2 月 . 14, 2025 09:24

Back to list

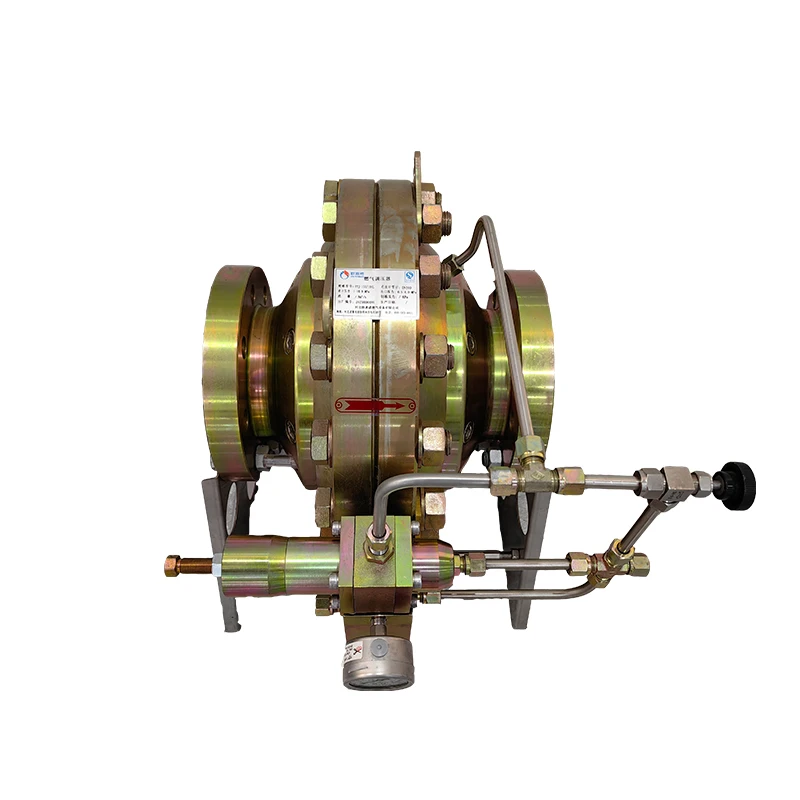

صمام التحكم الهوائي

In the realm of industrial automation, the pneumatic control valve [صمام التحكم الهوائي] has emerged as a cornerstone component, sought after for its precision and reliability. A pneumatic control valve is essentially an assembly that directs or regulates the flow of a fluid (liquids, gas, slurries) by closing, opening, or partially obstructing various passageways. They are driven by compressed air, which makes them particularly unique and advantageous over electric actuators in specific applications.

Building trustworthiness with these valves involves selecting products from reputable manufacturers known for their adherence to stringent international standards such as ASME, ISO, and ANSI. These standards ensure that the valves meet rigorous safety, reliability, and performance criteria. Furthermore, routine maintenance and calibration of pneumatic control valves are crucial for sustaining their operational integrity. This involves regular inspection of the actuator and positioner, and ensuring that seals and gaskets are in optimal condition, thereby fortifying their longevity and reliable operation. For those experienced in the field, employing these valves offers a unique combination of simplicity and sophistication. Although they consist of few moving parts, the precision in their operation is remarkable. Industries continuously seek to leverage technology to enhance valve performance, incorporating smart systems and feedback loops to automate processes further. This technology enables operators to monitor valve performance in real-time, predict maintenance needs, and optimize operational efficiencies resourcefully. Current trends are witnessing an integration of IoT and advanced data analytics with pneumatic control valves, whereby remote monitoring and digital maintenance strategies are revolutionizing process control. This convergence of traditional engineering principles with modern technology is setting new benchmarks in efficiency and reliability, driving innovation in sector-specific applications. The future of pneumatic control valves is promising, buoyed by continuous technological advancements and an ever-growing demand for efficient, robust, and reliable process automation solutions across various industries. In essence, these valves not only exemplify precision and efficiency but also embody the very spirit of innovation tailored to meet the dynamic needs of modern industries.

Building trustworthiness with these valves involves selecting products from reputable manufacturers known for their adherence to stringent international standards such as ASME, ISO, and ANSI. These standards ensure that the valves meet rigorous safety, reliability, and performance criteria. Furthermore, routine maintenance and calibration of pneumatic control valves are crucial for sustaining their operational integrity. This involves regular inspection of the actuator and positioner, and ensuring that seals and gaskets are in optimal condition, thereby fortifying their longevity and reliable operation. For those experienced in the field, employing these valves offers a unique combination of simplicity and sophistication. Although they consist of few moving parts, the precision in their operation is remarkable. Industries continuously seek to leverage technology to enhance valve performance, incorporating smart systems and feedback loops to automate processes further. This technology enables operators to monitor valve performance in real-time, predict maintenance needs, and optimize operational efficiencies resourcefully. Current trends are witnessing an integration of IoT and advanced data analytics with pneumatic control valves, whereby remote monitoring and digital maintenance strategies are revolutionizing process control. This convergence of traditional engineering principles with modern technology is setting new benchmarks in efficiency and reliability, driving innovation in sector-specific applications. The future of pneumatic control valves is promising, buoyed by continuous technological advancements and an ever-growing demand for efficient, robust, and reliable process automation solutions across various industries. In essence, these valves not only exemplify precision and efficiency but also embody the very spirit of innovation tailored to meet the dynamic needs of modern industries.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024