2 月 . 15, 2025 08:15

Back to list

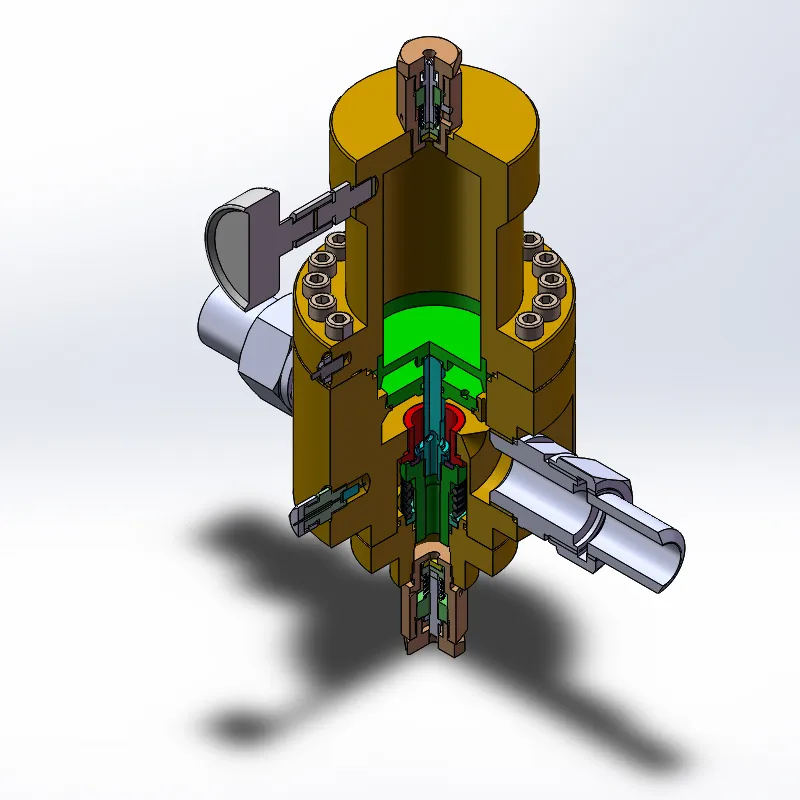

RTZB-15/0.2Medium Pressure Into Account Pressure Regulator

Harnessing the power of precise flow control, electric valves have revolutionized various industries by offering a high degree of reliability and performance. With technological advances and a growing emphasis on energy-efficient and automated systems, electric valves are no longer just an option but a necessity for modern infrastructure.

For professionals considering integrating electric valves into their systems, understanding the specific requirements and capabilities of these devices is crucial. Size, material construction, pressure norms, and electric actuator types are primary considerations. Selecting the right valve is a meticulous process, often requiring consultation with specialists who can provide insights based on empirical evidence and industry standards. While electric valves offer numerous advantages, it is vital for companies to maintain proper training for personnel who will be interacting with this technology. Ensuring that team members understand operation protocols and safety measures amplifies the benefits associated with electric valve systems. Companies investing in this technology should also focus on maintaining robust customer support infrastructures to assist with any troubleshooting or technical inquiries. As we look toward future trends, the evolution of electric valves is geared towards further integration with digital ecosystems. Innovations in artificial intelligence and machine learning are expected to drive the next wave of advancements in electric valve technology, facilitating predictive analytics and greater automation. As industries worldwide strive for increased efficiency and sustainability, the role of electric valves will undoubtedly become even more critical. In conclusion, the strategic implementation of electric valves across industrial platforms not only showcases their importance in the modern era but also highlights the continuous potential for growth and development in this field. By focusing on real-world applications, expert innovations, authoritative benchmarks, and trustworthy practices, electric valve technology continues to secure its position at the forefront of industrial evolution.

For professionals considering integrating electric valves into their systems, understanding the specific requirements and capabilities of these devices is crucial. Size, material construction, pressure norms, and electric actuator types are primary considerations. Selecting the right valve is a meticulous process, often requiring consultation with specialists who can provide insights based on empirical evidence and industry standards. While electric valves offer numerous advantages, it is vital for companies to maintain proper training for personnel who will be interacting with this technology. Ensuring that team members understand operation protocols and safety measures amplifies the benefits associated with electric valve systems. Companies investing in this technology should also focus on maintaining robust customer support infrastructures to assist with any troubleshooting or technical inquiries. As we look toward future trends, the evolution of electric valves is geared towards further integration with digital ecosystems. Innovations in artificial intelligence and machine learning are expected to drive the next wave of advancements in electric valve technology, facilitating predictive analytics and greater automation. As industries worldwide strive for increased efficiency and sustainability, the role of electric valves will undoubtedly become even more critical. In conclusion, the strategic implementation of electric valves across industrial platforms not only showcases their importance in the modern era but also highlights the continuous potential for growth and development in this field. By focusing on real-world applications, expert innovations, authoritative benchmarks, and trustworthy practices, electric valve technology continues to secure its position at the forefront of industrial evolution.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024