2 月 . 16, 2025 13:26

Back to list

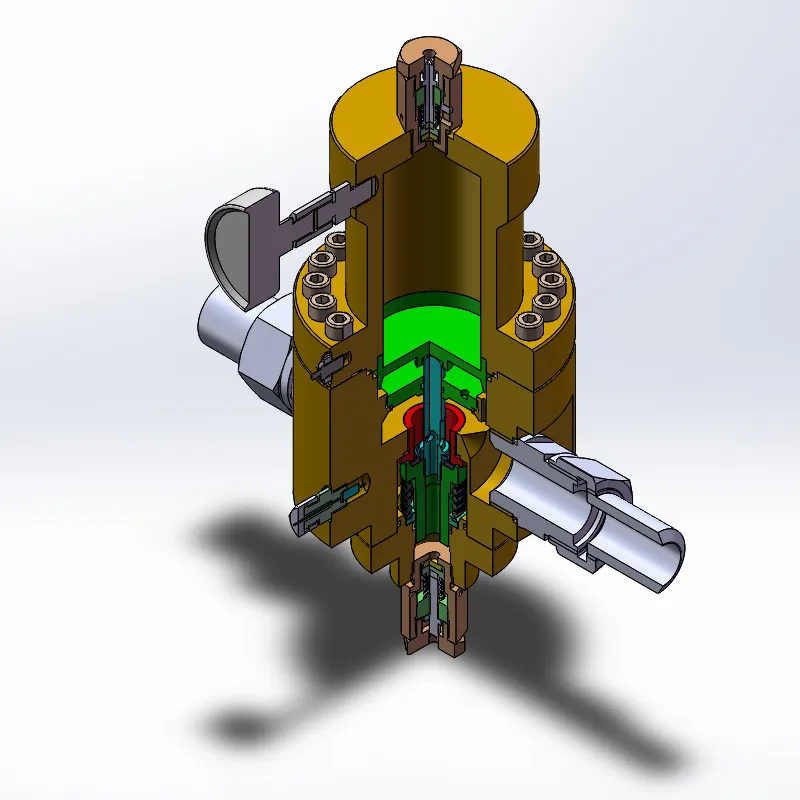

صمام تخفيض ضغط الغاز

Gas pressure reduction valves, often referred to in Arabic as [صمام تخفيض ضغط الغاز], play an indispensable role in numerous industrial and commercial applications. These valves are designed to regulate and stabilize the pressure within a gas system, ensuring operational safety and efficiency. A sophisticated understanding of these crucial components not only enhances user safety but also elevates energy efficiency and prolongs equipment lifespan.

Real-world experience highlights the importance of regular maintenance and inspections. Even the most reliable valves require periodic checks to ensure their components, such as springs and diaphragms, remain in optimum condition. Field professionals assert that a proactive maintenance schedule can drastically reduce the risk of unexpected failures, thus safeguarding operations against costly downtime. In tandem with reliability and efficiency, trustworthiness is cemented through a robust after-sales service. Successful companies extend comprehensive support, offering installation guidance, troubleshooting assistance, and replacement parts. This level of customer support not only underlines their commitment to quality but also ensures that users have access to expert knowledge and resources at all times. In conclusion, the role of the gas pressure reduction valve is both vital and multifaceted. From ensuring safe operations by preventing over-pressurization to enhancing system performance through precise control, these valves are a cornerstone of modern gas systems. As industry standards evolve, continuous advancements in valve technology, supported by expert insights and authoritative guidelines, will drive future innovations in this field. Users seeking to optimize their systems will benefit from partnering with trusted manufacturers and leveraging cutting-edge technology to ensure safety and efficiency.

Real-world experience highlights the importance of regular maintenance and inspections. Even the most reliable valves require periodic checks to ensure their components, such as springs and diaphragms, remain in optimum condition. Field professionals assert that a proactive maintenance schedule can drastically reduce the risk of unexpected failures, thus safeguarding operations against costly downtime. In tandem with reliability and efficiency, trustworthiness is cemented through a robust after-sales service. Successful companies extend comprehensive support, offering installation guidance, troubleshooting assistance, and replacement parts. This level of customer support not only underlines their commitment to quality but also ensures that users have access to expert knowledge and resources at all times. In conclusion, the role of the gas pressure reduction valve is both vital and multifaceted. From ensuring safe operations by preventing over-pressurization to enhancing system performance through precise control, these valves are a cornerstone of modern gas systems. As industry standards evolve, continuous advancements in valve technology, supported by expert insights and authoritative guidelines, will drive future innovations in this field. Users seeking to optimize their systems will benefit from partnering with trusted manufacturers and leveraging cutting-edge technology to ensure safety and efficiency.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024