2 月 . 15, 2025 05:59

Back to list

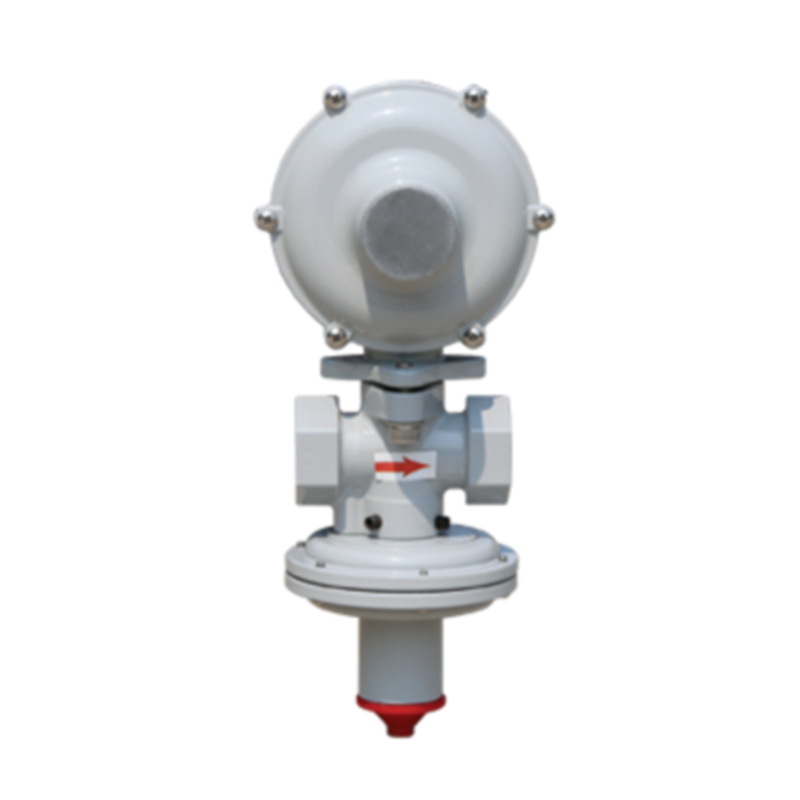

Gas Pressure Regulator Box/Cabinet

The efficiency and reliability of gas filters are pivotal in industries where air quality and safety are non-negotiable. From industrial manufacturing plants to residential settings, the need for a robust gas filtering system ensures that environments remain uncontaminated, clear, and compliant with health standards.

Expert engineers and industrial hygienists often recommend a multifaceted approach encompassing pre-filtration, main filtration, and post-filtration stages to achieve superior air quality. Pre-filtration captures larger debris, thus extending the lifespan of the main filter. The main filtration stage engages at the chemical level, while post-filtration might include advanced techniques such as HEPA (High-Efficiency Particulate Air) filtration to ensure any remaining trace particles are effectively removed. In contexts such as wastewater treatment plants, gas filters are indispensable in controlling malodorous emissions and reducing volatile organic compounds (VOCs) that can pose significant health risks. Filters engineered for specific use cases such as sulfur recovery or off-gas processing can thus greatly enhance the safety and comfort of industrial environments. With considerations of authoritativeness, manufacturers of gas filters are leading innovation by integrating smart technology into their design. IoT-enabled gas filters, for example, offer real-time monitoring of air quality and filter performance, allowing operators to schedule maintenance proactively and ensure optimal filter functioning without relying solely on periodic checks. Trustworthiness remains the cornerstone of gas filter application. Certification and compliance with international standards such as ISO 8573 for compressed air purity and ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) standards affirm the reliability of a gas filter product. These certifications are not merely labels but are indicative of a filter's ability to meet stringent efficacy and safety requirements consistently. In conclusion, the deployment of gas filters is crucial across various sectors. Experienced professionals drive the innovation and implementation of effective filter systems, ensuring that their expertise translates into practical solutions that uphold high standards of environmental safety and operational efficiency. Employing authoritative and credible gas filters provides trust and confidence to operators, while maintaining a commitment to health and safety regulations. As air quality continues to be a significant concern in industrial operations and even more so in residential spaces, the relevance and importance of an optimal gas filtration strategy cannot be overstated.

Expert engineers and industrial hygienists often recommend a multifaceted approach encompassing pre-filtration, main filtration, and post-filtration stages to achieve superior air quality. Pre-filtration captures larger debris, thus extending the lifespan of the main filter. The main filtration stage engages at the chemical level, while post-filtration might include advanced techniques such as HEPA (High-Efficiency Particulate Air) filtration to ensure any remaining trace particles are effectively removed. In contexts such as wastewater treatment plants, gas filters are indispensable in controlling malodorous emissions and reducing volatile organic compounds (VOCs) that can pose significant health risks. Filters engineered for specific use cases such as sulfur recovery or off-gas processing can thus greatly enhance the safety and comfort of industrial environments. With considerations of authoritativeness, manufacturers of gas filters are leading innovation by integrating smart technology into their design. IoT-enabled gas filters, for example, offer real-time monitoring of air quality and filter performance, allowing operators to schedule maintenance proactively and ensure optimal filter functioning without relying solely on periodic checks. Trustworthiness remains the cornerstone of gas filter application. Certification and compliance with international standards such as ISO 8573 for compressed air purity and ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) standards affirm the reliability of a gas filter product. These certifications are not merely labels but are indicative of a filter's ability to meet stringent efficacy and safety requirements consistently. In conclusion, the deployment of gas filters is crucial across various sectors. Experienced professionals drive the innovation and implementation of effective filter systems, ensuring that their expertise translates into practical solutions that uphold high standards of environmental safety and operational efficiency. Employing authoritative and credible gas filters provides trust and confidence to operators, while maintaining a commitment to health and safety regulations. As air quality continues to be a significant concern in industrial operations and even more so in residential spaces, the relevance and importance of an optimal gas filtration strategy cannot be overstated.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024