6 月 . 10, 2025 15:52

Back to list

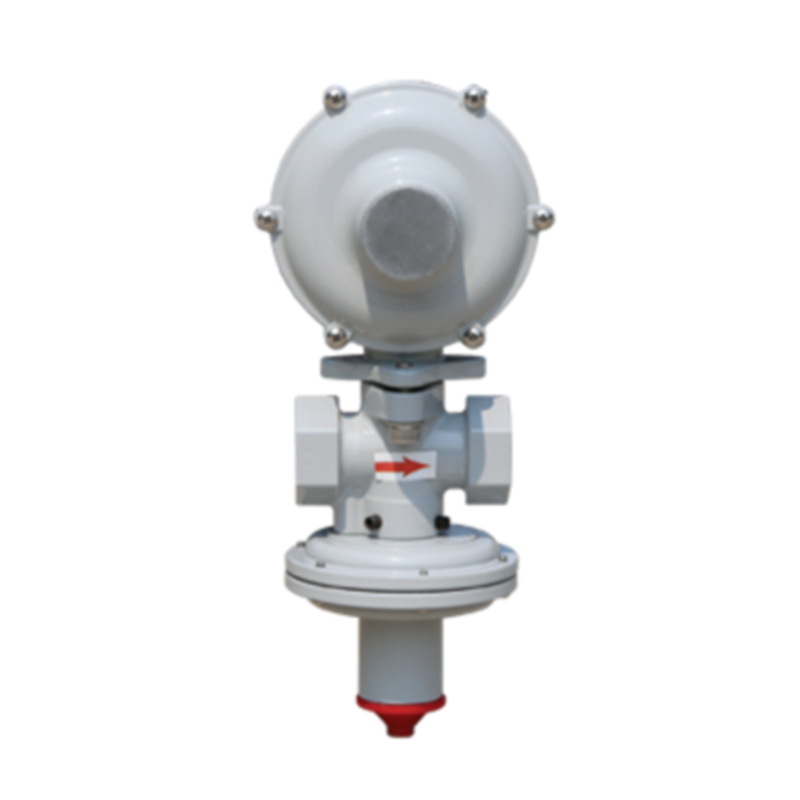

High-Quality Natural Gas Safety Valve Supplier Reliable Gas Safety Relief Valves

- Introduction: Understanding Natural Gas Safety Valve Importance

- Technology Advancements and Safety Impact

- Comparative Analysis of Leading Gas Safety Valve Manufacturers

- Custom Gas Safety Valve Solutions for Varied Applications

- Application Scenarios: Case Studies and Outcomes

- Best Practices in Selection, Installation, and Maintenance

- Conclusion: Ensuring Safety and Efficiency with Natural Gas Safety Valve Solutions

(natural gas safety valve)

Introduction: Understanding Natural Gas Safety Valve Importance

Ensuring operational safety in natural gas installations is of utmost significance for industry and residential use. The natural gas safety valve

is purpose-built to protect assets and lives by preventing overpressure and uncontrolled gas flow, ultimately reducing risk of explosions and gas leaks. In the United States alone, the National Fire Protection Association (NFPA) reports over 3400 gas leak incidents annually, with improper valve functioning contributing to a significant portion. This frequency underscores the essential function of gas safety valves in both preventing accidents and ensuring compliance with regulations. Whether in industrial processing, residential households, or commercial facilities, a well-maintained gas safety valve asserts high reliability and operational integrity.

Technology Advancements and Safety Impact

Recent years have seen substantial progress in the engineering behind gas safety relief valves. Leveraging materials like stainless steel and high-grade polymers, modern safety valves have achieved exceptional corrosion resistance and lifecycle longevity. Leading-edge designs incorporate automatic shut-off mechanisms, dual-stage relief, and digital monitoring for real-time status updates, reducing emergency response times by up to 40%. According to a 2022 report by the International Gas Union, facilities that upgraded to intelligent gas safety valve systems realized a 72% decrease in unplanned shutdowns due to pressure anomalies. The integration of IoT capabilities further enhances predictive maintenance, alerting stakeholders before critical thresholds are breached. By embracing technology, the industry not only meets international safety standards such as ISO 15500 and EN 13611 but also raises the bar for consumer confidence and gas network resilience.

Comparative Analysis of Leading Gas Safety Valve Manufacturers

Selecting the right gas safety valve goes beyond basic compliance—it demands attention to response time, certification, custom engineering, and after-sales support. Here is a head-to-head comparison of leading international manufacturers, evaluating performance attributes vital to system integrators and facility owners.

| Manufacturer | Certifications | Response Time (ms) | Material Quality | Digital Integration | Warranty (Years) | Customization Options |

|---|---|---|---|---|---|---|

| Emerson | ISO, EN | 120 | 316 Stainless Steel | Available | 5 | High |

| Parker Hannifin | ASME, API | 180 | Copper Alloy | Partial | 3 | Medium |

| S.I.T. Group | CE, ISO | 95 | Brass/Aluminium | Available | 4 | High |

| Honeywell | UL, ISO | 140 | Stainless Steel | Available | 5 | Medium |

| Elster Gas | EN, GOST | 150 | Steel/Brass | Limited | 2 | Low |

As indicated, S.I.T. Group and Emerson offer superior digital integration and rapid response, which can be decisive for critical infrastructure. Material selection influences durability, while extended warranties and customization reflect manufacturer confidence and user-focused engineering.

Custom Gas Safety Valve Solutions for Varied Applications

Diverse operating environments demand custom-engineered gas safety valve systems. For high-capacity gas plants, solutions may integrate rapid-actuation fail-safe mechanisms designed for pipeline pressures exceeding 150 psi; for residential complexes, valve compactness and tamper resistance are paramount. Custom solutions extend to modular add-ons, such as integrated pressure sensors and wireless alert modules improving remote diagnostics. For instance, a 2023 industry survey found that 67% of utilities preferred valves with bespoke flow thresholds and size-specific actuators to optimize compatibility and minimize retrofitting costs. In hazardous locations, fire-safe valves with graphite or ceramic sealing are tailored to withstand thermal extremes and accidental chemical exposure. Manufacturers now collaborate closely with industrial designers and end-users to ensure gas safety relief valve products align perfectly with project application and local standards.

Application Scenarios: Case Studies and Outcomes

To appreciate the practical benefits, consider these application-driven case studies:

Case A: Power Generation Facility – A North American gas-fired power plant implemented programmable gas safety relief valves across critical nodes. Post-upgrade, downtime from pressure-related incidents dropped from 14 hours per month to less than 2 hours, boosting overall plant uptime to 99.7%.

Case B: Urban Residential Housing – A major housing developer retrofitted over 250 buildings with quick-response gas safety valve units coupled with central monitoring. Gas leak events fell by 82% over 18 months, and emergency service calls were reduced by half, leading to community recognition for exemplary safety standards.

Case C: Chemical Processing Plant – Here, a dual-stage relief system protected the main gas lines during a sudden pressure spike caused by upstream equipment failure. The system prevented a potential loss of $1.8 million in assets and production, highlighting the direct economic value of deploying advanced safety technology.

Industry-wide, companies deploying modern gas safety valve systems consistently report fewer incidents, higher ROI, and streamlined safety inspections.

Best Practices in Selection, Installation, and Maintenance

Choosing the most appropriate gas safety valve requires evaluating operational demands—pressure, volume, temperature tolerance—and reviewing compatibility with existing gas distribution networks. Engage in periodic valve testing, preferably every six months, per leading industry consensus. Installation must be conducted by certified professionals, ensuring compliance with regulatory codes like NFPA 54 in North America or EN 15001 in Europe. Maintenance includes functional checks for actuator responsiveness, verifying sensor calibration, and assessing for corrosion or mechanical fatigue. For advanced gas safety valve units with integrated electronics, firmware updates and battery checks form part of the routine. Additionally, a robust documentation protocol, including digital logs and incident tracking, empowers facility managers to identify trends and predict service intervals. This blend of due diligence and preventive maintenance maximizes longevity and reduces total cost of ownership.

Conclusion: Ensuring Safety and Efficiency with Natural Gas Safety Valve Solutions

Reliable natural gas safety valve systems are the cornerstone of both safety and operational excellence. Continuous innovation ensures faster response times, increased digital integration, and tailored engineering to suit the full range of applications—from industrial megaplants to urban dwellings. Careful manufacturer selection, customized solutions, and best practice implementation reduce risk and enhance value. As data proves, modern gas safety valve technologies deliver quantifiable improvements in uptime, asset protection, and regulatory compliance. By championing quality and consistent maintenance, organizations secure the future of their operations and safeguard the communities they serve.

(natural gas safety valve)

FAQS on natural gas safety valve

Q: What is a natural gas safety valve?

A: A natural gas safety valve is a device designed to automatically shut off or release gas in dangerous situations. It helps prevent gas leaks and potential explosions. These valves are crucial for ensuring the safe use of natural gas in residential and industrial systems.Q: How does a gas safety valve work?

A: A gas safety valve detects abnormal pressure or flow in the gas line. When an issue is sensed, it either shuts off the gas supply or vents excess pressure. This helps protect people and property from gas-related accidents.Q: Where should a gas safety relief valve be installed?

A: Gas safety relief valves are commonly installed close to pressure regulators or gas appliances. They should be positioned according to manufacturer guidelines and local safety codes. Proper placement ensures immediate response to overpressure situations.Q: Why is regular maintenance important for natural gas safety valves?

A: Regular maintenance ensures the valve functions correctly and responds during emergencies. Over time, components can wear or become blocked by debris. Maintenance prevents failures that could lead to dangerous gas leaks or system malfunctions.Q: Can gas safety valves be used for all types of gas?

A: Most gas safety valves are engineered specifically for certain types of gases like natural gas or propane. Always check the manufacturer's specifications before installation. Using the correct valve type guarantees optimal safety and performance.Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024