1 月 . 16, 2025 02:06

Back to list

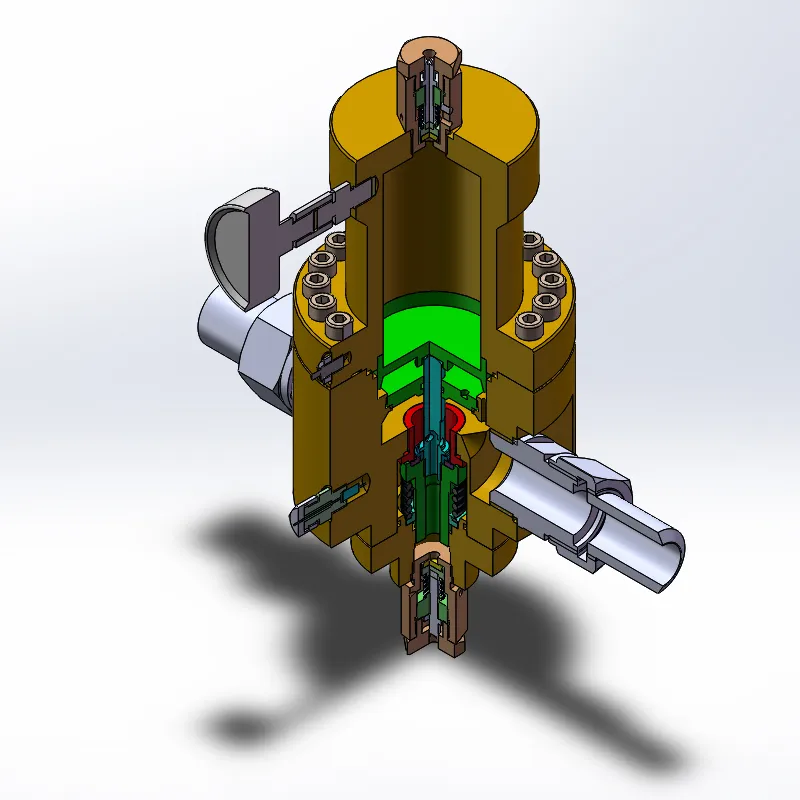

natural gas pressure reducer

Natural gas pressure reducers are essential components in the efficient and safe management of gas systems across various industries. These devices play a pivotal role in regulating and maintaining the desired pressure levels of natural gas as it travels from high-pressure pipelines to the point of use, ensuring safety, performance, and efficiency.

Trustworthiness is further cemented through real-world experience. Professionals who install and maintain natural gas pressure reducers consistently rely on feedback loops to enhance the reliability and performance of these devices. Real-world data and case studies offer invaluable insights into how these components perform over time under varied conditions. Consequently, customers can make informed decisions based on empirical evidence and industry-recognized best practices. From an experience standpoint, those in the field attest to the critical function that effective pressure reduction plays in overall system efficiency. When natural gas is managed correctly, it results in optimal combustion, reduced emissions, and improved operational efficiency, translating to significant cost savings and a lessened environmental impact. Moreover, innovations like automated monitoring systems have been introduced, allowing users to track performance and make adjustments remotely, thus adding an additional layer of control and reliability. To sum up, whether you are overseeing a small-scale heating system or a massive industrial operation, understanding the intricacies of natural gas pressure reducers is essential. Their role in maintaining safe and efficient gas delivery cannot be overstated. By integrating advanced engineering expertise, rigorous testing, and real-world validation, these devices epitomize the balance between safety, performance, and innovation in natural gas management.

Trustworthiness is further cemented through real-world experience. Professionals who install and maintain natural gas pressure reducers consistently rely on feedback loops to enhance the reliability and performance of these devices. Real-world data and case studies offer invaluable insights into how these components perform over time under varied conditions. Consequently, customers can make informed decisions based on empirical evidence and industry-recognized best practices. From an experience standpoint, those in the field attest to the critical function that effective pressure reduction plays in overall system efficiency. When natural gas is managed correctly, it results in optimal combustion, reduced emissions, and improved operational efficiency, translating to significant cost savings and a lessened environmental impact. Moreover, innovations like automated monitoring systems have been introduced, allowing users to track performance and make adjustments remotely, thus adding an additional layer of control and reliability. To sum up, whether you are overseeing a small-scale heating system or a massive industrial operation, understanding the intricacies of natural gas pressure reducers is essential. Their role in maintaining safe and efficient gas delivery cannot be overstated. By integrating advanced engineering expertise, rigorous testing, and real-world validation, these devices epitomize the balance between safety, performance, and innovation in natural gas management.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024