1 月 . 25, 2025 05:56

Back to list

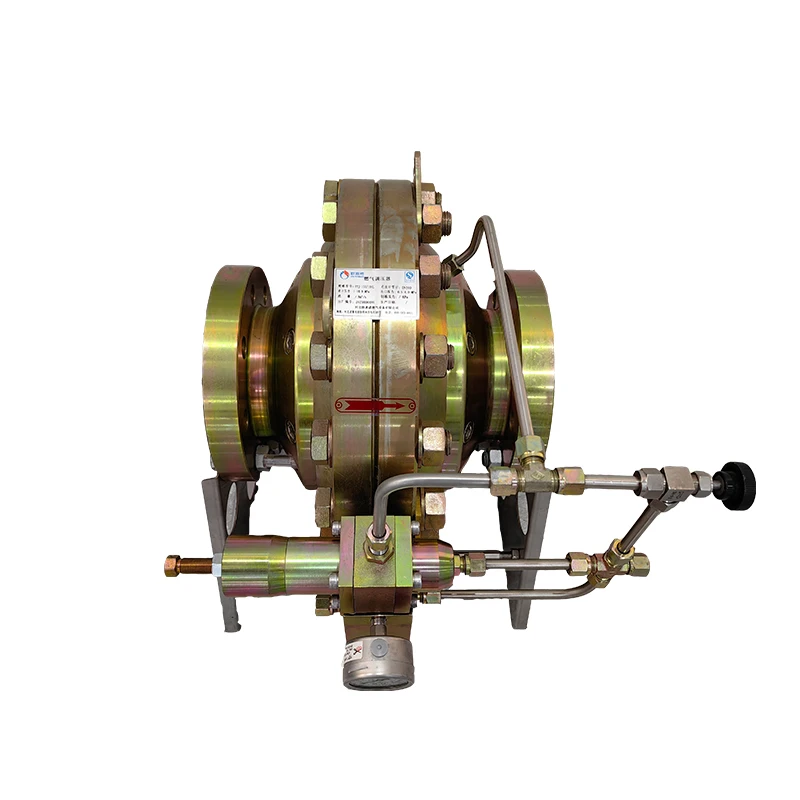

RTZ1-*/GQ Series Gas Pressure Regulator

Gas pressure vessels have become indispensable components in various industrial applications due to their ability to safely store and transport gases under pressure. These robust structures are crucial in sectors such as chemical processing, energy generation, and even healthcare. This article delves into the multifaceted aspects of gas pressure vessels, providing a comprehensive guide that not only highlights their industrial significance but also serves as a valuable resource for professionals seeking to deepen their understanding.

One of the compelling aspects of expertise in this field is the continuous evolution of safety measures. Recent innovations include advanced monitoring systems that utilize IoT technology and AI algorithms to predict potential failures before they occur. These systems enhance the operational trustworthiness of pressure vessels by offering real-time data and predictive analytics to prevent catastrophic failures. For businesses invested in or reliant on gas pressure vessels, understanding the lifecycle cost and maintenance scheduling is crucial. While initial investments can be substantial, a focus on preventive maintenance and regular inspections can reduce long-term expenses and enhance the vessel’s lifespan. Such practices not only safeguard the asset but also ensure compliance with regulatory standards, reinforcing the trust placed in these essential tools. Gas pressure vessels also hold significant environmental implications. As industries move towards sustainability, there is a focus on minimizing emissions and maximizing efficiency. Professionals engaged in the production and maintenance of these vessels are increasingly expected to integrate eco-friendly practices and innovations that minimize the carbon footprint, without compromising on safety or efficacy. Conclusively, gas pressure vessels are a testament to engineering prowess, demanding an intersection of experience, expertise, authoritativeness, and trustworthiness. As a professional, engaging with this field provides an opportunity to contribute to technological advancements and enhance industrial safety standards. For those seeking to navigate the complexities of gas pressure vessels, a commitment to continuous learning and adherence to best practices remains paramount. Whether you are an engineer, safety officer, or business leader, a deep-seated knowledge of these pressure vessels will enable you to make informed decisions that drive operational excellence and sustainability.

One of the compelling aspects of expertise in this field is the continuous evolution of safety measures. Recent innovations include advanced monitoring systems that utilize IoT technology and AI algorithms to predict potential failures before they occur. These systems enhance the operational trustworthiness of pressure vessels by offering real-time data and predictive analytics to prevent catastrophic failures. For businesses invested in or reliant on gas pressure vessels, understanding the lifecycle cost and maintenance scheduling is crucial. While initial investments can be substantial, a focus on preventive maintenance and regular inspections can reduce long-term expenses and enhance the vessel’s lifespan. Such practices not only safeguard the asset but also ensure compliance with regulatory standards, reinforcing the trust placed in these essential tools. Gas pressure vessels also hold significant environmental implications. As industries move towards sustainability, there is a focus on minimizing emissions and maximizing efficiency. Professionals engaged in the production and maintenance of these vessels are increasingly expected to integrate eco-friendly practices and innovations that minimize the carbon footprint, without compromising on safety or efficacy. Conclusively, gas pressure vessels are a testament to engineering prowess, demanding an intersection of experience, expertise, authoritativeness, and trustworthiness. As a professional, engaging with this field provides an opportunity to contribute to technological advancements and enhance industrial safety standards. For those seeking to navigate the complexities of gas pressure vessels, a commitment to continuous learning and adherence to best practices remains paramount. Whether you are an engineer, safety officer, or business leader, a deep-seated knowledge of these pressure vessels will enable you to make informed decisions that drive operational excellence and sustainability.

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024