1 月 . 28, 2025 05:12

Back to list

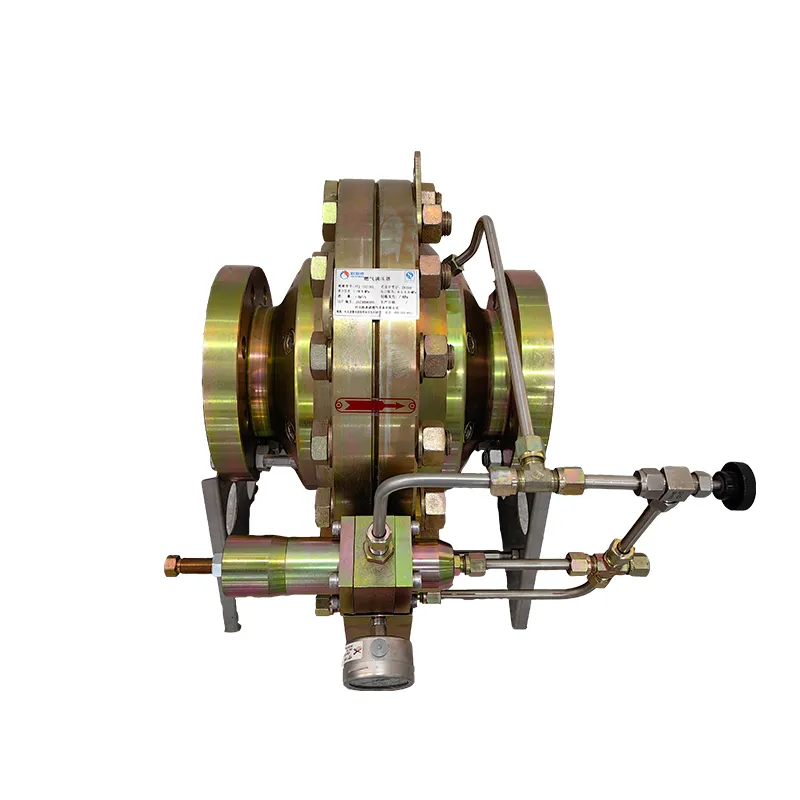

RFZ/*/* Gas Safety Relief Valve

Vent relief valves, a critical component in various industrial systems, ensure safe and efficient operations in sectors ranging from chemical manufacturing to oil and gas extraction. Drawing from years of experience and expertise in the field, this article aims to shed light on the importance, functioning, and selection criteria of vent relief valves, establishing their indispensability in industrial applications.

2. Material Compatibility Resistance to corrosive substances or adverse environmental conditions is a crucial factor. Valves made from materials such as stainless steel or specialized alloys are preferred in harsh environments. 3. Flow Capacity The valve must be able to handle the maximum expected flow rate to prevent over-pressurization effectively. 4. Regulatory Compliance Adherence to industry standards such as ASME or API ensures that the valve is suitable for its intended application. 5. Operational Reliability The valve should exhibit high reliability, demanding minimal maintenance and offering prolonged service life, thereby ensuring uninterrupted safety functions. Latest Innovations and Trends The market for vent relief valves is witnessing significant advancements with the integration of smart technologies. Modern valves are now equipped with IoT capabilities, allowing for real-time monitoring and predictive maintenance. This technological progression not only enhances operational safety but also reduces downtime and maintenance costs, promising a substantial return on investment. In addition, development in material science has led to the production of valves capable of withstanding extreme conditions with improved durability and efficiency, addressing the evolving needs of various industries. Conclusion Vent relief valves stand as a testament to the progress in industrial safety and operations. With rigorous attention to detail in their design and implementation, these valves significantly enhance system safety and reliability. Professionals and engineers prioritize the optimal selection and maintenance of these valves, ensuring they meet the highest standards of safety and performance. The ongoing innovations further cement their role in safeguarding industrial processes, highlighting the continuous need for expertise and authority in choosing the right solution tailored to specific operational needs.

2. Material Compatibility Resistance to corrosive substances or adverse environmental conditions is a crucial factor. Valves made from materials such as stainless steel or specialized alloys are preferred in harsh environments. 3. Flow Capacity The valve must be able to handle the maximum expected flow rate to prevent over-pressurization effectively. 4. Regulatory Compliance Adherence to industry standards such as ASME or API ensures that the valve is suitable for its intended application. 5. Operational Reliability The valve should exhibit high reliability, demanding minimal maintenance and offering prolonged service life, thereby ensuring uninterrupted safety functions. Latest Innovations and Trends The market for vent relief valves is witnessing significant advancements with the integration of smart technologies. Modern valves are now equipped with IoT capabilities, allowing for real-time monitoring and predictive maintenance. This technological progression not only enhances operational safety but also reduces downtime and maintenance costs, promising a substantial return on investment. In addition, development in material science has led to the production of valves capable of withstanding extreme conditions with improved durability and efficiency, addressing the evolving needs of various industries. Conclusion Vent relief valves stand as a testament to the progress in industrial safety and operations. With rigorous attention to detail in their design and implementation, these valves significantly enhance system safety and reliability. Professionals and engineers prioritize the optimal selection and maintenance of these valves, ensuring they meet the highest standards of safety and performance. The ongoing innovations further cement their role in safeguarding industrial processes, highlighting the continuous need for expertise and authority in choosing the right solution tailored to specific operational needs.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024