2 月 . 14, 2025 09:45

Back to list

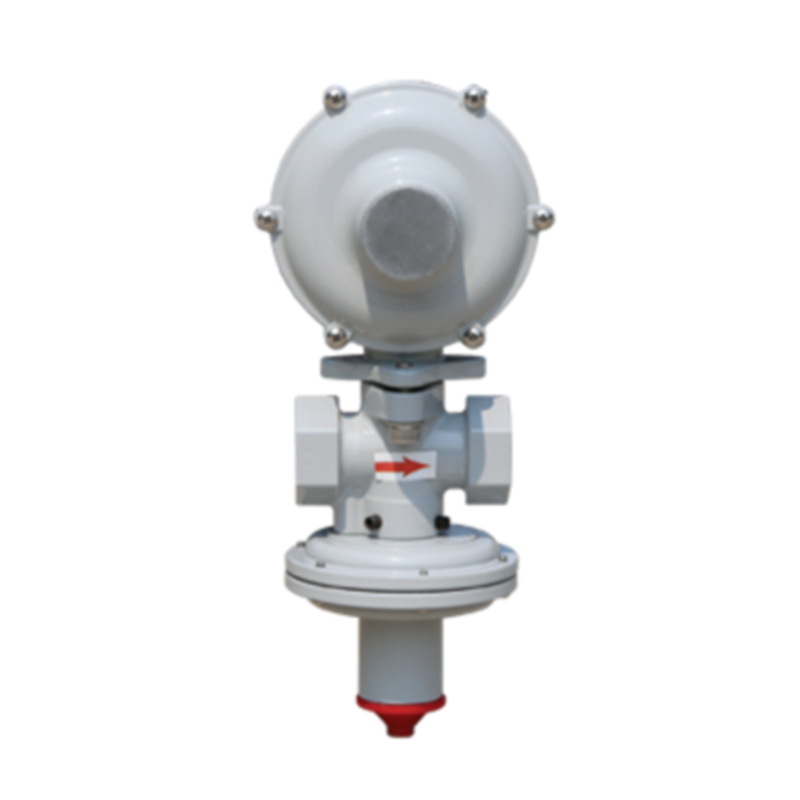

صمام الغاز الطبيعي

Gas valves play a critical role in the safe and efficient operation of natural gas systems. With an increasing global reliance on natural gas as a key energy source, understanding the nuances of gas valve technology becomes paramount. As experts in the field, we have examined various aspects of natural gas valves to provide authoritative insights that center around functionality, safety, and advancements in design.

Trustworthiness in the context of natural gas valves extends beyond the product itself to encompass the reputation of the manufacturers and suppliers. Leading companies invest significantly in research and development to innovate and enhance valve technologies, prioritizing safety and sustainability. These manufacturers also offer extensive testing and quality assurance processes, further solidifying their reputation as reliable providers of high-quality gas valves. In recent years, technological advancements have reshaped the landscape of natural gas valves. The integration of smart technology, such as sensors and actuators, allows for real-time monitoring and control of gas flow systems. These innovations lead to increased efficiency and safety, as potential issues can be identified and addressed before escalating. Moreover, smart valves contribute to the optimization of energy consumption, aligning with global efforts towards sustainable energy solutions. From a consumer's perspective, purchasing decisions should be informed by a comprehensive understanding of valve specifications, intended applications, and the reputation of manufacturers. Consulting with certified technicians or engineers can provide valuable insights into suitable valve selections, installation practices, and maintenance procedures, thus enhancing both safety and performance. In summary, the intricacies of natural gas valve systems are underscored by a confluence of technical expertise, rigorously upheld safety standards, and innovative advancements. As the demand for natural gas continues to rise, so does the responsibility to ensure that the integral components of its distribution, like gas valves, meet the highest thresholds of quality and reliability. By embracing the latest technologies and adhering to established guidelines, manufacturers not only safeguard the integrity of these systems but also contribute to a safer, more sustainable future.

Trustworthiness in the context of natural gas valves extends beyond the product itself to encompass the reputation of the manufacturers and suppliers. Leading companies invest significantly in research and development to innovate and enhance valve technologies, prioritizing safety and sustainability. These manufacturers also offer extensive testing and quality assurance processes, further solidifying their reputation as reliable providers of high-quality gas valves. In recent years, technological advancements have reshaped the landscape of natural gas valves. The integration of smart technology, such as sensors and actuators, allows for real-time monitoring and control of gas flow systems. These innovations lead to increased efficiency and safety, as potential issues can be identified and addressed before escalating. Moreover, smart valves contribute to the optimization of energy consumption, aligning with global efforts towards sustainable energy solutions. From a consumer's perspective, purchasing decisions should be informed by a comprehensive understanding of valve specifications, intended applications, and the reputation of manufacturers. Consulting with certified technicians or engineers can provide valuable insights into suitable valve selections, installation practices, and maintenance procedures, thus enhancing both safety and performance. In summary, the intricacies of natural gas valve systems are underscored by a confluence of technical expertise, rigorously upheld safety standards, and innovative advancements. As the demand for natural gas continues to rise, so does the responsibility to ensure that the integral components of its distribution, like gas valves, meet the highest thresholds of quality and reliability. By embracing the latest technologies and adhering to established guidelines, manufacturers not only safeguard the integrity of these systems but also contribute to a safer, more sustainable future.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024