation, maintenance, and trouble-shooting. Such programs increase the competence of operators, ensuring that they can handle various situations that may arise, thereby enhancing the overall trust in the system's reliability. In conclusion, shut-off valves are not just components, but vital elements that ensure the safety and efficiency of fluid systems. Their role transcends residential and industrial use, impacting the safety and operations significantly. Through a combination of expertise in material selection, trust in brand reliability, and firsthand experience in their practical application, shut-off valves continue to be indispensable in modern plumbing and industrial systems, underscoring their relevance in any pipeline infrastructure.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024