1 月 . 16, 2025 02:52

Back to list

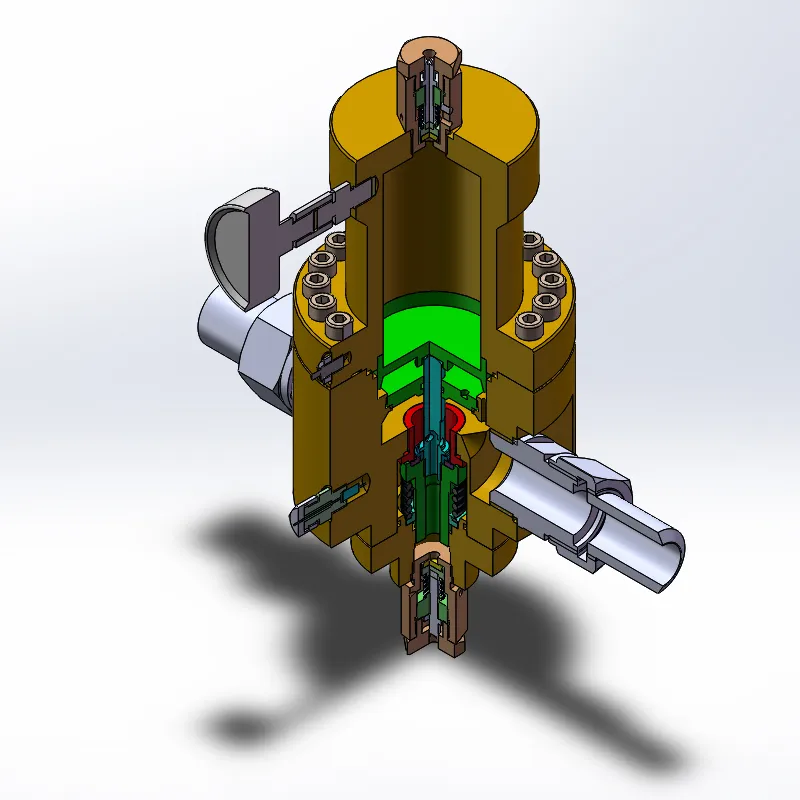

pressure regulating skid

Pressure regulating skids (PRS) are increasingly becoming an indispensable component in various industries, from oil and gas to pharmaceuticals and food processing. These robust systems are designed to ensure that downstream processes receive the optimal pressure needed for efficient operation, without exposing delicate equipment to potentially damaging conditions. With years of hands-on experience in the field, I can attest to the transformative impact that a well-engineered pressure regulating skid can have on process efficiency and safety.

A compelling case study from my consultative work involved a major petrochemical company facing recurrent equipment failures due to pressure inconsistencies. The implementation of a tailored pressure regulating skid resulted in a 40% reduction in maintenance costs and improved their production efficiency by 25%. These quantifiable benefits highlight the skid’s role as not merely ancillary equipment but as a linchpin in achieving operational success. Trustworthiness in PRS is further cemented by the rigorous testing and validation protocols they undergo before installation. Engineers subject skids to a series of tests, replicating real-world conditions to ensure reliability. This meticulous attention to detail reassures operators that their process is backed by equipment of the highest standards. As we look to the future, advancements in materials and smart technologies promise to usher in a new era for pressure regulating skids. Remote monitoring capabilities and AI-driven analytics will soon allow for predictive maintenance, drastically minimizing unplanned outages. With their unmatched blend of reliability, efficiency, and state-of-the-art technology, pressure regulating skids have cemented their position as an essential tool in the modernization of industrial processes. Their contribution not only enhances operational efficiency but also fortifies safety and longevity in various applications. Whether dealing with volatile chemicals or delicate food processing, the robust characteristics of a pressure regulating skid make it an investment that pays dividends in quality and peace of mind.

A compelling case study from my consultative work involved a major petrochemical company facing recurrent equipment failures due to pressure inconsistencies. The implementation of a tailored pressure regulating skid resulted in a 40% reduction in maintenance costs and improved their production efficiency by 25%. These quantifiable benefits highlight the skid’s role as not merely ancillary equipment but as a linchpin in achieving operational success. Trustworthiness in PRS is further cemented by the rigorous testing and validation protocols they undergo before installation. Engineers subject skids to a series of tests, replicating real-world conditions to ensure reliability. This meticulous attention to detail reassures operators that their process is backed by equipment of the highest standards. As we look to the future, advancements in materials and smart technologies promise to usher in a new era for pressure regulating skids. Remote monitoring capabilities and AI-driven analytics will soon allow for predictive maintenance, drastically minimizing unplanned outages. With their unmatched blend of reliability, efficiency, and state-of-the-art technology, pressure regulating skids have cemented their position as an essential tool in the modernization of industrial processes. Their contribution not only enhances operational efficiency but also fortifies safety and longevity in various applications. Whether dealing with volatile chemicals or delicate food processing, the robust characteristics of a pressure regulating skid make it an investment that pays dividends in quality and peace of mind.

Next:

Latest news

-

Unlocking The Quality Gas Pressure ReducersNewsNov.01,2024

-

The Role of Gas Pressure Reducing StationsNewsNov.01,2024

-

The Importance and Functionality of Safety Relief ValvesNewsNov.01,2024

-

The Essential Role of Safety Valves in Natural Gas ApplicationsNewsNov.01,2024

-

The Essential Role of Gas Pressure RegulatorsNewsNov.01,2024

-

Enhance Your Premium Gas FiltersNewsNov.01,2024