2 月 . 14, 2025 10:06

Back to list

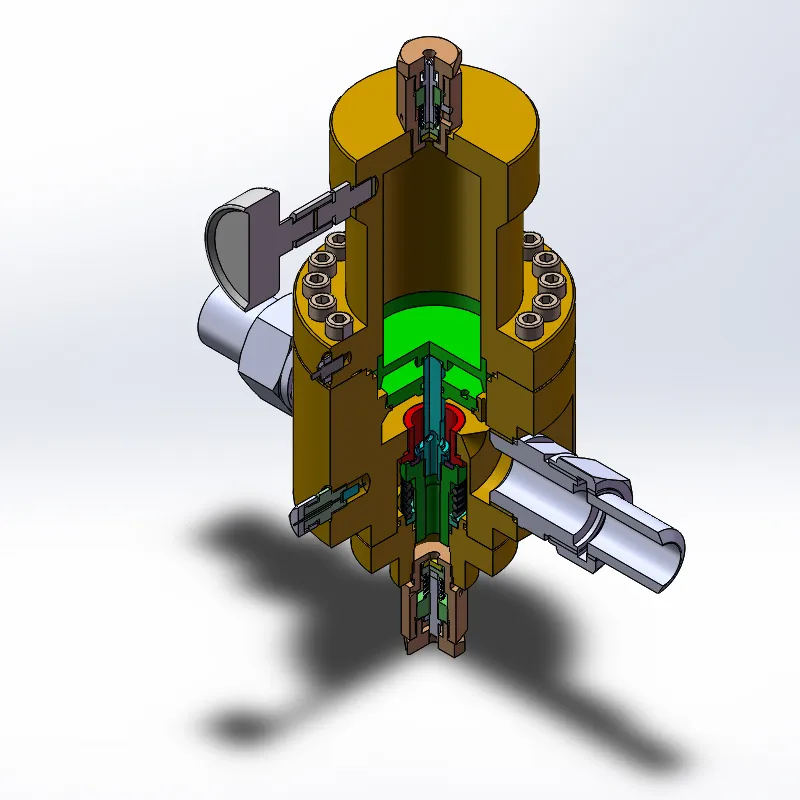

منظمات الضغط العالي

High-pressure systems have become indispensable tools across various industries due to their versatility and efficiency. These systems, which encompass pumps, hoses, and nozzles, play crucial roles in applications ranging from industrial cleaning to fluid control in manufacturing processes. Given their significance, understanding the nuances of these systems can enhance operational efficiency and safety.

The demand for high-pressure systems has led to advancements in technology that prioritize sustainability and efficiency. Modern high-pressure pumps are designed to maximize productivity with minimal environmental footprint. These innovations include energy-efficient motors and systems that recycle water during cleaning processes, reducing waste and operational costs. Being up to date with such advancements not only enhances expertise but also positions businesses as responsible and forward-thinking entities, gaining trust in markets increasingly concerned with environmental impact. In working with high-pressure systems, authority and trust are built through certification and compliance with industry standards. Organizations that diligently comply with global safety standards and regulations establish themselves as reliable partners. Certifications from organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) are markers of quality and safety that reassure clients and partners of a firm's expertise. Experience in handling high-pressure systems is deeply intertwined with technical knowledge and field practice. Consistently applying best practices and learning from hands-on applications refine operational skills. Whether it's selecting the appropriate nozzle size or maintaining an optimal pressure range for specific materials, experiential learning enhances an operator's ability to make informed decisions swiftly and accurately. In conclusion, the deployment of high-pressure systems across industries emphasizes the need for expertise, operational safety, technological advancement, and adherence to standards. Firms that invest in these areas not only fortify their market position but also drive operational excellence, ensuring they meet client expectations effectively. By showcasing competence and responsibility, they foster an environment of trust and reliability, key components for sustained success in the ever-evolving industrial landscape.

The demand for high-pressure systems has led to advancements in technology that prioritize sustainability and efficiency. Modern high-pressure pumps are designed to maximize productivity with minimal environmental footprint. These innovations include energy-efficient motors and systems that recycle water during cleaning processes, reducing waste and operational costs. Being up to date with such advancements not only enhances expertise but also positions businesses as responsible and forward-thinking entities, gaining trust in markets increasingly concerned with environmental impact. In working with high-pressure systems, authority and trust are built through certification and compliance with industry standards. Organizations that diligently comply with global safety standards and regulations establish themselves as reliable partners. Certifications from organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI) are markers of quality and safety that reassure clients and partners of a firm's expertise. Experience in handling high-pressure systems is deeply intertwined with technical knowledge and field practice. Consistently applying best practices and learning from hands-on applications refine operational skills. Whether it's selecting the appropriate nozzle size or maintaining an optimal pressure range for specific materials, experiential learning enhances an operator's ability to make informed decisions swiftly and accurately. In conclusion, the deployment of high-pressure systems across industries emphasizes the need for expertise, operational safety, technological advancement, and adherence to standards. Firms that invest in these areas not only fortify their market position but also drive operational excellence, ensuring they meet client expectations effectively. By showcasing competence and responsibility, they foster an environment of trust and reliability, key components for sustained success in the ever-evolving industrial landscape.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024